Crossing collision

Canadian National Train L51141-23

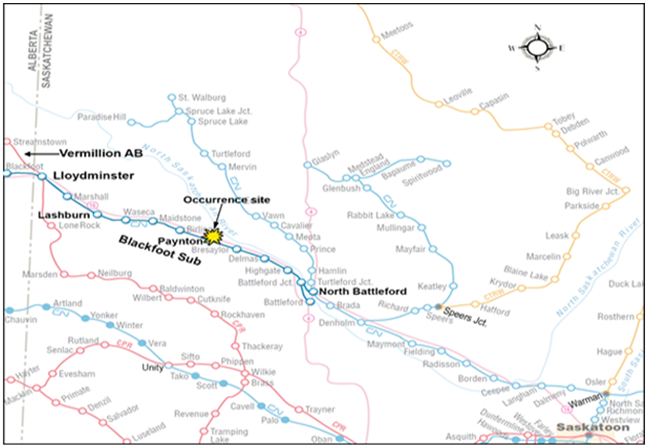

Mile 33.70, Blackfoot Subdivision

Paynton, Saskatchewan

The Transportation Safety Board of Canada (TSB) investigated this occurrence for the purpose of advancing transportation safety. It is not the function of the Board to assign fault or determine civil or criminal liability. This report is not created for use in the context of legal, disciplinary or other proceedings. See Ownership and use of content. Masculine pronouns and position titles may be used to signify all genders to comply with the Canadian Transportation Accident Investigation and Safety Board Act (S.C. 1989, c. 3).

Summary

On 24 January 2013 at 0856 Central Standard Time, eastbound Canadian National train L51141-23 struck a road grader that had stopped on the public grade crossing at Mile 33.70 of the Blackfoot Subdivision. As a result of the collision, the road grader was heavily damaged and the grader operator sustained fatal injuries. The train crew were not injured. Thelocomotive and 16 tank cars carrying dangerous goods derailed. Approximately 106,000 litres of crude oil was released from 4 cars.

Factual information

The accident

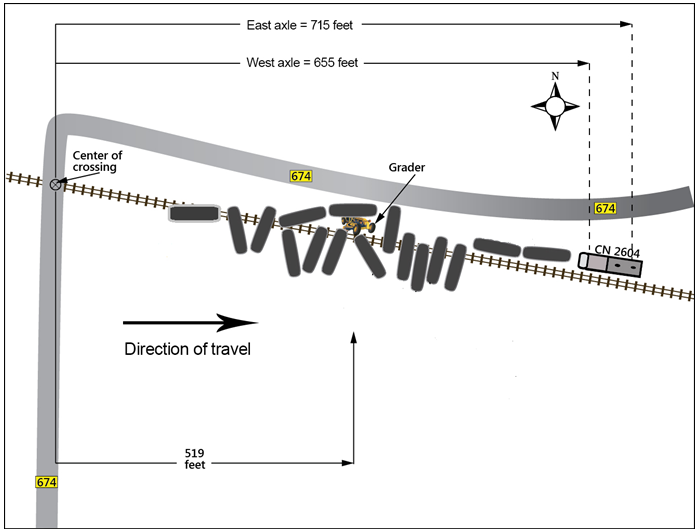

On 24 January 2013, at approximately 0856,Footnote 1 Canadian National (CN) train L51141-23 (the train) was traveling eastward on the Blackfoot Subdivision at about 37 mph with the throttle in traction position 8. Approaching the public grade crossing at Mile 33.70 in Paynton, Saskatchewan, the train crew saw a road grader back up onto the crossing (from the south to the north) and come to a stop (Figure 1). The road grader was being used to clear snow that had accumulated on Highway 674 after a snowfall the previous night.

As the train approached the crossing, the engine horn and bell were activated; several more horn soundings were initiated. The road grader continued to occupy the crossing. The throttle was then moved to idle and the train was placed into emergency.

Unable to stop in time, the train collided with the stationary road grader. The force of the collision propelled the road grader eastward for approximately 519 feet where it came to rest on the north side of the track. The grader operator sustained fatal injuries. The lead locomotive (CN 2604) continued east and derailed approximately 715 feet past the crossing. In addition, 16 loaded dangerous goods tank cars carrying petroleum crude oil (UN 1993) derailed (Figure 2). Four DOT Class 111 cars were breached and released 106 000 L of crude oil. The locomotive sustained damage to the long hood and running gear due to the collision and derailment. The crew was uninjured.

It was morning light conditions at the time of the occurrence. The temperature was -17°C and it was overcast. The visibility was good.

Crew and train information

The train crew consisted of a locomotive engineer, a conductor, and a trainman. The crew members were qualified for their respective positions and met fitness and rest standards. The train crew had previously operated over this territory. Originally called to work at the North Battleford Yard, the crew were reassigned to train L51141-23 when they reported for duty at 2215 (23 January 2013). The original crew for this train had reached the limits of their hours.

The train comprised 1 locomotive and 44 loaded dangerous goods tank cars. The train was about 2580 feet in length and weighed approximately 5670 tons. The tank cars had been picked up earlier at a crude oil loading facility in Lashburn, Saskatchewan. The train was en route back to North Battleford Yard. As there had been nowhere to turn the locomotive around (e.g., a wye) during the return trip, the locomotive was being operated in the long hood leading (i.e., reverse) orientation.

Mechanical inspection and repair records for the locomotive and the tank cars indicate that all equipment had been in serviceable condition prior to the accident. The train crew had given the train a number 1A airbrake testFootnote 2 before it departed Lashburn.

Blackfoot Subdivision and track information

The Blackfoot Subdivision commences at North Battleford, Saskatchewan, (Mile 0) and extends west to Vermilion, Alberta, (Mile 124.4) (Figure 1). The method of train control is the Occupancy Control System (OCS), as authorized by the Canadian Rail Operating Rules (CROR) and supervised by a rail traffic controller (RTC) located in Edmonton, Alberta.

The track in the area of the crossing was 100 lb. Dominion rail manufactured in 1959. The track was jointed rail with 39 foot sections. The rail was held in place by 11 inch double shoulder tie plates. The rail was secured to a mix of hardwood and softwood ties using 2 spikes per plate (opposite holes). The ballast was crushed stone.

In the vicinity of the crossing, the track was tangent with a slight ascending grade to the east. The authorized timetable speed at this location was 40 mph. The track was Class 3 track in accordance with Transport Canada’s Rules Respecting Track Safety.

Recorded information

The data from the locomotive event recorder (LER) determined the following:

- The train approached the crossing at a speed of 37 mph.

- The locomotive horn was sounded 4 times, beginning at Mile 34.040 (approximately 1780 feet from crossing) and ending at Mile 33.866 (i.e., over approximately 918 feet). The engine bell was also in operation.

- At 0856:12 (Mile 33.846), the throttle was moved to idle and, a second later, an emergency brake application was initiated (Mile 33.836).

- The locomotive traveled another 369 feet prior to the collision which occurred at 0856:17 (Mile 33.70).

- At the time of collision, the train was travelling at 34.9 mph.

- The horn was sounded at the time of impact.

Although not recorded on the LER, post-accident observations determined that the headlight was on full power and the ditch lights were on, in compliance with CROR.Footnote 3

Road grader information

The road grader was a 2009 Volvo Model G970. It was owned by the Rural Municipality (RM) of Paynton. Following the accident, four electronic components were recovered from the heavily damaged road grader. These components were sent to TSB’s Engineering Laboratory for examination.

The following was determined:

- The electronic components did not contain any vehicle performance recording devices with non-volatile memory.Footnote 4

- A diagnostic fault monitoring system (i.e., “CareTrack”) had been installed on the occurrence road grader. Although this system does not record vehicle performance data, it captures diagnostic fault codes and transmits them back to a main base station.

- At the time of the collision, fault codes were sent to the main base station. These fault codes were transmitted as a result of the impact and damage being sustained during the collision with the train.

- A post-accident inspection of the grader determined that the heater was on and the gear shift was in reverse. Due to the damage caused by impact, it could not be determined whether the windows had been open or closed at the time of the collision.

- A driver’s view of an approaching train (to the west) from within the cab of a grader of the same make and model was evaluated. There were no visual impediments attributable to the design of the grader that would have obstructed the view of the approaching train.

Starting with the 2014 models, the road grader manufacturer will install electronic control units (ECU) with non-volatile memory to capture vehicle performance information.

Grader operator information

The grader operator was an experienced heavy equipment operator who had been working for the RM of Paynton since July 2012. Prior to this time, the grader operator had worked as a foreman and an assistant foreman for several other municipalities.

The occurrence crossing is located less than 1.5 km from the municipal facility where road graders are kept. Snow clearing was a part of the operator’s regular duties, and the grader operator was familiar with the crossing. The grader operator had not been involved in any previous crossing accidents. At the time of the occurrence, the grader operator was not wearing any hearing protection and was not using any personal electronic devices. In addition, there is no indication that the grader operator’s ability to operate the road grader had been compromised by any physiological conditions.

Some grader operators in the RM of Paynton partially opened a window on the grader while working around crossings. This was not a mandated safety requirement, but would allow the grader operator to better hear approaching trains. It could not be determined whether the occurrence operator routinely did this.

The task of clearing snow from the roadway in and around crossings involves the following:

- Grader operators must proceed slowly over crossings and occasionally stop on the crossing for a short period of time to position the blades.

- Care must be taken to avoid the grader blades contacting or damaging the running surface of the rails.

- The grader operator must be aware of the proximity of his wing blade to permanent structures beside the track (e.g., sign posts, gate masts).

- Grader operators must remain cognizant of approaching trains and opposing vehicles on the roadway.

At the time of the accident, there was no pre-established requirement for interaction between the railway and the municipality prior to snow clearing operations in the vicinity of crossings. Although discussions about working safely around crossings had taken place, including at a 2003 risk management seminar offered by the Saskatchewan Association of Rural Municipalities (SARM), there was no more recent training provided by the municipality to specifically highlight safe working practices when conducting maintenance activities such as snow removal in close proximity to active railway tracks.

TSB Rail Safety Information Letter concerning municipal snow removal at railway crossings

On 23 December 2013, at 0328, Canadian Pacific (CP) freight train 132-22 (the train) was proceeding eastward at 50 mph through Perth, Ontario, when it struck a dump truck that was occupying the Wilson Street public crossing at Mile 12.44 of the Belleville Subdivision. The public crossing was equipped with an automated warning system (AWS), including flashing light signals, bell and gates. Following the collision, the truck was dragged about 2300 feet before it came to rest at approximately Mile 12.0. The truck was destroyed and the locomotive was damaged. The crossing protection systems at Wilson Street and Drummond Street (Mile 12.20) were also damaged. The vehicle operator sustained serious but non-life threatening injuries (TSB Occurrence R13T0287).

On 06 February 2013, TSB Rail Safety Information Letter 624-01/14 was issued to the relevant municipal authority highlighting the following safety issue:

In many industries, it is common practice to conduct a Safety Briefing prior to commencing work activities. The briefing generally includes a description of the work objectives, the identification of potential risks in the vicinity of the work, and the identification of strategies for mitigating the risks. Safety Briefings are especially important when working with or operating heavy equipment where ambient noise can mask audible warnings, such as crossing bells and the locomotive horn.

In this occurrence, the truck driver was not specifically aware of the risks posed while working near railway infrastructure. Had a Safety Briefing been held and risk mitigation strategies been discussed, an alternative work plan in the vicinity of the crossing would likely have been considered.

Technical standards for railway grade crossings

Transport Canada’s (TC) draft technical standards, entitled Road/Railway Grade Crossings: Technical Standards and Inspection, Testing and Maintenance Requirements (RTD 10), were issued in 2002. These technical standards set out the minimum safety criteria for the construction, alteration, and/or maintenance (including inspection and testing) of grade crossings and their road approaches. RTD 10 standards are not enforceable, but they are used as guidelines by TC, the rail industry, and road authorities when reviewing safety at grade crossings.

RTD 10 contains these indications:

- The required sightline distance at crossings is a function of the type of vehicle for which the crossing is designed, the time it takes the design vehicle to pass completely over the crossing from a stop (departure time), and the maximum train speed.

- Installation of automatic warning systems at crossings is warranted when the forecast cross-productFootnote 5 is 1000 or greater.

- Crossing gates are warranted when the maximum train speed is greater than 50 mph or when there are two or more tracks where trains pass.

TC’s proposed Grade Crossing Standards (2014 February) now specify that a cross-product of 2000 warrants the installation of an automatic warning system.

Crossing information

The occurrence crossing (Mile 33.70 of CN’s Blackfoot Subdivision) is a public passive grade crossing on Highway 674. The passive warning system consists of reflectorized standard railway crossing signs, commonly called crossbucks, positioned at both road approaches (i.e., south and north) and a stop sign on the south side of the crossing. Vehicles using the crossing are primarily automobiles and light trucks. The posted road speed is 50 km/h.

The most recent Transport Canada crossing inspection, as recorded in the Integrated Rail Inventory System for this location, was on 01 May 2002. At that time, the daily traffic count for the crossing was 250 cars and 3 trains, resulting in a cross product of 750. A 2009 traffic count by the Saskatchewan Ministry of Highways and Infrastructure indicated that the average daily traffic count at the crossing was 380 cars and 4 trains, resulting in a cross product of 1520. The next traffic count to be conducted by provincial authorities was scheduled for 2014.

For vehicle traffic traveling south, the sightlines at the crossing in both directions were clear (i.e., RTD 10 clear-sight guidelines were achieved). However, for vehicle traffic traveling north, the sightline to the east was partially obstructed by trees and buildings, necessitating the installation of the Stop sign (Photo 1).

Regulatory safety assessments of crossings

Transport Canada indicates that it is the responsibility of the railway company and the road authority to conduct safety assessments at their grade crossings. Proposed grade crossing regulations (GCR) released in the Canada Gazette Part I on 08 February 2014 would require the railways and road authorities to share detailed information in writing on every crossing within five years of the regulations coming into force. The GCR would not require safety assessments of grade crossings, but Transport Canada expects that sharing this detailed information would make it easier for the railways and road authorities to conduct grade crossing safety assessments voluntarily.

Transport Canada published The Canadian Road/Railway Grade Crossing Detailed Safety Assessment Field Guide in April 2005Footnote 6 to help railway companies and road authorities with safety assessments; it contains these instructions:

- RTD 10 design standards should be referenced during the safety inspection to determine if the conditions warrant upgrading the crossing protection system to automatic warning systems.

- Data such as the daily train volume, average daily traffic count, and maximum operating speed for trains are essential to the crossing assessment.

- “Crossings can be prioritized on the basis of safety performance and any known problems such as vehicles entering the grade crossing when the warning lights are activated or vehicles recurrently blocking the crossing.”

Under the proposed regulations, the information to be shared includes the average daily traffic count, the average annual daily railway movements, and interconnection between traffic signals and warning systems.

Railway companies and road authorities would also be required to share crossing information when a new grade crossing is constructed or when there is an alteration or operational change at an existing crossing. Railway companies would be required to retain the most recent information shared.

Cognitive workload of grader operator

At the time of the occurrence, the road grader was being used to clear snow from Highway 674 after a snowfall the previous night. The operator had cleared part of the roadway south of the crossing and then made a reverse movement back to the crossing in order to clear the rest of the roadway. The collision occurred as the operator was positioning the road grader and was likely to have been adjusting the blade before proceeding south to make another pass.

The cognitive workload of a grader operator is similar to that of a vehicle operator. Both types of operators need to be aware of any vehicles travelling in the vicinity and the position of those vehicles relative to their own. However, operating a road grader imposes additional tasks during certain activities (e.g., setting the grader’s blade, which involves operating several handles controlling the blade’s vertical and horizontal movements).

Driver behaviour at crossings

When stop signs are installed at railway crossings, road vehicles must come to a complete stop ahead of the tracks. From a stopped position, drivers are expected to look in both directions to ensure that the way is clear (i.e., there are no approaching trains) before proceeding. A number of driver behavior studies have established that there are varying degrees of driver compliance with stop signs.Footnote 7,Footnote 8,Footnote 9 While most drivers come to a complete stop and look in both directions (i.e., a high degree of compliance), some drivers do not reduce their speed and may neglect to look for approaching trains (i.e., a low degree of compliance).

TC reportFootnote 10 and a related studyFootnote 11 into railway crossing accidents indicate that

- familiarity with a crossing may encourage drivers to take greater risks, especially when they do not experience any adverse consequences; and that

- although collisions can occur at crossings with any type of crossing protection system, the conversion from passive crossing protection to active crossing protection can result in a substantial reduction in accidents.

Based on dataFootnote 12 for the 10-year period 2001 to 2010, the frequency of train–vehicle collisions was determined to be six times greater at railway crossings equipped only with passive warning systems (e.g., reflectorized standard railway crossing signs and/or stop signs), compared with crossings equipped with automated warning systems (e.g., flashing lights and a bell, with or without gates).

Operation Lifesaver’s “Tips for Snow Plow Operators”Footnote 13 cautions operators to be especially careful at crossings without gates, flashing lights or a bell. The RM of Paynton had not been provided a copy of this training material.

Locomotive horns

Locomotive horns are designed to warn vehicle drivers and pedestrians of an approaching train at railway grade crossings. At crossings without an active warning system, the visual presence of the train, its horn or bell, and its lights may be the only warnings available to a vehicle operator.

Paragraph 14(l)(i) of the Canadian Rail Operating Rules (CROR) states:

At public crossings at grade:

- Trains exceeding 44 MPH must sound whistle signal ¼ mile before the crossing, to be prolonged or repeated, until the crossing is fully occupied.

- Note: A whistle post will be located ¼ mile before each public crossing where required.

- Movements operating at 44 MPH or less must sound whistle signal to provide 20 seconds warning before entering the crossing and continuing to sound whistle signal until crossing is fully occupied.

Despite the CROR requirement to sound the locomotive horn, the effectiveness of the horn as a warning device can be diminished by the attenuation of the sound pressure levels. Forward-propagating sound pressure levels are reduced with

- increased distance travelled by the sound waves;

- increased operating speeds of the locomotive;

- reduced proximity of the horn to the front of the locomotive; and

- increased proximity to any obstructions in front of its flutes such as exhaust vents on the locomotive or nearby buildings and vegetation.

In addition, the effectiveness of the locomotive horn can be affected by certain conditions inside the motor vehicle (e.g., closed windows, engine noise, road noise, radio noise, and fan noise). Nevertheless, some frequencies of the horn sound can still be perceived by the human ear inside a vehicle if these are not masked by other sounds with the same frequencies and higher sound pressure levels. The human ear can detect a signal in the 2.5 to 3 kHz range with a signal to noise ratio of 6.5 dB. This means that the minimum detection threshold is 6.5 dB higher than the background noise at that frequency.Footnote 14 Full alerting to a signal requires a SNR of 9 to 10 dB above the detection threshold.

In February 2010, TC issued the modified Railway Locomotive Inspection and Safety Rules that required the installation of another horn by 01 January 2012 on locomotives operating in the lead position in passenger service and travelling in excess of 65 mph. Design characteristics of this new (i.e., second) horn include:

- The horn must be capable of generating two sound levels: a high-level mode used for emergencies and a lower-level mode used in normal train operations.

- The horn must be placed near the front of the roof, no more than 5 feet behind the rear of the cab, with no obstructions or exhaust outlets ahead of or beside it.

The requirement for this new horn does not apply to locomotives on freight trains.

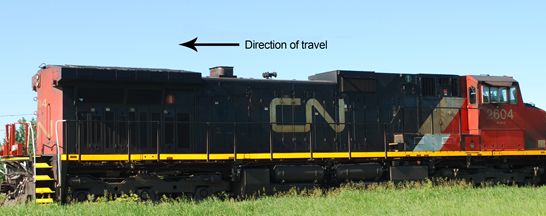

The occurrence locomotive had the horn positioned in the middle of the locomotive in an area on the roof which is recessed. At this location, the horn is below the bulkhead of the locomotive cab. When operating the locomotive in long hood leading orientation, the flutes of the locomotive face opposite the direction of travel (Photo 2).

According to section 11.2 of TC’s Locomotive Inspection and Safety Rules, locomotives must be equipped with a horn that is “capable of producing a minimum sound level of 96 dB(A) at any location on an arc of 30 meters (100 feet) radius subtended forward of the locomotive by angles 45 degrees to the left and to the right of the centerline of the track in the direction of travel.”

The TSB Engineering Laboratory performed train horn audibility testing using the occurrence locomotive (CN 2604) and a road grader of the same make and model as the one in the occurrence.Footnote 15 The tests and test results included the following:

- With the locomotive stationary, initial sound level measurements were taken at a distance of 30 meters directly in front of the locomotive to check the baseline sound levels of the train horn.

- The sound level produced by the locomotive horn when oriented with the short hood leading was 104 dB(A).

- When oriented with the long hood leading, the sound level was measured to be 95 dB(A).

- With the locomotive operating in reverse (i.e., long hood leading) and travelling at the occurrence speed (37 mph) and with the road grader positioned as close as safely possible to the crossing, the locomotive horn was operated continuously up to and through the crossing. Sound measurements were taken from inside the road grader’s cab with the engine running and the heater fan on.

- The main peak sound levels generated by the locomotive horn as the locomotive entered the crossing were 10 to 22 dB(A) above the ambient (i.e., background) noise level.

- One second prior to the locomotive entering the crossing the main peak levels were 10 to 18 dB(A) above the background noise level.

- About 2 seconds prior to the locomotive entering the crossing, the main peak sound levels were no longer above the ambient noise.

- With the locomotive operating in its normal orientation (i.e., cab forward) and travelling at the occurrence speed (37 mph) and with the road grader positioned near the crossing, the locomotive horn was operated continuously up to and through the crossing. Sound measurements were taken from inside of the road grader’s cab with the engine running and heater fan on.

- The main peak sound levels generated by the locomotive horn as the locomotive entered the crossing were each at least 30 dB(A) above the ambient (i.e., background) noise level.

- 1 second prior to the locomotive entering the crossing, the peak levels were between 22 and 30 dB(A) higher than the ambient noise.

- 3 seconds prior to the locomotive entering the crossing, the peak levels were about 15 to 18 dB(A) above the ambient noise.

- 5 seconds prior to the locomotive entering the crossing, 2 of the main peak levels were no longer above the ambient noise level.

Vehicle driver reaction time needs to be factored in once the audio levels are known. The average time needed for the train horn to sound, be recognized by the vehicle driver, and then acted upon is based on commonly used highway design standards referenced in the locomotive horn evaluation study (TP14103E); it includes a brake reaction and visual confirmation time combined with the alerting time and the sound delay due to the distance and speed of sound, and is calculated to be about 4 seconds. Therefore, the train horn should be at an alerting level at least 4 seconds prior to the locomotive entering the crossing. The measurements were taken while the locomotive was stationary. In practice, when the grader is moving, there would be an increased ambient noise inside the cab.

Other related occurrences

Since 2002, the TSB has investigated a number of other crossing accidents where locomotive horn audibility was considered:

- R11T0175 — On 29 July 2011 at about 1040 Eastern Daylight Time, VIA Rail Canada Inc. passenger train 71, travelling westward at 78 mph on the south main track of Canadian National Railway Company’s Chatham Subdivision, struck a pick-up truck on the Pratt Siding Road crossing located at Mile 30.62 near the town of Glencoe, Ontario. The locomotive and all 4 coaches derailed. The vehicle was destroyed and the lone occupant was airlifted to hospital where he later succumbed to his injuries.

- R10W0123 — On 14 June 2010 at about 0700 Central Daylight Time, , Canadian Pacific Railway freight train 290-14 was proceeding southward at 25 mph on the Emerson Subdivision when it was struck by an eastbound garbage truck at the passive crossing at Mile 13.85, near Grande Pointe, Manitoba. As a result of the collision, 22 car bodies derailed. The driver was seriously injured.

- R09V0219 — On 14 October 2009 at 1514 Pacific Daylight Time, southbound VIA Rail Canada Inc. passenger train 198 struck a vehicle on the Dorman Road level crossing at Mile 75.68 of the Victoria Subdivision. As a result of the collision, two occupants of the vehicle sustained fatal injuries and a third was taken to hospital in serious condition.

- R08M0002 — On 19 January 2008 at approximately 1105 Eastern Standard Time, Chemin de fer de la Matapédia et du Golfe inc. freight train 403, travelling westward on the Mont-Joli Subdivision, struck a northbound minivan at the Highway 291 level crossing in the town of Saint-Arsène, Quebec. Two of the five occupants were fatally injured and a third was critically injured.

- R04H0014 — On 06 October 2004, at 1728 Eastern Daylight Time, Canadian Pacific Railway freight train 120-03, proceeding eastward at 28 mph on the Ottawa Valley Railway, struck a northbound vehicle at the River Road public crossing, near Castleford, Ontario. The occupant of the vehicle was fatally injured.

- R04H0009 — On 28 June 2004 at 1836 Eastern Daylight Time, VIA Rail Canada Inc. passenger train No. 49, travelling westward at 93 mph, struck a dump truck at the public crossing at Mile 17.88 of the Smiths Falls Subdivision, near Munster, Ontario. The truck was destroyed, and the occupant was fatally injured.

- R02W0063 — On 02 May 2002 at 1612 Central Daylight Time, eastward Canadian National (CN) train E20251–30 derailed 2 locomotives and 21 freight cars after colliding with a loaded southbound tractor-trailer. The collision occurred at a public crossing near Firdale, Manitoba. Four tank cars carrying dangerous goods sustained multiple punctures and released their products. The products ignited, resulting in a large fire that burned for several days.

Site clean-up

In this occurrence, 16 tank cars containing crude oil (UN 1993) derailed. Of the 16 tank cars involved, 9 were DOT 111, 6 were AAR 211 and 1 was a DOT 111 S (head shield). All of the derailed tank cars sustained damage to the extent that they were uneconomical to repair. Four cars released product (i.e., three were breached and one was leaking through a damaged bottom outlet valve). The total volume of crude oil being transported by the 16 cars was about 1 338 300 L.

After the accident, about 98% of the crude oil was accounted for as follows:

- Approximately 1 077 000 L of crude oil was sent back to the Lashburn transfer facility for reloading.

- Approximately 48 000 L was sent to Maidstone to be reprocessed for delivery to customer.

- Approximately 76 600 L was sent to Unity for deep well disposal.

- Approximately 106 000 L was picked up by other means and appropriately disposed of at a landfill.

The removal of debris and crude oil from the site was completed by 01 February 2013.

TSB Laboratory reports

The following TSB Laboratory reports were completed, and are available on request:

- LP047/2013 – Locomotive Audio Level Analysis

- LP023/2013 – Download of Vehicle Data Recorder

Analysis

Neither track condition nor train operation was considered causal or contributory to the accident. The analysis will consider driver behaviour, locomotive horn effectiveness, and safety assessments of passive grade crossings.

The accident

The accident occurred when train L51141-23 collided with the stationary road grader that was occupying the public crossing at Mile 33.70 of the Blackfoot Subdivision. The collision propelled the grader approximately 519 feet eastward and resulted in the operator sustaining fatal injuries. The locomotive and 16 tank cars carrying crude oil (UN 1993) derailed.

Cognitive workload

The cognitive workload of a grader operator is similar to that of a vehicle operator. However, for certain activities, grader operators have additional tasks, such as adjusting the grader’s blades. Therefore, with the grader operator’s attention likely focused on resetting the road grader’s blades for the snow clearing in the vicinity of the crossing, the grader operator did not detect the approaching train from the west.

Driver behavior

Advance warning signs, stop signs, and passive warning devices at railway crossings inform vehicle drivers of the presence of a crossing. However, familiarity with a particular railway crossing may encourage drivers to take greater risks, especially when they do not experience any adverse consequences. In this occurrence, the grader operator was familiar with the crossing due to its proximity to the municipal facility for storing road graders and from working around the crossing previously—and had not been involved in any crossing accidents before. If drivers do not experience adverse consequences when exposed to risk, their situational awareness at railway crossings may transition from a state of high alertness to a more relaxed state over time, increasing the risk of crossing accidents.

Performing activities such as snow removal over active railway tracks requires a grader operator’s concentration to be divided among competing tasks. At a time when the grader operator needs to look in both directions for the approach of a train, he or she must also consider blade positioning, side clearance, and opposing road vehicles. The risk is greatest at passively protected crossings. Although some grader operators worked with their windows open (or partially open) around crossings, it was not part of a mandated safety policy. It could not be determined whether this practice was followed by the occurrence operator.

The municipality had not identified the risks or established safe working practices for municipal employees engaged in snow removal (or other maintenance activities) near active railway tracks. The grader operator had not been trained to identify the potential hazards and safeguard himself from danger. There was no briefing process in place to help the grader operator identify and mitigate risks before starting snow removal activities at the crossing. If measures are not taken to fully protect municipal maintenance activities near active railway tracks, there is an increased risk of crossing collisions during these activities.

Locomotive horn auditory levels

Locomotive horns are designed to warn vehicle drivers and pedestrians of an approaching train at railway grade crossings. At crossings without an active warning system, the visual presence of the train, its horn or bell, and its lights may be the only warning available to a vehicle operator. The Canadian Rail Operating Rules require that trains sound the horn to provide 20 seconds of audible warning when traveling less than 44 miles per hour and that the horn continues to be sounded until the crossing is fully occupied.

Several factors, including the speed of the train and the placement and orientation of the horn on the locomotive, can affect the efficacy of the horn. In this occurrence, the locomotive was being operated with the long hood leading (i.e., in reverse orientation) with the flutes of the locomotive horn facing opposite the direction of travel. The locomotive horn was positioned on the roof and in the middle of the locomotive, below the bulkhead of the locomotive cab.

From the stationary measurements, it can be seen that changing the locomotive orientation from short hood leading to long hood leading attenuated the locomotive horn audio levels by about 9 dB. This attenuation increased once the locomotive was in motion. With motion (i.e., 37 mph) included, the horn audio level difference between a short hood leading locomotive and a long hood leading locomotive was 15 to 20 dB.

It was shown that locomotive horn audio levels drop off significantly the further back the train is from the crossing. When a locomotive in a short hood leading configuration entered the crossing the peak horn levels were at least 30 dB above the background noise of an idling grader; at just 5 seconds back, these levels were down to a maximum of 6 dB above the background noise. When a locomotive in a long hood leading configuration entered the crossing, the peak horn levels were 10 to 22 dB above the background noise; at 2 seconds back, these levels were no longer above the background noise.

The human ear can detect a signal in the 2.5 to 3 kHz range with a signal to noise ratio (SNR) of 6.5 dB. This means that the minimum detection threshold is 6.5 dB higher than the background noise at that frequency.Footnote 16 Full alerting to a signal requires a SNR of 9 to 10 dB above the detection threshold.

This means that a train horn may not be recognized until the train is about 3 seconds from the crossing in short hood leading configuration, or 1 second from the crossing in long hood leading configuration—or, at 37 mph, 162 feet and 54 feet from the crossing, respectively. Furthermore, given that the expected reaction time for the grader operator was about 4 seconds, it is likely that the operator would not have been able to get out of the way of the train, regardless of the locomotive’s orientation.

If locomotive horn orientation and placement are not optimized for maximum forward sound pressure propagation, the effectiveness of the horn as an auditory warning will be reduced, increasing the risk of a crossing accident.

Safety assessments of crossings

Both train and vehicle traffic at the occurrence crossing has increased over the years. The risk level of a crossing is determined by a number of factors in addition to train and vehicle traffic, such as the number of tracks, train speed, and the likelihood of a train meet.

Crossings can be prioritized on the basis of safety performance (i.e., accident trend) and other known problems such as vehicles recurrently blocking the crossing. At the occurrence crossing, the average daily traffic count in 2002 was 250, increasing to 380 in 2009. The total number of trains was 3 per day in 2002, increasing to 4 per day by 2009. The cross-product was 750 in 2002, increasing to 1520 in 2009, with the next update due in 2014. A cross product of 2000 along with the criteria above would warrant considering upgraded crossing protection.

Proposed grade crossing regulations would remove the mandatory requirements for safety assessments at crossings, but the new requirement that detailed information be shared between the railways and the road authorities within 5 years of the promulgation of the regulations may lead to voluntary safety assessments. If detailed crossing assessments are not conducted regularly, however, changes in operational conditions at the crossing (e.g., increases in traffic volume) that may warrant upgraded crossing protection will not be identified, increasing the risk of a crossing accident.

Vehicle performance recording devices on graders

The road grader did not have any vehicle performance recording devices with non-volatile memory. Vehicle performance information can assist in accident investigations.

Findings

Findings as to causes and contributing factors

- The accident occurred when train L51141-23 collided with the stationary road grader that was occupying the public crossing at Mile 33.70 of the Blackfoot Subdivision.

- With the grader operator’s attention likely focused on resetting the road grader’s blades for snow clearing in the vicinity of the crossing, the operator did not detect the approaching train from the west.

- With the locomotive being operated in the long hood leading orientation and with the horn placed in the middle of the locomotive in a recessed location, the forward sound pressure propagation was reduced.

- The sound level inside the closed cab of the road grader (i.e., from the engine and the fan) further reduced the effectiveness of the locomotive horn, resulting in an audible warning of less than 2 seconds.

Findings as to risk

- If drivers do not experience adverse consequences when exposed to risk, their situational awareness at railway crossings may transition from a state of high alertness to a more relaxed state over time, increasing the risk of crossing accidents.

- If locomotive horn orientation and placement are not optimized for maximum forward sound pressure propagation, the effectiveness of the horn as an auditory warning will be reduced, increasing the risk of a crossing accident.

- If detailed crossing assessments are not conducted on a regular basis, changes in operational conditions at the crossing (e.g., increases in traffic volume) that may warrant upgraded crossing protection will not be identified, increasing the risk of a crossing accident.

- If measures are not taken to fully protect municipal maintenance activities near active railway tracks, there is an increased risk of crossing collisions during these activities.

Other findings

- The road grader did not have any vehicle performance recording devices with non volatile memory.

Safety action

Safety action taken

On 21 November 2013, TSB issued Rail Safety Advisory RSA 14/13 related to the reduced effectiveness of the locomotive horn when the locomotive is operated with the long hood leading (i.e., in reverse orientation).

In reply to RSA 14/13, Transport Canada indicated that it had asked the Transportation Development Centre to undertake a research project on the audibility of horns to analyze a horn’s effectiveness when long hood leading. TC acknowledged the importance of this to railway safety in Canada, and indicated that the research project would be assigned high priority in the next fiscal year.

This report concludes the Transportation Safety Board’s investigation into this occurrence. the Board authorized the release of this report on . It was officially released on 12 August 2014.