Steering gear failure and grounding

Product/chemical tanker Chem Norma

Morrisburg, Ontario

The Transportation Safety Board of Canada (TSB) investigated this occurrence for the purpose of advancing transportation safety. It is not the function of the Board to assign fault or determine civil or criminal liability. This report is not created for use in the context of legal, disciplinary or other proceedings. See Ownership and use of content. Masculine pronouns and position titles may be used to signify all genders to comply with the Canadian Transportation Accident Investigation and Safety Board Act (S.C. 1989, c. 3).

History of the voyage

On 29 May 2018, the Marshall Islands–flagged product/chemical tanker Chem Norma (IMO 9486192, Figure 1) was proceeding upbound the St. Lawrence Seaway, carrying a cargo of 11 119 tonnes of alkylate (UN1268) bound for Sarnia, Ontario. The bridge team at the time consisted of the master, a pilot, the third officer, a helmsman, and a lookout.

At 0415,Footnote 1 as the helmsman was steering the vessel in follow-up modeFootnote 2 and applying small corrections to maintain the vessel on a course of 238° gyro, the rudder unexpectedly went hard over to starboard while the vessel was steaming at a speed of 11 knots.Footnote 3 At that time, the steering gear system was operating on System No. 1 with the No. 2 steering pump running.Footnote 4 The vessel sharply veered to starboard and exited the buoyed channel, entering the charted anchorage area off Morrisburg, Ontario. The master immediately stopped the main engine.

The master changed the steering mode over to non-follow-up mode 23 seconds after the malfunction, however, the steering gear did not respond and remained hard over to starboard. The pilot ordered the main engine to full astern, and the master switched the steering control system from No. 1 to No. 2. Control of the steering gear was regained at that time. The master brought the rudder to hard-a-port while the vessel was still in non-follow-up mode, and the main engine was ordered to full ahead. Despite these actions, the Chem Norma ran aground on the Seaway's northern bank, outside the anchorage area, coming to a stop 2 minutes and 25 seconds after the steering gear malfunction.

Approximately 650 tonnes of cargo were transferred from tanks No. 2, 3, and 4 starboard to tank No. 6 port, and the vessel was refloated on 03 June 2018 with the assistance of 3 tugs and the managed rise of the St. Lawrence Seaway's water levels.Footnote 5 The vessel sustained minor damage to its hull,Footnote 6 and major damage to its propeller and rudder. No injuries or pollution were reported.

Steering control system

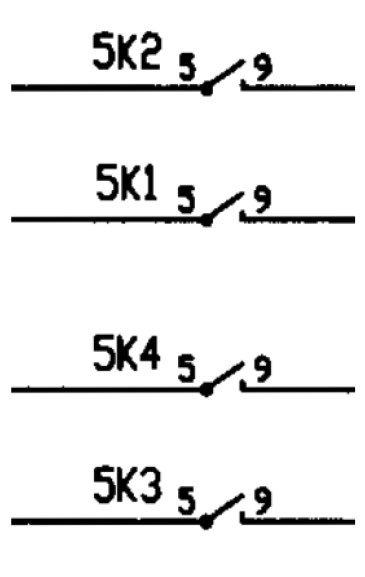

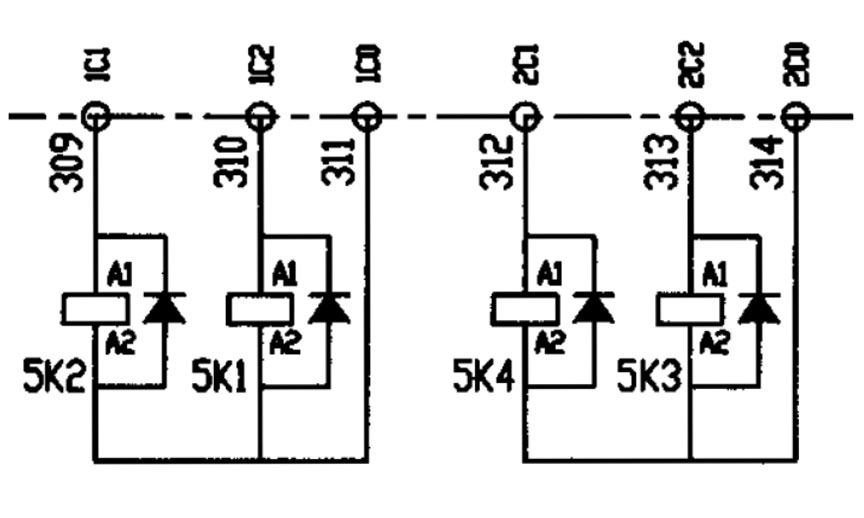

The steering system on the Chem Norma comprises 2 distinct electronic controllers, System No. 1 and System No. 2, both of which directly control, via electromechanical relays, the solenoid-operated hydraulic directional control valves that actuate the steering gear rams. These control relays are designated as 5K1, 5K2, 5K3, and 5K4 in the vessel's technical diagrams.

Relay 5K3 energizes the solenoid of the hydraulic directional control valve that commands the rudder to starboard when steering pump No. 2 is in use, independently of the electronic controller in use. Relay 5K3 is a widely available 24 volts direct current (VDC) plug-in relay of the double pole double throw type, rated for 12 amperes at 28 VDC.

TSB examination of control relays

The TSB conducted an examination of and a failure analysis on control relays 5K1, 5K2, 5K3, and 5K4. Signs of heat damage were observed in the vicinity of the contacts being used (contacts 5 and 9). The contacts themselves were extensively deteriorated and showed clear signs of electrical arcing. Scanning electron microscopic (SEM) and spectrographic examinations of contacts 5 and 9 were also performed on the 4 relays. Although no obvious evidence of welding action could be seen on the contacts, spike-like structures and craters on relay 5K3 due to loss of the base silver-nickel (AgNi) alloy material and subsequent re-solidification of molten metal suggest a probable mechanical hanging of contacts 5 and 9. All of the relays examined showed signs of damage due to electrical arcing, albeit not as pronounced as the damage observed on relay 5K3.

Effect of voltage and current surges on control relays

Relay contacts are subject to large voltage and current surges when switching inductive loads, such as to direct-current solenoids. When the contacts open, it is important that surges be absorbed (e.g., with a diode) to protect the contacts. The Chem Norma's steering control electrical system did not have provisions or countermeasures to protect the control relays' contacts from voltage and current surges (Figure 2); however, the control relays' power coils were protected by a diode connected in parallel to them (Figure 3).

Although relays 5K1, 5K2, 5K3, and 5K4 are theoretically compatible for use with the 24 VDC/30 watt solenoids they were controlling, this particular model of relay was designed as a general-purpose type C transfer contact relay. This type of relay is not suited for voltages that exceed its 28 VDC rating, which are generated when the contact is broken by the counter-electromotive force inherent to the inductive load created by the solenoid. Other types of relays are specifically designed to better handle the severe conditions produced by these inductive loads.

As per the vessel's computerized planned maintenance system, at the time of the occurrence some of the relays, including 5K3, had been in service for 16 months, which is within their renewal range of 24 months. The day after the grounding of the vessel, the company changed the renewal periodicity from 24 months to 12 months for relays 5K1, 5K2, 5K3, and 5K4. The investigation also revealed that the crew was sometimes recording the “relays replacement” work order in the planned maintenance system as completed, even when only a partial replacement of the relays had been carried out. This meant that some relays were being kept in service after their recommended lifespan and were not being identified as such.

In this occurrence, although the precise cause for the temporary failure of the Chem Norma's steering gear control system could not be determined, a plausible scenario is a temporary mechanical hanging that held contacts 5 and 9 closed on relay 5K3, triggering a hard-a-starboard order on the steering gear.

Safety action taken

On 27 July 2018, the TSB sent Marine Safety Information Letter 04/18 to the company (ASM Maritime B.V.), with a copy to Transport Canada, Marshall Islands, Liberia (which is the Flag State Authority for 3 of the Chem Norma's sister ships), Nippon Kaiji Kyokai (ClassNK), and Tokyo Keiki Inc. The safety information letter outlined the results of the examination and failure analysis performed on control relays 5K1, 5K2, 5K3, and 5K4, emphasizing the poor condition of relay 5K3 and the unsuitability of this particular model of relay to handle the severe conditions produced by inductive loads such as solenoids. The letter also identified the possible source of the failure of the steering gear system and warned the company that the same loss of steering control might occur on any of the Chem Norma's 4 sister vessels fitted with a similar steering gear control arrangement.

Following this occurrence, the vessel's Flag State Authority, the Marshall Islands, recommended that the vessel owner review procedures in the company's safety management system regarding emergency steering and loss of steering, with a focus on loss of steering in a narrow waterway and loss of steering with hazards in close proximity to the planned route. The vessel owner also contacted the steering system manufacturer to request a type of control relay that is designed to better handle the severe conditions produced by the inductive loads found in the vessel's steering system.

This report concludes the Transportation Safety Board's investigation into this occurrence. The Board authorized the release of this report on . It was officially released on .