Rear-end train collision

Quebec North Shore and Labrador Railway

freight train No. FCS 45 and train no. PH-475

Mile 131.68, Wacouna Subdivision

Near Mai, Quebec

The Transportation Safety Board of Canada (TSB) investigated this occurrence for the purpose of advancing transportation safety. It is not the function of the Board to assign fault or determine civil or criminal liability. This report is not created for use in the context of legal, disciplinary or other proceedings. See Ownership and use of content. Masculine pronouns and position titles may be used to signify all genders to comply with the Canadian Transportation Accident Investigation and Safety Board Act (S.C. 1989, c. 3).

Summary

On 14 July 1996, at approximately 1045 eastern daylight time, a Quebec North Shore and Labrador Railway (QNS&L) southward train collided with the tail end of a stationary train at Mile 131.68 of the Wacouna Subdivision. The last three rail cars of the stationary train derailed and were extensively damaged. The locomotive of the moving train was extensively damaged. The locomotive engineer of the moving train sustained minor injuries.

The Board determined that the collision occurred because the moving train was operated past a governing restrictive signal, at a speed at which the locomotive engineer was unable to stop short of the stationary equipment. The implementation of the major operational change to locomotive-engineer-only train operation without a comprehensive analysis of its impact and without the implementation of effective compensatory safety measures contributed to this occurrence.

Ce rapport est également disponible en français.

1.0 Factual Information

1.1 The Accident

Southward freight train No. PH-475 (train 475), crewed by a locomotive engineer and a locomotive engineer trainee, originated at Carol Lake, Labrador, Mile 36.6 of the Quebec North Shore and Labrador Railway (QNS&L) Northernland Subdivision, and was destined for Sept-Îles, Quebec, Mile 0.0 of the Wacouna Subdivision. Train 475 departed Carol Lake at 0340Footnote 1 and proceeded southward on the Northernland Subdivision for approximately 37 miles, entered the Wacouna Subdivision at Ross Bay Junction, Labrador, Mile 224.0, and continued southward for approximately 92 miles. At the advance signal to the north siding switch at Mai Station, Signal 132.6 at Mile 132.6, train 475 encountered a clear to stop signal indication, Canadian Rail Operating Rules (CROR) Rule 410. CROR Rule 410 states:

- NAME INDICATION

- Clear to Stop Proceed, preparing to stop at the next signal.

The locomotive engineer trainee made a minimum reduction automatic brake application and, shortly thereafter, the train experienced an undesired emergency brake application. Train 475 came to a stop with the rear end at Mile 131.68. The locomotive engineer contacted the rail traffic controller (RTC) by radio and advised him that train 475 had experienced an undesired emergency brake application and had stopped north of the north siding switch at Mai. He further advised the RTC that they could not recover the emergency brake application so he would be going back along the train to see what was wrong.

Southward freight train No. FCS 45 (train 45), crewed by a locomotive engineer, departed Carol Lake at 0650, proceeded south on the Northernland Subdivision to Ross Bay Junction and continued south on the Wacouna Subdivision. At approximately 1030, the RTC contacted the locomotive engineer as the train passed the south siding switch at Eric Station, Mile 137.3, approximately 5.6 miles behind the tail end of train 475, and advised him that train 475 was stopped in emergency just before Mai. The locomotive engineer of train 45 acknowledged the transmission from the RTC and continued southward. At Signal 134.2, Mile 134.2, train 45 encountered a clear to stop signal. At the next signal, Signal 132.6, Mile 132.6, train 45 encountered a restricting signal, CROR Rule 426. CROR Rule 426 states:

- NAME INDICATION

- Restricting Signal Proceed at restricted speed.

The CROR definition of restricted speed reads as follows:

A speed that will permit stopping within one-half the range of vision of equipment, also prepared to stop short of a switch not properly lined and in no case exceeding SLOW SPEED.

NOTE: When moving at restricted speed, be on the lookout for broken rails.

The CROR definition of slow speed reads as follows:

A speed not exceeding fifteen miles per hour.

In the vicinity of Mile 131.79, as train 45 negotiated a curve at approximately 30 mph, the locomotive engineer observed the rear of train 475 and initiated an emergency brake application. Thirteen seconds later, at approximately 1045, train 45 struck train 475, while travelling at approximately 20 mph. The locomotive engineer of train 45 remained in the locomotive cab during the impact.

QNS&L had instituted one-person crew train operation on 12 July 1996. The locomotive engineer of train 45 had operated trains north from Sept-Îles to Mai and Carol Lake alone and was on the return trip from Carol Lake to Mai at the time of the occurrence.

1.2 Injuries

The locomotive engineer of train 45 sustained injuries to his left thigh, right knee and tail bone.

1.3 Damage to Equipment

The last car of train 475 was damaged beyond economical recovery and the two cars ahead of it were extensively damaged. The lead locomotive of train 45 was severely damaged.

1.4 Train Information

1.4.1 Train 475

Train 475 consisted of 3 locomotives, 155 ore cars loaded with iron ore pellets and 1 empty ore car at the rear end. The train was equipped with a Digitair II end-of-train information system (ETIS). The end-of-train unit was mounted on the rear coupler of the last car. Reflectorized strips were applied to the end-of-train unit. A red reflectorized sign about 20 inches square was affixed to the rear-end ladder of the last car on the upper right-hand position as seen from behind. The train weighed approximately 17,450 tons and was approximately 5,600 feet in length. It had been operated without incident between Carol Lake and Mai.

1.4.2 Train 45

Train 45 consisted of 2 locomotives, 15 loaded cars and 41 empty cars. It weighed approximately 2,100 tons and was approximately 2,650 feet in length. Train 45 received a successful brake test at Carol Lake before departure. It was operated without incident between Carol Lake and the occurrence site.

1.5 Occurrence Site InformationFootnote 2

The Wacouna Subdivision extends north from Sept-Îles to Ross Bay Junction, a distance of 224 miles. From Ross Bay Junction, the Northernland Subdivision continues north to Carol Lake at Wabush, Labrador, an additional 36.6 miles. These subdivisions traverse remote territory. There are few public crossings between Sept-Îles and Wabush. Camps are maintained at various locations along the track to accommodate railway operation and maintenance personnel. The primary means of transportation throughout this territory is train or helicopter.

There are two sidings, two spurs and a back track at Mai for meeting, passing and storing trains. One siding is to the west of the main track and north of the bunkhouse; the other siding is to the east of the main track and south of the bunkhouse. It is common practice for southward trains arriving at Mai to be authorized to proceed south of the north siding switch, either on the main track or on the siding, up to the bunkhouse, to change crews. The bunkhouse is located at Mile 128.4. The north siding switch at Mai is at Mile 130.4. There is a distance of 2.0 miles between the north siding switch and the bunkhouse.

Approaching from the north, Signal 132.6 is located at the end of tangent track. It is a high-mast, single aspect signal equipped with an "R" letter sign and number identification sign. Both the number identification sign and the "R" letter sign were in good condition. Approaching Mile 131.68 (the point of impact) from the north, there is a three-degree curve to the left and a slight ascending grade of 0.2 per cent. Sight-lines from the point of contact north were limited by forest and track curvature to approximately 600 feet.

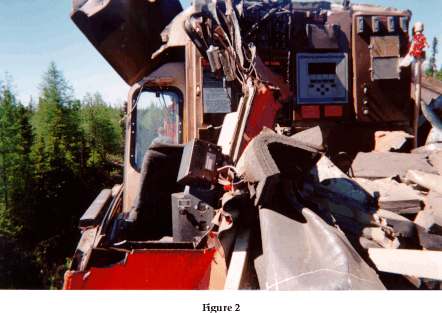

As a result of the collision, the last three cars of train 475 and the lead locomotive of train 45 derailed. The short hood of the locomotive was sheared off the frame and the cab was demolished, except for the small area encompassing the locomotive engineer's control console, seat and right-hand side wall up to the bottom of the window (see Figure 2).

1.6 Method of Train Control

The method of train control on the Wacouna Subdivision is the Centralized Traffic Control System (CTC) authorized by the CROR and supervised by the RTC located in Sept-Îles. Train movements are governed by signal indications. CTC has existed in its present form in Canada for approximately 45 years. CTC has been the method of train control on the Wacouna Subdivision since the track was built in the late 1950s. There was no form of automatic intervention associated with this method of train control, capable of maintaining positive train separation. Furthermore, there was no form of passive warning system associated with this method of train control to indicate a train's proximity to areas of restriction or other rolling stock.

1.7 Weather

The skies were clear and sunny, and visibility was good. The temperature at Sept-Îles, approximately 130 miles south, was 20 degrees Celsius.

1.8 Recorded Information

Locomotive event recorder data from the lead locomotive of train 45 were recovered. Despite severe damage sustained in the impact, the event recorder provided a complete data download. The data indicate that, at a time of 1044:46.2, there was an operator-initiated emergency brake application. Train speed was recorded as 30.1 mph. Between 1044:46.2 and 1044:59.2, 13 seconds, speed slowed by 9.9 mph to a recorded speed of 20.2 mph. At 1044:59.3, recorded speed suddenly decreased to 11.6 mph and a message was recorded that indicated "recorder reset or powered up." At 1045:04, speed was recorded at 0.0 mph. The train travelled a recorded distance of 0.092 mile, approximately 486 feet, between the emergency brake application at 1044:46.2 and the recorded speed of 0 mph at 1045:04.

The event recorder data indicate various manipulations of the locomotive throttle and dynamic brake between a recorded time of 1033:31 and the emergency brake application, at a recorded distance of 8.32 miles. In the two miles before the collision, the locomotives were taken out of powering mode and put into dynamic brake mode. The train had slowed from a recorded speed of 45 mph to a recorded speed of 30.1 mph in this distance.

1.9 Personnel Information

The locomotive engineer of train 45 and crew of train 475 were qualified for their positions and met fitness and rest standards established to ensure the safe operation of trains. The locomotive engineer of train 475 had operated trains on the QNS&L railway for over 20 years. The locomotive engineer of train 45 was also an experienced trainman with over 20 years of railway service.

1.10 Locomotive-Engineer-Only Train Operation

1.10.1 Business Plan

The railway indicated that the change to one-person train operation was for competitive reasons. QNS&L management indicated that some of their competitors were operating with one-person crews and that other non-competitor railways, such as Amtrak, had some one-person crew operations. QNS&L had contacted Amtrak and New Zealand Rail to review how those railways had modified their operations for one-person crews. In the case of Amtrak, the railway has limited the length of run to four hours when a train has one person in the operating cab. New Zealand Rail operates with one person in the operating cab; however, all its trains are scheduled. Employees know as much as a year in advance when they will be working.

Before the implementation of one-person train operation, railway representatives gave presentations to the Railway Association of Canada (RAC) and the regulator, Transport Canada, specifying their plans to negotiate for one-person operation and the particulars of how they intended to operate in a one-person crew environment. They also reported that they advised Transport Canada that it was their intention to begin one-person crew operations at the successful completion of contract negotiations with their operating union, the United Transportation Union (UTU). The railway reports to have solicited comment from both organizations and that Transport Canada responded with an indication that the railway's proposal was sound. Transport Canada maintains that it was not advised of the railway's intention to commence one-person crew operations at the successful completion of contract negotiations. Transport Canada indicates that it assessed the proposal as sound and that it advised the railway that it would need to see a much more thorough proposal before giving a conclusive opinion. Transport Canada reported that it did not see an issue with respect to rules compliance. Transport Canada maintained that it advised the railway that any proposed operation was expected to be as safe as the existing operation. In addition, Transport Canada recalls that it raised concerns with respect to pre-departure job briefings, rear view mirrors on locomotives, reset safety control operation and pull-by train inspections. Correspondence from the UTU to Transport Canada expressed the UTU's concerns about the safety of the operation of trains with one person in the operating cab. The official reply conveyed Transport Canada's position at the time, ". . . there are no federal regulations designating the number of persons to be employed on a train. Rather, crew size is a matter to be negotiated between the railway company and the unions representing the operating employees." Transport Canada also reports to have advised the union that ". . . regardless of the crew size, railway companies must comply with all operating rules or seek exemptions from such rules by explaining how they can do so in a safe manner."

1.10.2 Negotiation and Conciliation

On 11 July 1996, QNS&L and the UTU signed a collective agreement that included provisions to operate selected trains with one person in the operating cab of a locomotive and, in some cases, one-person crews. The following day, the railway began operating trains as per the new agreement.

The new collective agreement includes the following changes:

Article 16.01

The number of hours an employee is required to work before exercising the right to request rest while en route was increased from 10 to 12. The number of hours rest an employee may book at an away from home terminal was reduced from 9 to 7.

Article 16.03

Employees in train service are permitted to request a 20 minute nap between their 10th and 12th hour on duty. They must make a request of the RTC sufficiently in advance so as not to affect train traffic. To the extent possible, the RTC will authorize the employee to stop at the next station.

1.10.3 Implementation

The railway's preparation for one-person operation included identification of the CROR rules that normally require more than one crew member to comply with the rules and development of contingency plans to remain in compliance with one person in the locomotive cab. From this information, railway rules instructors developed a short training document and presentation. Locomotive engineers were required to attend an information session of approximately three hours' duration to discuss rules and other operating concerns before operating a train alone. There was no means of assessment used to evaluate the employees' knowledge of the information covered in these sessions. No exemptions to the existing operating rules were applied for by the railway. The railway indicated that CROR Rule 106 makes provision for the operation of trains with one person in the operating cab. CROR Rule 106, Crew Responsibilities, states, in part:

When a train is operated without a conductor, the locomotive engineer will perform the duties of the conductor.

The analysis of the tasks of operating crews, conducted by the railway, did not determine that job or equipment redesign were in order to provide adequate safety margins in one-person operations. Limited consideration was given to the radio communication, signal, or traffic control systems to ensure an equal or greater margin of safety in one-person operations.

1.11 Locomotive Engineer of Train 45

On 12 July 1996, the locomotive engineer of train 45 attended a company training session on one-person crew operations from 1330 until about 1630. He then went home and retired at about 2100. He awakened at 0035 on 13 July and was called for 0130. He reported for work and departed the terminal at about 0215, arriving at Mai at about 0650. He booked off at 0920 and went to bed between 1000 and 1100, sleeping until about 1400. He was called for 1630, operated a train northward to Carol Lake and booked off at 2240 on 13 July 1996. He spent the night in quarters rented by the company in Labrador City, retiring at about 2330. He arose at 0550 and went to work for 0620. The collision occurred at about 1045 on 14 July 1996.

1.12 Train Crew Management on QNS&L

Operating crews were assigned work on the basis of first-in first-out. A crew clerk maintains a board listing all employees available for work. An employee who books rest is not available until the rest period has terminated. QNS&L operates between iron mines located in the Wabush/Labrador City area and Sept-Îles. Typically, a crew operates from Sept-Îles to Mai, going off duty at Mai. The railway maintains a bunkhouse at Mai complete with a kitchen and cook on duty 24 hours a day and independent sleeping quarters for train crews and other railway personnel. After the required time off duty has elapsed, a crew will be assigned to take a train further north to Carol Lake, near Labrador City. At Carol Lake, a crew typically goes off duty again. Once their rest has elapsed, they are eligible to be assigned to take a train south to Mai. After off-duty time has elapsed at Mai, a crew will depart Mai destined to Sept-Îles. The rotation typically takes about three days. The trains do not operate on a precise schedule and are frequently subject to delays. Crews are therefore subject to irregular hours and accurate prediction of times on and off duty is often impossible.

The bunkhouse facility at Mai has two sleeping wings designated for train crews, both of which have recently been renovated. The rooms in the sleeping wing are approximately 10 feet by 10 feet. Each room is equipped with a single bed, a desk, a telephone and a chair. Window shutters are provided to block out most of the light from the outside. The heavy wooden doors were assessed as reasonably effective at muffling sound from the outside hallway. The facility is operated by an independent contractor.

At Wabush, crews stay at a local hotel. The rooms are standard hotel rooms with bed, television, telephone and separate washroom. There is a restaurant in the hotel.

1.13 Fatigue Countermeasures

Individuals and organizations challenged by irregular work schedules can apply a number of fatigue countermeasures to help workers maintain alertness. Countermeasures available can include lifestyle adjustments, work schedule adjustments, sleep hygiene, strategic napping and careful use of caffeine. Judicious use of such countermeasures requires a commitment by both the workers and the organization and a level of awareness of the hazard posed by fatigue.

Although the railway studied the issue of operator fatigue prior to implementation, railway operating officers questioned on fatigue and fatigue countermeasures were unaware of some basic physiological and behavioural factors relating to fatigue and were not well informed on countermeasures or on how they could be successfully implemented. They did not know that most people are very poor judges of their own levels of fatigue.

The recently negotiated collective agreement between the railway and the operating employees union, the UTU, included a 20-minute napping clause. This clause did not include details of how an employee would be awakened if he fell into a deep sleep. It stipulated that employees could only exercise their right to take a nap between the 10th and 12th hour on duty and only after the train had cleared the main track, hand brakes had been applied, an emergency backup device had been connected to the air hose on the front of the locomotive and secured to the rail. The employees would then be able to sit in their seat and nap for 20 minutes. The napping countermeasure had been instituted without arrangements to provide a cot so an employee could assume a horizontal position for napping, without providing a means of blocking out light such as the type of light-excluding eye covering used by passengers in commercial air travel and no establishment of a "quiet" radio channel that the locomotive radio could be placed on to avoid distraction while napping.

1.14 Situational Awareness and Decision Making

When making and implementing plans to move and control a train, the success of the locomotive engineer's decisions and actions will greatly depend upon an accurate assessment and understanding of the situation over time, and an ability to select appropriate courses of action based on that situational awareness. Situational awareness does not happen instantaneously, especially under dynamic operational conditions, but develops on three different levels.Footnote 3 First, a person has to perceive the situational elements from information displays, communications, or other references. Then, this information must be integrated into an overall understanding of the situation by using past experience and knowledge of how the system works. Finally, the person projects the information into the future to make and modify plans as tasks are completed or delayed as new developments arise.

In general, it can be expected that poor or unsuccessful operator performances will occur if there are problems at any one of these situational awareness levels,Footnote 4 i.e., although an optimum level of situational awareness cannot guarantee a successful performance, it can increase the probability of success. These problems could involve: a) the development of an incomplete or inaccurate situational awareness due to a failure to perceive certain information; b) the selection of an incorrect action for a given diagnosed situation due to a lack of knowledge or incorrect assessment; or c) a person's inability to carry out the correct action.

In the conventional multi-person crew operation, the minimum team consists of a locomotive engineer and a conductor, who work together and are both responsible for the safe and effective operation of the train movement. Their interactions, in terms of the identification and assessment of informational cues, the formulation of plans based on those cues, and the implementation and monitoring of their plans, create a line of defence which guards against the types of problems noted above. Through communication and cooperation, their partnership can promote team situational awareness and result in a greater opportunity for a successful performance. Shifting from conventional operation to locomotive-engineer-only operation will result in a reduction of situational awareness unless there are compensating factors implemented.

1.15 QNS&L Supervision and Training

Locomotive engineers were supervised by three road foremen. From time to time, the supervisors would ride in the cab with operating crews to check proficiency and adherence to rules. There were no formal standards for frequency or content of these observations; however, the railway has indicated that there was a minimum requirement that crews be ridden with at least once annually.

Reportedly, a locomotive engineer could work for several years without being monitored by a supervisor.

All training for both operating crews and RTCs, except rules training, was by on-the-job training. There were otherwise no formal training plans or standards. Rules training for locomotive engineers was done in accordance with regulatory requirements for initial qualification and re-qualification. On-the-job training can be an effective method of acquiring skills, but without training plans and standards, there is no way of ensuring exposure to and mastery of all the necessary knowledge and skills.

The radio communication between the locomotive engineer of train 45 and the RTC concerning the location of train 475 demonstrated inconsistent adherence to some regulatory requirements for content and precision of radio communication between RTCs and operating crews.

CROR Rule 126 states in part:

In addition to the restrictions in Rules 14 and 602, radio must not be used to;

(ii) give information which may influence a crew to consider that speed restrictions are diminished.

For instance, some RTCs tell operating crews about operational situations, such as stopped trains ahead, while others do not.

Regulatory requirements designed to ensure that critical information transmitted by radio is repeated by the receiving employee for accuracy were not consistently followed in this case. CROR Rule 123(c) states:

When verbal instructions or information pertaining to a train or engine movement are received by radio, such information must be repeated to the sender.

When the RTC informed the locomotive engineer of train 45 of the location of train 475, the transmission was not repeated back to the RTC. Rather, a form of positive acknowledgment was used.

1.16 Organizational Change

In a large organization, a valid job description is a vital management tool. A job description is produced from job analysis and describes the tasks to be performed and the working conditions of a job. "If thoroughly and completely done, job analysis provides a deeper understanding of individual jobs and their behavioural requirements and, therefore, creates a firm basis on which to make job related decisions."Footnote 5 The value of job analysis has been affirmed by safety authorities:

There is enormous pressure to reduce costs while at the same time improving quality. In addition, humanitarian and liability concerns require greater levels of safety, both for those who do the work as well as for the customer or client. The single most useful tool to meet these objectives is systematically analyze the work which is done and to establish appropriate procedures or practices to ensure that it is consistently done the proper way.Footnote 6

1.17 Undesired Emergency Brake Applications

An undesired emergency brake application (UDE), or "kicker" as it is commonly known within the railway industry, is a phenomenon that occurs after a service brake application has been initiated at the automatic brake valve. Sometime after the brake pipe pressure begins to reduce at a service rate, usually within several seconds, an individual air brake control valve located somewhere in the train reacts abnormally to the service rate of reduction, resulting in an UDE on that particular car. Once one control valve has sensed an emergency reduction rate in brake pipe pressure, it propagates a further brake pipe pressure reduction throughout the train at an emergency rate, resulting in a full train emergency brake application. The North American railway industry has recognized UDEs as a problem and, over the last decade, a number of studies have been conducted. UDEs have been linked to a condition of over-sensitivity in certain air brake control valves.

QNS&L had recognized that they had a problem with UDEs on their iron ore trains. The railway, after having conducted their own testing, hired an independent consultant to address UDEs. The consultant attributed the QNS&L incidents of UDEs to the same over-sensitive control valves that had been identified within the industry at large. The consultant further linked the problem to the combination of several different control valves within the consist of QNS&L iron ore trains. A series of recommendations was provided by the consultant to QNS&L to reduce the incidence of UDEs. QNS&L had begun to implement the recommended changes and the incidents of UDEs had begun to decline.

The locomotive engineer of train 45 indicated that he believed that train 475 was approaching Mai for the station stop. He indicated that it had been common for southward iron ore trains to experience UDEs when stopping at Mai to change crews. Normally, on a southward train, the automatic brake would be applied closer to Mai than was the case with train 475; however, in this case, train 475 had been signalled to stop north of the north siding switch, a distance of two miles north of the station.

2.0 Analysis

2.1 Introduction

Neither the operation of train 475 nor the role of the RTC relative to the operation of train 475 was causal to the accident. The operation of train 45 did not conform to the signal indication and the locomotive engineer was operating his train at a speed that did not permit him to stop short of the stationary equipment. The analysis focuses on the sequence of events leading up to the collision, the factors that may have influenced the decision-making process of the locomotive engineer of train 45, and the absence of a comprehensive systems approach to the major operational change to locomotive-engineer-only train operation on QNS&L.

2.2 Consideration of the Facts

2.2.1 The Collision

The locomotive engineer of train 45 was aware of the difficulties the railway had been experiencing with UDEs. When the RTC informed him that a train was stopped in emergency north of the north siding switch at Mai, he did not find the situation unusual and concluded, on the basis of his experience, that the train was stopped further south than it actually was. This was not consistent with what the RTC had said, but in the mind of the locomotive engineer, that is what the RTC meant. The locomotive engineer's assessment of the situation was inaccurate. He did not repeat the RTC's transmission regarding the location of train 475 to the RTC nor did the RTC request a repeat, so the transmission was not verified by either of the communicating parties. There was no one else in the locomotive cab or otherwise privy to the locomotive engineer's resultant actions who could have intervened to correct his perception. Elimination of the requirement for other employees to be in the locomotive cab removed a line of defence against the type of perception error that occurred in this instance.

Had the RTC not informed the locomotive engineer of train 45 that a train was stopped in emergency near Mai, the locomotive engineer would have had only signals 134.2 and 132.6 to provide information about conditions on the track ahead. The clear to stop signal (Signal 134.2) and restricting signal (Signal 132.6) provided little information for the locomotive engineer to use in updating his situational awareness or mental model of the situation; however, these indications alone would have prescribed the action to be taken. The availability of additional, although misinterpreted, information led the locomotive engineer to believe that it was safe to maintain a higher rate of speed than prescribed by the signal indications. In a one-person environment, clear, unambiguous communication is critical because the sole operator has no backup in case a piece of information is missed, unclear or misinterpreted. The dissemination of all available, pertinent information to the appropriate persons is an issue that has been recognized in the air and marine modes of transportation in the form of Crew Resource Management and Bridge Resource Management respectively. Essential to the success of these programs are the establishment of and adherence to specified methods of transmission and verification. When these processes are not in place, there is a greater risk that a piece of information could be misinterpreted. While the RTC's intentions in advising the locomotive engineer of the location of train 475 were sound, the methods employed in verification of that information were not. Although the railway has established verification procedures when information is transmitted by radio or telephone (that were not adhered to in this instance), there is no formal Cab Resource Management program.

Regardless of the locomotive engineer's interpretation of the RTC's radio transmission, CROR Rule 426 (Restricting Signal) clearly required the locomotive engineer to reduce speed to a maximum of 15 mph on passing Signal 132.6. The locomotive engineer did not do this. He believed that, since he knew where the train ahead was stopped, he could continue at a higher speed, and stop as required. He was engaged in a series of locomotive control adjustments approaching the point of impact. As he rounded the curve and the rear end of train 475 came into view, he acted almost instantaneously in placing his train brakes in emergency. This action slowed his train by approximately 10 mph and undoubtedly reduced the severity of the impact.

The empty hopper car on the tail end of train 475, being much lighter than the loaded cars ahead, lifted at impact and caused most of the damage to the lead locomotive of train 45, locomotive 320. The raised empty car sheared off the short hood and cab of the locomotive, except for the locomotive engineer's control stand and seat and the bottom half of the right-hand side wall. The area of the locomotive engineer's workstation was relatively well preserved. The locomotive engineer elected not to detrain despite the fact that some 13 seconds elapsed between the emergency brake application and impact.

Management's responsibilities include an obligation to provide training and supervision which encourage adherence to procedures and discourage short cuts. QNS&L road foremen were not required to meet any formal standards for frequency or content of proficiency check rides with operating crews; however, there was an unwritten philosophy is this regard. While it is not possible to state whether maintaining a higher-than-authorized speed is a frequent or rare event, the need for training and supervisory practices to ensure adherence to rules is even more critical in a one-person operation than in a team operation because the opportunity for checks for accuracy of perception and interpretation of information and cues is removed.

2.2.2 Locomotive-Engineer-Only Train Operation

Locomotive-engineer-only train operation represents a fundamental change in the Canadian railway industry. Although it is true that there are scattered examples of locomotive-engineer-only commuter and passenger train operations, QNS&L is the first long-haul freight railway in Canada to attempt locomotive-engineer-only train operations. Most trains in Canada are operated by two- or three-person crews. The locomotive engineer operates the locomotive. The conductor has overall responsibility for the train, and the conductor and the third crew member perform off-train work, such as coupling and uncoupling cars and lining switches. In conventional multi-person crew operation, the locomotive engineer does not work in isolation. There is at least a second or perhaps even a third person beside the locomotive engineer tasked to identify initially and then confirm and assess perceptual information, formulate and assess plans based on such information, and subsequently implement and monitor these plans. Through these interactions, they are able to help develop and maintain each other's situational awareness. In QNS&L's locomotive-engineer-only operations, a line of defence was removed without compensatory safeguards in terms of equipment, procedures or training set in place.

Several agreed-upon contractual provisions actually work against compensating for the removal of the other crew members from the operating cab of the train: reducing the amount of rest a locomotive engineer can take at his "away-from-home terminal" from nine hours to seven hours, and restricting locomotive engineers from obtaining relief en route until they have been on duty for 12 hours as opposed to 10 hours. These changes point to a lack of understanding of the fundamental effects the change to locomotive-engineer-only operation was likely going to have. Social interaction between people is a proven countermeasure against fatigue. Yet, the fact that locomotive-engineer-only train operation greatly reduces the opportunity for the locomotive engineer to interact socially is not recognized or compensated for. Napping is a recognized countermeasure against fatigue and was used as one of the test countermeasures in the CANALERT '95 study. Representatives from the QNS&L attended a presentation on the CANALERT '95 study from which they incorporated their napping philosophy. In order for napping to be effective, the CANALERT '95 study included several essential preparatory steps. A mattress that could be rolled out on the locomotive floor was provided to enable the locomotive engineer to assume an appropriate resting position. Light blocking visors were provided to be worn by the locomotive engineers while napping. A designated radio channel was established to eliminate disturbing noise and to enable RTCs to wake the locomotive engineers at the completion of the nap. QNS&L did not include these preparatory steps.

Each of these points indicate that QNS&L instituted a major operational change without a comprehensive analysis of the effects that change was going to have on its operation. In order to achieve the railway's goal safely, it was necessary to obtain a thorough understanding of the current job functions, predict the ramifications of the operational change to the entire operating system, and make whatever changes were necessary to ensure that employees could perform the job safely under the new operating conditions.

Presentations given by QNS&L to Transport Canada gave an advance look at the approach QNS&L was going to take in achieving locomotive-engineer-only train operations. Despite the opportunity this presented for Transport Canada to enhance the railway's approach to a major operational change that would clearly have safety implications, constructive criticisms offered were limited. Transport Canada's recollection of the nature and scope of comments offered differed greatly from the railway's recollection of those comments; however, regardless of their content, in the end, they had little positive effect.

Specific elements of CROR Rule 106 that refer to the locomotive engineer assuming the role of the conductor were interpreted by the railway as appropriate regulatory provisions to operate locomotive-engineer-only trains. These provisions empower the locomotive engineer to make necessary decisions and take necessary action concerning the train when the conductor is temporarily indisposed. Many operating rules are purposely vague and non-prescriptive to allow responsible application in a wide range of circumstances. QNS&L used the flexibility built into this rule to suit its needs when this was clearly not the intent of the subject provision.

In the 48 hours before the accident, the locomotive engineer had obtained about 13 hours of sleep, at least 3 of which were between 1000 and 1400 on 13 July. Sleep obtained during this time period is often of poor quality and less likely to be restorative. Human sleep needs over a period of 48 hours would normally be satisfied by between 15 and 17 hours of sleep obtained in two overnight episodes. Although the numerous adjustments to locomotive controls leading up to the collision would seem to indicate that the locomotive engineer was alert, the role that fatigue may have played in his perception of information and the subsequent decision-making process cannot be dismissed.

The operation of a train with one occupant in the operating cab is not inherently unsafe. There are many examples around the world where trains are operated safely with one occupant in the cab. There is, however, cause for concern as to the extent to which QNS&L compensated for the safety implications of a crew reduction to one person in the operating cab.

3.0 Findings

- Neither the operation of train 475 nor the role of the RTC relative to the operation of train 475 was causal to the accident.

- The locomotive engineer of train 45 did not operate his train in compliance with the governing signal indication.

- A restricting signal was disregarded and train 45 was operated at such a speed that the locomotive engineer was unable to stop short of the rear end of train 475 in the available sight-lines.

- There was no other railway employee in a position to question the actions taken by the locomotive engineer of train 45 in operating his train at an excessive rate of speed.

- There was no means of intervention associated with the CTC system capable of stopping or slowing a train. Furthermore, there was no passive warning system associated with CTC that would alert a locomotive engineer of the train's proximity to points of restriction or rolling stock.

- The locomotive engineer of train 45 was predisposed to thinking that train 475 was further south than it actually was due to his belief that train 475 had experienced an undesired emergency brake application while preparing to stop for a crew change at Mai.

- The possibility that fatigue may have contributed to the locomotive engineer's decision not to comply with the governing signal indication cannot be ignored.

- Established verification procedures were not used to ensure that there was a clear understanding between the locomotive engineer of train 45 and the RTC as to the location of train 475, resulting from their conversation before the collision.

- There is currently no established crew resource management program in use on the railway that would ensure that all persons involved are aware of the most up-to-date, accurate information concerning the movement of trains and engines.

- Locomotive-engineer-only train operations were implemented on the QNS&L without the benefit of a comprehensive analysis of the impact a further crew reduction would have on their operation and without the introduction of any countermeasures that would ensure an equivalent level of safety.

- The provisions of CROR Rule 106 that require the locomotive engineer to assume the responsibility of the conductor in his temporary absence were utilized by QNS&L in support of locomotive-engineer-only train operations.

- Transport Canada's response to QNS&L's proposal to operate locomotive-engineer-only trains was interpreted as approval to begin locomotive-engineer-only train operations by QNS&L.

- QNS&L was not aware of Transport Canada's expectation that they provide details of their plans to operate locomotive-engineer-only train after the completion of union negotiations.

- There was no formal program specifying requirements for the frequency and methodology of supervisory activities for operating employees on QNS&L.

- According to locomotive engineers interviewed, it was not generally known by supervisors that management expected them to meet on a regular basis and accompany each locomotive engineer on at least one trip a year.

3.1 Causes and contributing factors

The collision occurred because the moving train was operated past a governing restrictive signal, at a speed at which the locomotive engineer was unable to stop short of the stationary equipment. The implementation of the major operational change to locomotive-engineer-only train operation without a comprehensive analysis of its impact and without the implementation of effective compensatory safety measures contributed to this occurrence.

4.0 Safety Action

4.1 Action Taken

Shortly after this collision, Transport Canada (TC) restricted QNS&L from operating any trains with a locomotive engineer only until QNS&L had received appropriate exemptions from the CROR. The railway requested exemptions from specific operating rules on 26 July 1996 to re-establish locomotive-engineer-only train operations. In its letter of reply on 26 August 1996, TC stipulated 13 specific safety-related conditions that had to be met before the exemptions could be granted. The railway met the conditions and the appropriate exemptions were granted on 24 April 1997. Locomotive-engineer-only train operations recommenced on 17 July 1997. Furthermore, a working group was formed comprising headquarters and regional TC staff, representatives of QNS&L and the UTU. As a result of group discussions, consensus was met on proposed changes to the current operating practices that would ensure that locomotive-engineer-only train operations would be as safe as an equivalent multi-employee operation.

There were more than 65 improvements outlined by the working group; some of the more significant ones follow:Footnote 7

a Proximity Detection Device (PDD) will be installed and operational on all lead locomotives, track units and on-track vehicles operating on the main track between Sept-Îles and Wabush Lake Junction. The only exception will be in large production gangs where only the two machines or pieces of equipment at the extreme ends of the gang need be so equipped;

the QNS&L must ensure that the passenger train crews are assigned and scheduled, and that all through freight trains are scheduled from Sept-Îles;

no switching is to be carried out unless a second qualified employee assists;

to facilitate napping, locomotives will be equipped with a napping radio channel, blindfolds, timers for locomotive engineers, and reclining seats;

locomotive engineers will receive 120 to 130 hours of training in train operations, simulator training, first-aid training, fire extinguisher training, proper interpretation and application of those rules affected by locomotive-engineer-only train operation, the proper use of the PDD system, and training in emergency procedures applicable to locomotive-engineer-only operations;

rail traffic controllers will receive similar training as locomotive engineers pertaining to locomotive-engineer-only operation. TC has implemented a system to monitor the training program;

there will be increased supervision of locomotive engineers;

locomotive engineers must transmit on the standby channel of the train radio, in a clear and audible manner, the indication by name of each fixed signal they are required to identify;

- QNS&L will implement and maintain a system to record data related to the performance indicators and tracking mechanisms as laid out in the QNS&L (undated) paper presented to the Railway Safety Directorate, Transport Canada, on 25 November 1996.

On 03 September 1996, TC advised the Railway Association of Canada (RAC), in writing, that the RAC was expected to develop a rule or rules, in consultation with the industry, that would govern one-person train operations. TC has recently received a submission from the RAC but the matter is still being reviewed. Meanwhile, TC has not received any further requests from an exemption from the existing rules.

This report concludes the Transportation Safety Board's investigation into this occurrence. Consequently, the Board, consisting of Chairperson Benoît Bouchard, and members Maurice Harquail, Charles Simpson and W.A. Tadros, authorized the release of this report on .

Appendices

Appendix A— Transport Canada's Documentation on QNS&L's

Request for Exemption to Regulations

QNS&L Commitments to be Completed Prior to Implementation of One Employee Train Operations

-

A.1The QNS&L will implement and maintain a system to record data related to the performance indicators and tracking mechanisms as laid out in the QNS&L (undated) paper presented to the Railway Safety Directorate, Transport Canada on November 25/96.

-

A.2The QNS&L will prepare summary reports in several areas, including, but not limited to, accidents and incidents, equipment defects, rule violations, human resources, and emergency calls. The summary reports will be provided to the Railway Safety Directorate, Transport Canada on a monthly basis, except where the frequency is otherwise defined in specific commitment areas. The requirement for providing reports and the frequency with which they will be provided will be re-evaluated after a twelve month period by the Railway Safety Directorate, Transport Canada in conjunction with the QNS&L.

-

A.3The QNS&L will ensure that the maximum hours on duty for locomotive engineers does not exceed twelve consecutive hours from the on duty time. Such employees, after having reached their 12th hour on duty, will be relieved of all operational duties and will be given mandatory rest on arrival at their final destination (intended destination when the train was ordered) or the first location where accommodations are available. Employees may be deadheaded prior to or subsequent to the expiration of the twelfth (12th) hour.

-

A.4The QNS&L will ensure that a minimum rest period of five hours, including a one hour call period, will be mandatory at Mai and Labrador City. A minimum rest period of twelve hours, including a two hour call period, will be mandatory on arrival at Sept-Iles. These restrictions are supplemental to the requirements of existing federal mandatory rest regulations.

-

A.5The QNS&L will ensure that trains operating from Sept-Iles to Schefferville or from Schefferville to Sept-Iles are crewed by two qualified locomotive engineers who will trade off as they deem necessary.

-

A.6The QNS&L will provide quarterly reports to the Railway Safety Directorate, Transport Canada showing trends in work hours. The requirement for providing reports and the frequency with which they will be provided will be re-evaluated after a twelve month period by the Railway Safety Directorate, Transport Canada in conjunction with the QNS&L.

-

A.7The QNS&L will adopt a clear definition of "emergency", a copy of which will be provided to the Railway Safety Directorate, Transport Canada. The definition will specify that contingencies which are not unusual in railway operations, such as winter weather or routine train and mine delays, still fall within the maximum twelve hours on duty.

-

A.8The QNS&L will ensure that passenger train crews are assigned and scheduled.

-

A.9The QNS&L will ensure that through freight trains are scheduled from Sept-Iles.

-

A.10The QNS&L will, in conjunction with Wabush mine management and to the extent possible, plan the estimated departure times of Wabush trains; it will not be less than the 24 hour forecast window which exists for IOC trains.

-

A.11The QNS&L will establish a system permitting employees to give advance notice of time off required so as to reduce the likelihood of employees booking leave on call. The crew calling system will be updated as soon as an employee books leave within the 24 hour forecast window, in order to reflect an accurate picture of probable call times for other employees.

-

A.12The QNS&L will ensure that locomotive engineers will not be turned north out of Mai after the third leg of the cycle unless unavoidable. If unavoidable, affected employees will be notified as soon as possible. On a monthly basis, and in conjunction with the Occupational Safety and Health (OSH) Committee, the company will monitor the frequency with which this occurs and why, and a quarterly report will be provided to the Railway Safety Directorate, Transport Canada. The requirement for providing reports and the frequency with which they will be provided will be re-evaluated after a twelve month period by the Railway Safety Directorate, Transport Canada in conjunction with the QNS&L.

-

A.13The QNS&L will, in conjunction with the OSH Committee, develop and implement job briefing procedures.

-

A.14The QNS&L will ensure that the task checklist for one employee train operations, developed by the QNS&L in conjunction with the OSH Committee, is available to all locomotive engineers when on duty.

-

A.15The QNS&L will ensure that there is no switching carried out unless a second qualified employee assists.

-

A.16The QNS&L will ensure that negotiated alertness breaks are permitted after the third hour on duty, and then at 4 hour intervals unless an opportunity break has been taken in the interim, in which case, the next negotiated break would be permissible 4 hours after the previous break, regardless of whether it was an opportunity or negotiated break.

-

A.17The QNS&L will ensure that alertness breaks are 20 minutes undisturbed.

-

A.18The QNS&L will ensure that alertness breaks are not permitted between miles 58 and 74 on the Wacouna Subdivision.

-

A.19The QNS&L will ensure that alertness break periods are considered as on-duty time in the application of the 12 hour maximum on duty time.

-

A.20The QNS&L will provide clear instructions to Rail Traffic Controllers (RTC) to ensure that they are aware of and will comply with alertness break procedures.

-

A.21The QNS&L will, in conjunction with the OSH Committee, conduct a joint evaluation of locomotive seats, specifically the DASH-8 locomotive seats, in order to ensure that at least one seat in a locomotive cab is adequate for napping.

-

A.22The QNS&L will provide the following, to facilitate napping:

- a napping radio channel;

- blindfolds;

- timers for locomotive engineers; and

- reclining seats on locomotives.

-

A.23The QNS&L, in order to facilitate alertness, will provide headphones to locomotive engineers and cassette players on locomotives.

-

A.24The QNS&L will ensure that there are functioning ditch lights on lead locomotives of trains operating with only one employee.

-

A.25The QNS&L will issue instructions prohibiting:

- movements with the controlling locomotive oriented with long hood leading; and

- operation of a locomotive consist from a cab other than that on the leading end of the movement, unless a second CROR qualified employee accompanies the movement and is in position to ensure that the route to be used is clear.

-

A.26The QNS&L will conduct a joint evaluation with the OSH Committee to determine where the Proximity Detection Device (PDD) equipment can be installed in the locomotive cab so as not to:

- impede the locomotive engineer's field of vision; or

- cause discomfort to the locomotive engineer when required to operate such equipment.

-

A.27The QNS&L will issue instructions to ensure that, prior to exiting the locomotive cab, the locomotive engineer must perform a portable radio communication test; whether or not the locomotive engineer is descending the locomotive. Where there is a failure to obtain communication with the RTC, the locomotive engineer must contact the RTC using the mobile radio, advising the RTC that a portable radio test is about to be performed outside the locomotive cab. If the locomotive engineer is unable to contact the RTC using the portable radio, the locomotive engineer must not leave the locomotive. RTCs will record locations where communication via the portable is not possible.

-

A.28The QNS&L will sample compliance with radio-related rules and instructions on a monthly basis. A record of the findings and remedial action taken, will be maintained by the QNS&L and will be available, on request, to Transport Canada.

-

A.29The QNS&L, in conjunction with the OSH Committee will, once the Northernland Subdivision radio tower is functioning, conduct a survey between Sept-Iles and Wabush Lake Junction to highlight where dead spots or problem areas exist. These areas are to be identified in a document to be distributed to all operating personnel. If problem areas are identified additional to those previously identified at miles 24 and 67 of the Wacouna Subdivision, radio repeaters will be installed on locomotives.

-

A.30The QNS&L will provide employees with the instruction package which has been developed by the QNS&L on the proper handling and use of portable radios and battery chargers.

-

A.31The QNS&L will provide locomotive engineers with radio holsters with belt attached in order to ensure that the portable radio remains with the employee at all times when the employee leaves the locomotive cab.

-

A.32The QNS&L will ensure lead locomotives are equipped with a functioning battery charger and spare battery for the portable radio.

-

A.33The QNS&L will ensure that there is a functioning mechanical emergency device (MED) available on the engine, otherwise the locomotive engineer will not be permitted to detrain en route.

-

A.34The QNS&L will issue clear written procedures to locomotive engineers on the proper use of the MED, including instructions on how to handle situations where the device is rendered inoperative.

-

A.35The QNS&L will, in conjunction with the OSH Committee, review and revise the existing emergency procedures in order to:

- decrease the delay in first aid attendance (using the simulation of November 27, 1996 as a reference);

- establish clear instructions for RTCs including defining at what point the RTC must implement emergency response procedures, when:

- attempts by the RTC to communicate with a locomotive engineer who has left the locomotive cab are unsuccessful; and

- a train is inexplicably delayed in a block and attempts by the RTC to contact the locomotive engineer are unsuccessful.

-

A.36The QNS&L will ensure that the 30 minute interval for communication with the RTC when a locomotive engineer leaves the locomotive cab will be reduced to 15 minutes for winter operations, with winter operations defined as November 1 to March 31.

-

A.37The QNS&L will provide RTCs with timers to be used by RTCs to track the intervals between communications from a locomotive engineer who has had to leave the locomotive cab.

-

A.38The QNS&L will ensure that when QNS&L employees are first responders to an emergency situation on the line, they are equipped with at least one portable radio capable of toning in the RTC.

-

A.39The QNS&L will provide first aid kits combined with survival kits to all locomotive engineers when they report for duty. Locomotive engineers will be required to carry these with them when they detrain from the locomotive to attend to their train.

-

A.40The QNS&L will equip locomotives and those track units suitable for transporting injured employees, with spinal boards.

-

A.41The QNS&L will provide a revised training plan, detailing delivery of training initiatives related to one employee train operations, to the Railway Safety Directorate, Transport Canada.

-

A.42The QNS&L will ensure that all locomotive engineers, who remain with the QNS&L after the implementation of one employee train operations, have received the following training:

- 120-130 hours of training, that includes:

- technical train operations training;

- practical training on a simulator;

- basic first-aid training;

- training in the use and handling of fire extinguishers;

- training in the proper interpretation and application of those operating instructions, rules and procedures affected by one employee train operations; and

- lifestyle training;

- a refresher training session which will include instruction on any rules exemptions that may be approved to permit one employee train operations;

- training in the proper use of a PDD system; and

- training in emergency procedures applicable to one employee train operations.

- 120-130 hours of training, that includes:

-

A.43The QNS&L will ensure that employees who are being newly qualified as locomotive engineers, receive on-job training with an experienced locomotive engineer.

-

A.44The QNS&L will ensure that new locomotive engineer candidates have passed a practical, on-job examination given by a Road Foreman of Engines, before they are qualified for the job category of locomotive engineer.

-

A.45The QNS&L will ensure that there are feedback mechanisms in place to facilitate the company's ability to identify and respond appropriately to the training needs of employees, including:

- written feedback from employees after each phase of training;

- recorded observations made by supervisory personnel, including the Rules Instructor, during road trips with employees; and

- personal contact between a Road Foreman of Engines and each employee at least once a month, wherein the employee has the opportunity to discuss problems or concerns regarding train operations.

-

A.46The QNS&L will ensure that there are non-threatening systems in place to support ongoing training initiatives, including:

- a means, both direct and indirect, for employees to consult with the Rules Instructor; and

- an Employee Assistance Program to support lifestyle training.

-

A.47The QNS&L will provide RTCs with an information package on one employee train operations.

-

A.48The QNS&L will ensure that all RTCs have received the following training:

- refresher training in the proper interpretation and application of those operating instructions, rules and procedures affected by one employee train operations;

- training in any rules exemptions granted to permit one employee train operations; and

- training in emergency procedures applicable to one employee train operations.

-

A.49The QNS&L will ensure that other employees (i.e. other than locomotive engineers and RTCs; supervisory personnel included) who may be required in unusual or emergency circumstances to assist a one employee train, are provided with the necessary training, including training in radio and emergency response procedures, to enable them to do so safely and effectively.

-

A.50The QNS&L will provide the Railway Safety Directorate, Transport Canada with the following information:

- confirmation that there is a system in place to track ongoing training initiatives for those employees involved either directly or indirectly with one employee train operations; and

- confirmation of the date that each locomotive engineer successfully completes all training required for one employee train operations.

-

A.51The QNS&L will maintain a program for increased supervision of locomotive engineers comparable to that which was implemented in November 1996. The program will include, but is not limited to, the following:

- Each locomotive engineer will be accompanied by a Road Foreman of Engines on at least one trip every 8 months.

- At least one general assessment of an event recorder download of a trip per locomotive engineer will be conducted by a Road Foreman of Engines every 2 months.

- A Road Foreman of Engines will personally contact each locomotive engineer on a monthly basis to discuss problems or concerns of the employee's choosing, related to train operations.

- Event recorder download analyses will be conducted on a monthly basis by the Road Foremen of Engines based on indicators determined by the company to be meaningful for assessing operating performance.

- A system is in place to track the activities noted in a) through d) above and follow-up action taken with employees.

-

A.52The QNS&L will ensure that each newly qualified locomotive engineer will be accompanied by a Road Foreman of Engines (or another experienced, qualified locomotive engineer) for their first several trips between miles 58 and 74, Wacouna Subdivision because of the train handling peculiarities of this stretch of track.

-

A.53The QNS&L will not revert to locotrol operation on one employee trains.

-

A.54The QNS&L will limit train length to a maximum of 168 cars on one employee trains.

-

A.55The QNS&L will ensure that the installation of the PDD system is complete and the system is operational.

-

A.56The QNS&L will ensure that all lead locomotives, track units and on-track vehicles operating on the main track between Sept-Iles and Wabush Lake Junction, are equipped with a functioning PDD system. The only exception will be in large production gangs where only the two machines or pieces of equipment at the extreme ends of the gang need be so equipped.

-

A.57The QNS&L will ensure that in the event of an en route PDD failure, the locomotive engineer, or the track unit or on-track vehicle operator will immediately advise the RTC and will then proceed to the nearest available siding in the direction of movement and there await repair or replacement of the PDD or the assistance of a second CROR qualified employee for the remainder of the trip or until an operational PDD is made available. In addition, the QNS&L will ensure full protection is provided for and against any movement that has developed a PDD failure en route; this considering that a PDD component failure on one movement may render that train, engine, track unit or on-track vehicle invisible to the functioning PDD equipment of another movement.

-

A.58The QNS&L will ensure that lead locomotives are equipped with functioning, tamper-proof Reset Safety Control devices (RSC) which are set to time out at appropriate intervals. In the event of an en route RSC failure, the locomotive engineer will immediately advise the RTC and will then proceed to the nearest available siding in the direction of movement and there await repair or replacement of the RSC or the assistance of a second CROR qualified employee for the remainder of the trip or until an operational RSC is made available on the lead locomotive.

-

A.59The QNS&L will re-implement the requirement for pull-by inspections at Mai when crews change off on connection.

-

A.60The QNS&L will review existing selection criteria for newly hired employees who are to be considered for the job category of locomotive engineer in recognition of the changed demands on locomotive engineers working in one employee train operations.

-

A.61The QNS&L will ensure that locomotive engineers will transmit on the standby channel of the train radio, in a clear and audible manner, the indication by name of each fixed signal they are required to identify.

-

A.62The QNS&L will ensure that locomotive engineers will, prior to commencing movement, perform a visual inspection of both sides of their train. Such inspection may be conducted from the locomotive cab. In addition, at Sept-Iles, Mai, Carol Lake and other locations where qualified employees are available, locomotive engineers will not commence movement until the proper signal has been received from a certified car inspector or other qualified employee.

-

A.63The QNS&L will ensure that in the application of the exemption to CROR Rule 102(a)(ii), locomotive engineers will provide flag protection toward the front of the train. Rear protection will be provided by the RTC, who will not allow one train to overtake another from the rear, if the train being overtaken is moving in a siding. The RTC will block the appropriate signals to the rear at stop, until the train in the siding has confirmed that it has stopped and that it will not resume movement until the train operating on the main track has passed.

-

A.64The QNS&L will ensure that locomotive engineers are relieved of the requirement to perform inspections of passing trains while on alertness breaks and only after notifying the RTC that an alertness break is being taken.

-

A.65The QNS&L will complete their program of upgrading their hot box detectors with state-of-the-art equipment. QNS&L Commitments which need not be Completed Prior to Commencement of One Employee Train Operations

QNS&L Commitments which need not be Completed Prior to Commencement of One Employee Train Operations

-

A.66The QNS&L will, in conjunction with the OSH Committee, continue the ongoing process of:

- identifying the critical tasks of the locomotive engineer in one employee train operations, particularly those tasks performed outside the locomotive cab;

- conducting a detailed analysis of the critical tasks; and

- identifying, with a view to mitigating, the risks for a locomotive engineer in one employee train operations performing tasks outside the locomotive cab.

-

A.67The QNS&L will provide locomotive engineers with the following training as part of ongoing training initiatives. In the case of item b) below, survival training will initially be given to locomotive engineers prior to November 1, 1997:

- training in Passenger Evacuation Procedures; and

- survival training, to be given by a subject matter expert.

-

A.68The QNS&L will arrange for an assessment of the medical fitness of locomotive engineers to be conducted commencing January 1997. The QNS&L will not require any employee to perform tasks that may be a hazard to the employee's health or safety.

-

A.69The QNS&L will, in conjunction with the OSH Committee, develop and implement criteria for working outside in cold weather. This initiative will be completed before November 1, 1997.

Appendix B— Glossary

- CROR

- Canadian Rail Operating Rules

- CTC

- Centralized Traffic Control System

- ETIS

- end-of-train information system

- IOC

- Iron Ore Company of Canada

- MED

- mechanical emergency device

- mph

- mile(s) per hour

- OSH

- Occupational Safety and Health

- PDD

- Proximity Detection Device

- QNS&L

- Quebec North Shore and Labrador Railway

- RAC

- Railway Association of Canada

- RSC

- Reset Safety Control

- RTC

- rail traffic controller

- TC

- Transport Canada

- TSB

- Transportation Safety Board of Canada

- UDE

- undesired emergency brake application

- UTC

- Coordinated Universal Time

- UTU

- United Transportation Union