Crossing collision and derailment

VIA Rail Canada Inc.

Train number 60

Mile 138.21, Kingston Subdivision

Mallorytown, Ontario

The Transportation Safety Board of Canada (TSB) investigated this occurrence for the purpose of advancing transportation safety. It is not the function of the Board to assign fault or determine civil or criminal liability. This report is not created for use in the context of legal, disciplinary or other proceedings. See Ownership and use of content. Masculine pronouns and position titles may be used to signify all genders to comply with the Canadian Transportation Accident Investigation and Safety Board Act (S.C. 1989, c. 3).

Summary

On 15 July 2008, at approximately 1525 eastern daylight time, VIA Rail Canada Inc. passenger train No. 60, travelling eastward on the north main track of the Canadian National Kingston Subdivision, struck a loaded tractor-trailer immobilized at the public crossing at Quabbin Road, Mallorytown, Ontario, and derailed. The locomotive engineer had applied the brakes, but the train was unable to stop before colliding with the tractor-trailer. The trailer and equipment it was carrying was destroyed. The truck driver had exited the tractor before impact and escaped unharmed. The operating locomotive engineer and four train passengers received minor injuries.

Ce rapport est également disponible en français.

1.0 Factual information

1.1 The accident

On 15 July 2008, VIA Rail Canada Inc. (VIA) train No. 60 (the train) was travelling eastward on the north main track at 83 mph. At approximately 1515,Footnote 1 approaching the whistle post, one quarter mile west of Quabbin Road, in Mallorytown, Ontario (see Figure 1), the train crew observed a tractor-trailer carrying heavy equipment stopped on the north main track. The operating locomotive engineer also observed a person standing on the track, between the stopped truck and the approaching locomotive, waving his arms. He immediately applied the brakes and sounded the locomotive horn. The person then ran to the south, away from the track.

Road construction was underway on provincial Highway 2, located south and west of Mallorytown, parallel to the rail line. A cold-planer (see Photo 1) was being used to remove deteriorated roadway asphalt before repaving the road surface. After completing the assigned work, the cold-planer, which weighed approximately 11.5 tons (23 000 pounds), was loaded onto a lowboy tractor-trailer unit to be moved to another location.

The truck operator was unfamiliar with the Quabbin Road crossing. To detour around the recently laid asphalt, the driver was instructed to follow a pilot vehicle driven by a person familiar with the roads in the area. The lowboy truck departed in a three-vehicle convoy, with a dump truck leading and a water tank truck trailing.

The three vehicles proceeded westward, then northward across the railway tracks to Quabbin Road, where they turned right and proceeded eastward. On the approach to the Quabbin Road level crossing (see Photo 2 and Figure 2), the driver reduced speed to negotiate a 90-degree turn in the road approximately 155 feet from the crossing. As the driver entered the crossing, the lowboy trailer became immobilized.

The driver attempted unsuccessfully to reverse. Then, the following 20-ton water truck was moved close to the lowboy truck. A chain was attached and another unsuccessful attempt was made to move the truck. These actions took approximately seven minutes. None of the vehicle drivers had noticed the 1-800 emergency number posted on the signal bungalow (see Photo 3).

Seconds later, the crossing signals activated and the driver of the lowboy truck ran towards the approaching train to warn it to stop. The water truck driver unhooked the chain and backed clear just as the train entered the crossing and struck the lowboy trailer.

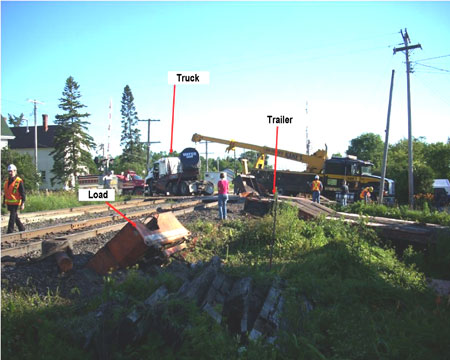

The tractor-trailer was struck by the front of the locomotive between the rear axle and the front portion of the trailer. The tractor separated from the lowboy trailer and remained on the roadway south of the crossing. The trailer was pushed into the roadway embankment beside the north track. The cold-planer slid off the trailer, and came to rest beside it (see Photo 4). The 270 kg connector between the trailer and the tractor was torn off and became lodged under the locomotive, causing it to derail. The connector then began to roll under the train, derailing the baggage car behind the locomotive and slicing open its floor. The train came to a stop approximately 2700 feet (823 m) east of the crossing.

1.2 Weather

At the time of the accident, the weather was partly cloudy, with a visibility of 15 miles (24 km), a temperature of 21°C, and winds at 13.8 mph (22.8 km/h).Footnote 2

1.3 Train information

The train, en route from Toronto, Ontario, to Montréal, Quebec, consisted of one locomotive, a baggage car and six coaches. There were 207 passengers and 7 crew members on board.

1.4 Personnel information

The operating crew of the train consisted of two locomotive engineers who were qualified for their respective positions. They met company and regulatory fitness and rest standards.

1.5 Kingston Subdivision

Train movements on the multiple-track Canadian National (CN) Kingston Subdivision are governed by the Centralized Traffic Control System of the Canadian Rail Operating Rules (CROR) and supervised by a rail traffic controller located in Toronto. The authorized timetable speed at the accident location was 90 mph for this type of passenger train equipment.

1.6 Particulars of the track

In the vicinity of Mile 138.21, the Kingston Subdivision consists of two tracks: the north and south main tracks. The Quabbin Road crossing is located on tangent track. Approximately 30 freight trains and 24 passenger trains operate over the tracks on a daily basis. The Kingston Subdivision is one of the most heavily travelled and highest-speed lines in Canada.

Between Montréal and Toronto, there are approximately 180 public crossings and another 180 private or farm crossings along the Kingston Subdivision. Almost all of the public crossings are equipped with flashing lights, bell and gates; the balance being equipped with crossbucks at the crossings and typically with advance warning signs on the approaches.

1.7 Particulars of the crossing

The Quabbin Road crossing has existed since the construction of the Kingston Subdivision in 1856. The crossing was equipped with flashing lights, a bell and gates. Stop lines were painted on the road surface approximately 24 feet from each side of the crossing. A 1-800 emergency number was posted on the signal bungalow; however, the words "24 Hr. Emergency 1 800 617 6617" on the emergency signage were at least partially obscured by the overhang of the roof.

The crossing angle was approximately 65 degrees. The crossing surface between the most northerly and southerly rails consisted of asphalt and wooden planks and was in good condition. When measured after the accident, the crossing gradients on the southbound and northbound approaches were 7.0 per cent and 7.4 per cent respectively (see Figure 3).

In 1966, the Engineering Branch of the Board of Transport Commissioners for Canada (BTC) documented the average approaching grades as 8.0 per cent ascending from the north, and 7.5 per cent from the south. On 16 January 1967, the BTC forwarded to the United Counties of Leeds and Grenville and to CN an Engineering Branch recommendation to improve the approach grades to 5 per cent. CN track maintenance records indicate that the crossing had been surfaced several times between 2002 and 2008, but there is no indication that this work significantly changed the profile of the crossing. Transport Canada (TC) records the approaching grades for this crossing as 5 per cent.

1.8 Crossing warning system

Post-occurrence testing determined that the crossing warning system was operating as designed and in accordance with TC's General Order E-6 regulations. A review of railway inspection and maintenance records for this crossing revealed no deviation from the regulatory requirements.

1.9 Particulars of the roadway

Quabbin Road is a two-lane, undivided arterial roadway with a posted speed limit of 50 km/h in the vicinity of the crossing. The maximum gradient of the roadway on the southbound approach to the crossing was 8.6 per cent ascending.

Roadway signage on both the north and south approaches consisted of a railway crossing advance warning sign, depicting a single railway track. There was no signage restricting truck traffic or advising drivers of the hazards the crossing might pose to low ground clearance vehicles.

According to the TC Integrated Rail Information System (IRIS) crossing database, the Quabbin Road crossing was last inspected by a TC railway safety inspector in September 2002. At that time, the estimated traffic volume at the crossing was 300 vehicles per day. The proportion of heavy vehicles was not recorded.

1.10 Recorded information

Data extracted from the locomotive event recorder indicated that the train was travelling at 83 mph approaching the accident site, in throttle position No. 8 (maximum). The ditch lights were on, and the headlights were on bright as required by regulation. The locomotive horn was sounded at the same time as a full service brake application was made. The train stopped 36 seconds after the brake application. The train travelled 2409 feet from the time when the brakes were applied to the point where it struck the truck. It continued another 2700 feet before coming to a stop.

1.11 Tractor-Trailer information

1.11.1 Tractor information

The truck (tractor) was a 1997 Mack, model CH613, owned by Rotomill Services Ltd. The tractor was licensed by the Province of Ontario and had passed its last annual safety inspection. It was not equipped with an electronic data recorder; therefore, it was not possible to determine exactly how long the truck was immobilized on the crossing before it was struck. However, information collected during the investigation indicated that it was on the crossing for about seven minutes.

1.11.2 Trailer information

The lowboy trailer (see Photo 5) was a 1976, 48-foot, model TC3, manufactured by Rogers Bros. Corp., and licensed by the Province of Ontario. The overall length of the tractor/trailer combination was approximately 60 feet (18.28 m). A full mechanical inspection had been performed 12 months before the accident, and a post-accident examination was conducted on site. In addition, the required pre-trip inspection had been conducted. No deficiencies were noted.

The trailer was designed to be lowered and raised for the purposes of loading and unloading equipment while disengaged from the tractor. A small engine mounted on the trailer produced the power necessary to operate its hydraulic lifting mechanism. The design vertical ground clearance for the underside of the unloaded trailer involved in the accident was 7 inches (17.8 cm) minimum.

Some newer model trailers do not have to be disengaged from the tractor and are designed so that the trailer height can be easily adjusted before encountering a clearance obstacle. However, the adjustment has to be made when the truck is stationary. The adjustment system is powered by the tractor's air supply system.

There are more than 10 000 gooseneck or other types of low-clearance trailers registered in Canada.Footnote 3 Although the minimum vertical ground clearance varies by trailer design, all are by nature low, as their purpose is to maximize vertical distance between the trailer floor and any potential overhead obstruction, such as a bridge or wires, and to facilitate loading of equipment without the need for ramps and/or blocking of the trailer.

1.11.3 Truck operator information

The truck driver had a valid class "A" licence. In the Province of Ontario, possession of an "A" licence permits a person to drive any tractor-trailer combination. The driver had been operating heavy trucks, including tractor-trailers, for approximately eight years and was familiar with the operation of lowboy trailers. In Ontario, truck drivers are not required to receive training in what to do when their equipment becomes immobilized on a railway right-of-way. The driver in this occurrence had not received any training of this nature.

1.11.4 Sources of information for drivers of lowboy trucks

CN has information intended for the use of operators of lowboy equipment on its website. This information (currently found at http://www.cn.ca/en/corporate-citizenship-public-issues-safety-precautions.htm) was added as a result of a National Transportation Safety Board (NTSB) recommendation following a similar November 2000 collision in the United States.Footnote 4 In its final report, the NTSB recommended that Section 11-703 of the Uniform Vehicle Code and Section 383.51 of the Code of Federal Regulations be revised to encompass low ground clearance vehicles and slow-moving vehicles. The NTSB also recommended that individual states adopt processes that would require the operators of such equipment to contact the railway.

Operation Lifesaver, a public awareness and education program funded by the railways and TC, has information for drivers of heavy and/or lowboy equipment in its professional drivers presentations and educational material. This includes specific reference to the hazards associated with humped crossings and the need to pre-plan and find alternative routes. The information also advises drivers where to find the 1-800 emergency number located at all level crossings.

1.12 Damage to tTrack and equipment

Approximately 2500 feet of the north main track was damaged, resulting in the replacement of around 600 ties. The locomotive sustained severe damage to its front end, and its running gear (see Photo 6a). The baggage car sustained damage to its lead truck (see Photo 6b) and to its interior flooring.

1.13 Regulatory requirements

TC's Railway Safety Directorate regulates railway safety in accordance with the Railway Safety Act (RSA) of 1989.

1.13.1 Railway-highway rrossing at grade regulations

Regulations respecting the construction of a crossing of a railway and a highway at grade can be found in the Railway-Highway Crossing at Grade Regulations (SOR/80-748). These regulations contain requirements for the design and construction of crossings, including the gradient of the approaches of a highway. The maximum gradient of 5 per centFootnote 5 is based on the ability of highway vehicles to easily and quickly clear the crossing after having stopped at the crossing.

The regulations make no reference to signage requirements apart from signboards at public crossings. The Quabbin Road crossing did not meet the gradient requirements of the 1980 regulations, which apply to crossings constructed or reconstructed after those regulations came into force. The majority of railway crossings in Canada were constructed before 1980.

1.13.2 Engineering Work Related to Railway Works

TC has published a guidelineFootnote 6 to assist responsible parties when conducting engineering work that affects railway operations. In Section 1.3.1, the roles and responsibilities of railway companies and road authorities are defined:

1.3.1 Railway Companies, Utility Companies and Road Authorities

These parties may own, manage, maintain, construct, or alter railway works or other non-railway works that may affect railway safety.

They take overall responsibility for ensuring their works comply with Section 11 of the RSA, and have a duty to retain professional engineers to comply with its provisions.

They must ensure that resources are made available for the prudent implementation of engineering work related to railway works in accordance with sound engineering principles, safety, and environmental principles. The engineering work must be carried out in accordance with applicable legislation and regulations.

These parties must be prepared to provide to Transport Canada, upon request, verification that professional engineers have taken responsibility for any part of the engineering work.

In section 1.3.4, the regulator's responsibilities are defined:

1.3.4 Rail Safety Regulators

These parties are responsible for regulating and enforcing the RSA and other related legislation and guidelines related to rail safety. Transport Canada is the rail safety regulator for the RSA.

The responsibilities of the rail safety regulators include:

- ensuring compliance with Section 11 of the RSA;

- conducting audits to assess compliance;

- provide counselling with respect to the requirements and the potential consequences of non-compliance; and

- taking enforcement action under the RSA as required.

A railway or a road authority that contemplates new signal or crossing works, altering existing works or foresees changes in road or rail operations should communicate with the other party and ensure that appropriate engineering work is carried out.

1.13.3 RTD 10 – Road/railway grade crossings: Technical standards and inspection, testing and maintenance requirements

TC has been developing new level crossing regulations for over 20 years.Footnote 7 This draft and its related technical manual present far more detail on crossing design than existing requirements.

TC's draft technical standards entitled Road/Railway Grade Crossings: Technical Standards and Inspection, Testing and Maintenance Requirements (RTD 10), issued in 2002, was to be incorporated by reference into the new level crossing regulations. In the interim, it has been used as a de facto standard by TC and industry/road authorities when reviewing safety at level crossings. For RTD 10, several types of vehicle design were used to establish the geometric requirements at crossings. However, lowboy truck design was not considered and RTD 10 provides no guidance on vertical alignment design of crossing approaches.

1.13.4 Ontario Ministry of Transportation requirements

The Ontario Ministry of Transportation (MTO) requires special permits for the transportation of heavy equipment. A permit specifies timing and routes, and whatever special arrangements are made to accommodate an oversized load's passage. Railways will arrange for crossing occupancy protection. Unless lowboy equipment is carrying an oversized load, it does not require a special ministry permit. The load involved in this occurrence was not oversized.

Section E 12.2, Vertical Alignment, of MTO's design standards for railway crossings notes the following:

The grade of a road approaching a railway crossing should be flat to permit vehicles to stop safely when necessary and to proceed across without difficulty. The vertical alignment should produce acceptable geometries necessary to prevent low-clearance vehicles from becoming caught on the tracks, therefore, providing the crossing surface at the same plane as the top of the rails for a distance of one metre outside of the rails. The approach grade of the highway should also not be more than +1%, nor less than - 2% from the top of the nearest rail at a point 10 m from the rail unless track superelevation dictates otherwise. Section 10 of the RSA should be consulted for specific controls of the road approach gradients. The grade of the approach of any grade crossing must be in accordance with Part (2) of Section 10 of the RSA.

The MTO plans to bring its Geometric Design Standards for Ontario Highways in line with TC's document RTD 10 once RTD 10 is incorporated into TC regulations.

1.13.5 Transport Canada crossing inspection programs and procedures

Inspection programs are developed and implemented using risk management principles. Programs provide an understanding of the current state of the safety of grade crossings, safety trends, and compliance with regulations, standards and rules, with emphasis on areas of higher risk. Activities for monitoring compliance and safety at grade crossings involve audits, inspections, accident follow-up and the review of complaints. Inspectors are also required to enforce legal obligations, which can result in the issuance of Notices and Notices and Orders under Section 31 of the RSA, and prosecution of corporations and individuals.

In any given year, each region will conduct a number of proactive programs, such as:

- a grade crossing general condition program;

- a crossing warning system general condition program;

- a cursory crossing program—tied to the track monitoring program; and

- targeted programs to assess areas of particular concern.

A typical grade crossing safety inspection assesses the physical characteristics of the crossing, its environment, the interaction between road and rail operations, and accident history. For each type of inspection at a grade crossing, a railway safety inspector will examine basic elements including: general condition of sight-lines, crossing surface condition, presence and adequacy of crossing signs, and general condition of automated warning devices, if installed.

When TC inspects crossings, the approach grades are measured as part of that process. Measurements are taken at a number of points on the approach slope to determine the average grade. It is this average grade, not the maximum grade, that is recorded. This methodology is not designed to assess the crossing suitability for lowboy vehicles or trailers. These vehicles have the propensity to hang up, usually at the point where the plane of the approach slope and the plane of the crossing surface intersect.

In 2002, TC recorded the approach grades for various crossings along the Kingston Subdivision where they were greater than 5 per cent. The Quabbin Road crossing had grades measured at 5 per cent on both approaches when inspected in September 2002.

A post-accident survey by TSB investigators revealed that 4 of 5 crossings examined in the vicinity of Quabbin Road had approach grades greater than or equal to 5 per cent.

1.14 Canadian National track maintenance procedures at crossings

When conducting track maintenance and repairs in the vicinity of crossings (including lifting, lining and undercutting), the elevation of the track may change. In these circumstances, crossing grade and slope may be affected. When work is completed, CN undertakes paving and crossing maintenance activities to restore crossing surface in compliance with relevant Engineering Standard Practice Circulars. The railway does not, however, undertake any actions to address how changes to the track may affect the crossing profile for vehicles, nor does it notify TC of its activities. The only communications are with the local road authority to arrange for the closure of the crossing for the maintenance work.

1.15 Crossing occurrences involving heavy trucks

For the purposes of this report, heavy trucks include tractor-trailer units and tank trucks carrying dangerous goods, such as fuel delivery vehicles. Since 1995, 646 crossing accidents involving heavy trucks were reported to the TSB. In total, 9 accidents involved dangerous goods tank trucks, 222 accidents involved large trucks, and 415 accidents involved tractor-trailers. Several of these accidents involved trucks that were either immobilized or moving very slowly over the crossing.

Regarding the main tracks of the Kingston Subdivision, TSB records indicate that, since 1995, there have been 11 accidents involving heavy trucks, including 4 accidents where the trucks were immobilized on the crossing. Three of these occurrences resulted in derailments.

1.15.1 Occurrences involving lowboy trucks

There has been one other recent crossing collision and derailment accident on the Kingston Subdivision involving a lowboy trailer:

On 13 May 2002, at approximately 0915 eastern daylight time, VIA Rail Canada passenger train No. 52, travelling eastward on the south main track of the Canadian National Kingston Subdivision, struck a loaded tractor-trailer at the public crossing at Mile 181.71, Kingston, Ontario. The locomotive engineer had applied the brakes in emergency, but the train was unable to stop before colliding with the tractor-trailer. The two truck occupants exited the tractor before impact and escaped unharmed. The operating locomotive engineer suffered minor injuries (TSB report R02T0149).

In relation to occurrence R02T0149, the TSB issued Rail Safety Advisory 03/02, Crossing Issues Related to "Low Boy" (Gooseneck) Trailers. In response, TC acknowledged the risk presented by low-clearance vehicles. TC committed to working with road and railway authorities to identify crossing locations suitable for use by heavy/large vehicles, and towards the adoption of a standardized low ground clearance warning sign. In 2004, research into lowboy trailer clearances determined that some designs of low-clearance trailers cannot negotiate crossing approaches with a gradient at or near the 5 per cent approach limits set out in current regulations.Footnote 8

Although low-clearance crossing signs have been installed at some locations, there is still no standardized warning sign in Canada.

Low ground clearance highway-railway warning signage is standardized in the United States through the Department of Transportation Manual of Uniform Traffic Control Devices (MUTCD). Chapter 8, Section 8B.17, sets forth guidance for the posting of such signs. It states, in part, "if the highway profile conditions are sufficiently abrupt to create hang-up situation for long wheelbase vehicles or for trailers with low ground clearance, the Low Ground Clearance Highway-Rail Grade Crossing (W10-5) sign [see Figure 4] should be installed in advance of the highway-rail grade crossing."

1.16 Hazard detection and warning systems

1.16.1 Detection of lowboy vehicles

While technology has existed for many years to alert drivers of oversize vehicles of overhead clearance restrictions, there do not appear to be any technologies in common use to alert drivers of lowboy trucks that certain routes are unsuitable for their operation. TC is monitoring a United States research and development project designed to evaluate the reliability of an in-pavement system to detect and warn low-clearance vehicles before their arrival at a crossing.

1.16.2 Detection of obstructed crossings

In the United States, the John A. Volpe Center performed an evaluation of the four-quadrant gate/obstruction detection system along Amtrak's northeast high-speed rail corridor in Groton, Connecticut, United States.Footnote 9 The system detects stationary objects on railway crossings, and indications of the performance of this type of grade crossing safety enhancement system are that it could be a valuable option for high-speed rail corridors where in-cab signalling or an equivalent type of train control system is used.

1.16.3 Detection of Crossings Unsuitable for Low-Clearance Vehicles

Currently, there is no ongoing program to identify crossings that may present a risk to low-clearance vehicles. Recently, industry and government has supported university research into technology designed to enhance the detection of ground hazards that can present a risk to safe railway operations. Some of this technology, such as light detection and ranging (LiDAR) systems, have shown promise in this area, and may also prove a promising tool for the timely identification and prioritizing of grade crossing design and maintenance issues. To date, a conceptual overview of what could be done to assess the details of road geometries at crossings has not been undertaken.

2.0 Analysis

2.1 Introduction

The accident occurred when the lowboy tractor-trailer became immobilized on the crossing and was subsequently struck by a passenger train about seven minutes later. The condition of the track, railway equipment and train handling did not contribute to this accident. The analysis will focus on the factors that caused the tractor-trailer to become immobilized and why the train was not stopped before striking the vehicle.

2.2 The accident

The crossing had last been inspected by TC in 2002 and at that time it was reported to meet post-1980 regulatory requirements of 5 per cent. However, in both 1966 and after this accident, the measured approach grades exceeded 7 per cent, and the maximum grade exceeded 8 per cent. This suggests that the TC value was inaccurate. The collision and derailment occurred when the low-clearance lowboy vehicle became immobilized on a humped crossing with excessively steep approaches, and was struck by an eastbound passenger train.

Although the steep approach grade to the horizontal crossing surface created a profile that could not be cleared by the lowboy truck, there were no highway warning signs to alert drivers to this risk. No other compelling information or technology was available to alert the truck operators to the excessive crossing profile.

When the vehicle became stuck on the crossing, the operators were focused on efforts to free it. They were not trained in procedures to follow when their truck becomes stuck on a railway. The emergency signage was not sufficiently conspicuous or compelling to be noticed by the vehicle operators. No attempt was made to make an emergency call. Although the truck had been on the crossing for about seven minutes, the truck operators did not recognize the urgency of alerting railway authorities, and did not alert railway operations. It was only when the crossing signals activated that they became aware of the risk of collision.

The VIA train was travelling at 83 mph. At this speed, by the time the crew could see the truck on the crossing, there was insufficient time to stop the train. The train crew would have required some form of advanced warning to avoid the accident. In the absence of any technology to automatically alert crews to an object blocking the crossing, the crew was reliant on an emergency radio broadcast from rail traffic control. However, since railway officials had not been advised that the crossing was blocked, no emergency radio broadcast was made.

Every time significant road or track maintenance work is undertaken at a crossing, it has the potential to change the gradient of the road approach. The track was surfaced multiple times at the Quabbin Road crossing since 2002, but there was no railway, road authority or regulatory process to ensure the approach grades to this crossing were inspected before it was reopened. Inspection protocols were insufficient to identify crossings with problem profiles which could not be negotiated by lowboy vehicles.

2.3 Risks associated with low-clearance vehicles

There are thousands of low-clearance vehicles on Canada's highways. In addition to lowboy trailers, there are automobile carriers, long-distance moving tractor-trailers, and special purpose vehicles with substructures mounted between the trailer wheelbase. These vehicles present an ongoing risk at crossings, particularly at non-standard crossings where rapid changes in slope or approach gradient increase the likelihood that a low-clearance vehicle will ground out. Any crossing where tracks are elevated significantly above the general highway grade profile presents a risk of trucks becoming immobilized with the resulting risk of collision and derailment of trains. This risk is especially significant in high-speed rail corridors.

2.4 Approaches to and clearances at railway crossings

Following this accident, the TSB conducted surveys at five crossings. Four of the five crossings exceeded the 5 per cent standard; however, there were no signs to alert or restrict low-clearance vehicle operation over the crossings.

A truck driver approaching a highway/railway crossing with any type of large vehicle understands that the presence of an uneven surface requires that the tracks be crossed at a reduced speed. It is probable that drivers of low-clearance vehicles are aware of the potential for hanging up on crossings with steep gradients. However, it is also probable that drivers cannot assess the exact gradient of upcoming level crossings unless clear information to that effect is available. Neither the gradient nor the risk it presents to a vehicle was identified at this crossing, even though the steep approach grade to the horizontal crossing surface created a profile that could not be cleared by a low-clearance truck.

2.5 Perception and awareness of danger

Because the driver was unfamiliar with the crossing, he was relying on the driver of the lead truck to guide him safely or alert him to any hazards. The primary purpose of the driver of the lead (pilot) vehicle was to guide the other vehicles around the newly laid section of pavement on the nearby highway. However, neither the lead vehicle driver nor the driver of the lowboy vehicle recognized the risks presented by the steep crossing approach. Furthermore, there were no highway signs to alert drivers that a humped crossing was ahead. Once the truck became hung up, no attempt was made to make an emergency call, and there was no recognition of the emergency sign on the signal bungalow. Railway emergency signage was not sufficiently compelling for the driver to alert railway authorities once his truck became immobilized on the crossing. While there are thousands of trucks hauling lowboy trailers in Canada, there is no specific training for their drivers to explain the problems they might experience at railway crossings. Therefore, training of truck drivers is insufficient to ensure drivers recognize the risk presented by non-standard railway crossing profiles.

2.6 Roadway signage requirements

Drivers of large vehicles using highways are presented with a number of warning and advisory signs to assist them in determining a safe course of action. For example, roadways passing below overhead structures have signs advising drivers of minimum clearances. Additionally, oversized loads require special provincial permits, at which time specific routes are mapped out and special arrangements are made to accommodate passage. There was no signage on Quabbin Road to warn that lowboy trailers would encounter clearance problems at the upcoming level crossing, nor were there signs to restrict this type of truck traffic from using this route. The only visual warning on the crossing approach was an advanced railway crossing sign depicting a single set of tracks. Unsigned humped crossings, especially on high-speed rail corridors, present a risk of collision when lowboy vehicles are not warned of the situation ahead, and then become immobilized on the crossing.

2.7 Crossing grade inspection requirements

TC's crossing inspection protocols do not consider the maximum approach grade in the vicinity of crossings. Instead, an average gradient figure is used. Consequently, its inspection protocols can underestimate the impact of maximum approach grades and the risks inherent for low-clearance vehicles using the crossing. Current TC inspection practices are insufficient to identify non-standard crossing profiles to ensure that those using these crossings are alerted to the risks and can take preventive measures.

3.0 Findings

3.1 Findings as to causes and contributing factors

- The collision and derailment occurred when the lowboy vehicle became immobilized on an excessively steep crossing, and was struck by the passenger train.

- The lowboy truck was being led by a pilot vehicle whose operator did not recognize that the crossing was impassable for a lowboy vehicle, as there was no advanced signage or warning system.

- Although the truck was on the crossing for about seven minutes, the urgency of alerting railway authorities and stopping approaching trains was not recognized.

- Emergency information signage at the crossing was not sufficiently conspicuous or compelling to be noticed by the vehicle operators.

- Inspection protocols by the railway, the road authority, and the regulator were insufficient to identify crossings with profiles that could not be negotiated by lowboy vehicles.

3.2 Findings as to risk

- In the absence of a protocol to identify excessive crossing profiles, there is no way to restrict their use by low-clearance vehicles and trailers.

- With thousands of low-clearance trailers on Canadian highways, the lack of standardized signage to identify steep crossing profiles increases the likelihood that trucks will continue to become immobilized at crossings.

- Training of truck drivers is insufficient to ensure drivers will alert railway authorities in the event their vehicle becomes immobilized on a railway crossing.

4.0 Safety action

4.1 Action taken

4.1.1 Investigation of Crossing Accident at Pincourt, Quebec

As a result of a Board investigation into a crossing accident involving an immobilized tractor-trailer in Pincourt, Quebec, in December 2007 (TSB report R07D0111), the Board recommended that:

Transport Canada conduct safety assessments of level crossings on the high-speed passenger rail Québec–Windsor corridor and ensure that defences are adequate to mitigate the risk of truck/train collisions.

Transportation Safety Recommendation R09-01, issued April 2009

Assessment/Reassessment rating: Satisfactory intent

In response to this recommendation, Transport Canada (TC) recognizes the risks associated with the use of long and heavy vehicles at grade crossings and has requested the railways conduct safety assessments at all grade crossings along this corridor. TC's response to this recommendation was assessed as having Satisfactory Intent.

In the Pincourt investigation, there were also issues identified related to emergency signage, and the Board recommended that:

Transport Canada implement standards to improve the visibility of emergency contact signage at railway crossings in Canada.

Transportation Safety Recommendation R09-02, issued April 2009

Assessement rating: Satisfactory intent

In response to this recommendation, TC accepted the need for standards to improve the visibility of emergency contact signage at railway crossings and is currently investigating the implementation of such signage. TC's response to this recommendation was assessed as having Satisfactory Intent.

4.1.2 TSB Rail Safety Advisory

On 04 December 2008, TSB Rail Safety Advisory 08/08, Low Clearance Road Vehicles on CN's Kingston Subdivision, identified an ongoing risk of collision and derailment for freight and passenger trains involving low-clearance vehicles. The letter stated that "In view of the freight and passenger rail traffic density on this (the Kingston Subdivision) high speed multi-track corridor, it is highly likely that accidents involving low-clearance trailers will continue to occur on a frequent basis. TC may wish to take immediate action to assess the ongoing risk presented by low-clearance vehicles at all level crossings with steep vertical profiles and take appropriate action to ensure safe railway operations."

4.1.3 Transport Canada

TC's response to Rail Safety Advisory 08/08 referred to a number of activities conducted since late 2002 in response to a number of accidents on the Kingston Subdivision. These activities include:

- An amendment to the proposed grade crossing regulations to include a requirement for a safety review by a responsible authority, within a reasonable time, of any report or evidence of "the front, rear or underside of a vehicle making contact with the crossing surface or the surface of a road approach within 30 metres of the rail."

- The Canadian Road/Railway Grade Crossing Detailed Safety Assessment Field Guide, published by TC in 2005, includes the instruction to inspect the crossing surface for physical signs that road vehicles have had problems clearing the crossing.

- Since 2003, Canadian National (CN) and TC have closed four crossings and improved the alignment and grade of two crossings that were on the list of 116 grade crossings on the Kingston Subdivision with a gradient equal to or greater than 5 per cent.

- A study to assess the potential of light detection and ranging (LiDAR) technology as a tool for creating an electronic inventory of grade crossings, including geometric characteristics, was conducted.

In addition, TC compiled a list of road authorities on the Kingston Subdivision having crossings with one or the other approach gradient greater or equal to 5 per cent as indicated in its crossing database (IRIS) and a list of non-public crossings on the Kingston Subdivision with an approach gradient greater than or equal to 5 per cent. In June 2009, TC sent a letter to each of these road authorities. The letter alerts the road authorities that such crossing gradients may pose clearance problems for low-clearance vehicles or trailers, and requests the road authority to undertake the following activity:

- Confirm that the approach gradient is at or above 5 per cent.

- If so, install signage to alert motorists to the gradient and/or hazard to low-clearance vehicles.

- Report back on action taken.

In July 2009, TC sent the list of non-public crossings on the Kingston Subdivision with an approach gradient greater than or equal to 5 per cent to CN. The letter asks CN to:

- Note if the railway, in its ongoing crossing inspections, has identified any discrepancies with the gradients provided in the TC database.

- Identify what actions (for example, communications with the landowner, installation of signage, reprofiling of the crossing approach gradient) have been taken to mitigate the risk associated with the crossing approach gradients at these locations.

- Report back on action taken.

4.1.4 United Counties of Leeds and Grenville

The United Counties of Leeds and Grenville installed signage on the approach and in the vicinity of the Quabbin Road crossing (see Photos 7a and 7b), alerting low-clearance vehicle operators to the risk of becoming immobilized on the crossing surface.

4.2 Action required

4.2.1 Standardization of low-clearance vehicle warning signs

In 2002, following a grade crossing accident at Coronation Boulevard in the city of Kingston, Ontario (TSB report R02T0149), TC committed to working with road and railway authorities to identify crossing locations suitable for use by heavy/large vehicles, to propose the adoption of a standardized low ground clearance warning sign, and to conduct research into lowboy trailer clearances. Yet, when the Quabbin Road crossing accident occurred, action towards the identification of locations suitable for use by heavy/large vehicles, and the establishment and installation of standardized signs to warn drivers of crossings that present a potential hazard for low-clearance vehicles had not progressed.

Following the Quabbin Road accident, TC has taken action to support the timely communication and implementation activities to improve crossing safety. The June 2009 letter to road authorities on the Kingston Subdivision alerts them to crossings that may have troublesome approach gradients, encourages them to confirm the approach gradient, and where necessary, to install signage to alert motorists to the gradient and/or hazards to low-clearance vehicles. The July 2009 letter to CN requested the railway to report back on its most recent private crossing inspections, on its communications with property owners, and on its corrective actions. While these letters do not consider crossings with approach gradients less than 5 per cent that can also be problematic to low-clearance vehicles, these actions demonstrate a proactive response.

However, with more than 10 000 low ground clearance vehicles on the road,Footnote 10 and with the presence of grade crossings with non-standard gradient approaches on main-line track in high-density corridors, the risk for accidents involving vehicles with low-clearance designs continues. When crossing accidents involve immobilized trucks and high-speed passenger trains or trains carrying dangerous goods, the consequences can be catastrophic.

Professional truck drivers are expected to know the limits of their equipment. Some modern trucks have been equipped with hydraulic systems that allow the operator to increase ground clearance. However, drivers expect that unusual road hazards that affect safety will be identified, including but not limited to low overpasses, high bumps and sharp curves in the road. Drivers expect hazards to be appropriately marked with advance warning signs to identify the risk and to suggest suitable driver action. Advance warning signs have been recently installed at two crossing accident locations with non-standard gradient approaches (that is, Coronation Boulevard and Quabbin Road) on the Kingston Subdivision.

To date, TC's efforts have increased awareness of the risks of non-standard gradient crossings and the need to provide advance warning to drivers of low-clearance vehicles. However, the absence of a national signage standard to warn low-clearance vehicles can lead to inconsistent signage. Standard, nationally recognized signage would provide a defence to alert oncoming drivers to the risk of proceeding over the crossing. Therefore, the Board recommends that:

Transport Canada work with the provincial governments to expedite the implementation of a national standard for low ground clearance advance warning signs at railway crossings.

Transportation Safety Recommendation R09-04

Assessment Rating: Satisfactory intent

4.3 Safety concern

4.3.1 Driver awareness of requirements to Alert Railway Authorities during grade crossing emergency situations

There have been a number of recent initiatives to enhance driver awareness of grade crossing risks. Operation Lifesaver has produced education modules specifically designed to educate professional drivers on grade crossing safety, including instructions on what to do in the event their vehicle is disabled on a crossing. Class 1 railways have added information to their websites to inform vehicle operators of the appropriate actions when they require assistance at grade crossings. TC is currently investigating the implementation of emergency contact signs which have improved visibility.

While it is encouraging that the regulator and railway industry have initiated various activities to increase driver awareness of grade crossing risks, the Board is concerned that, unless trucking companies and drivers operating low ground clearance vehicles are educated on grade crossing emergency situations, including when and how to alert railway authorities, grade crossing collisions involving trains and immobilized vehicles will continue to occur.

This report concludes the Transportation Safety Board's investigation into this occurrence. Consequently, the Board authorized the release of this report on .