Tug Girding and capsizing

Tug North Arm Venture while towing the barge North Arm Express

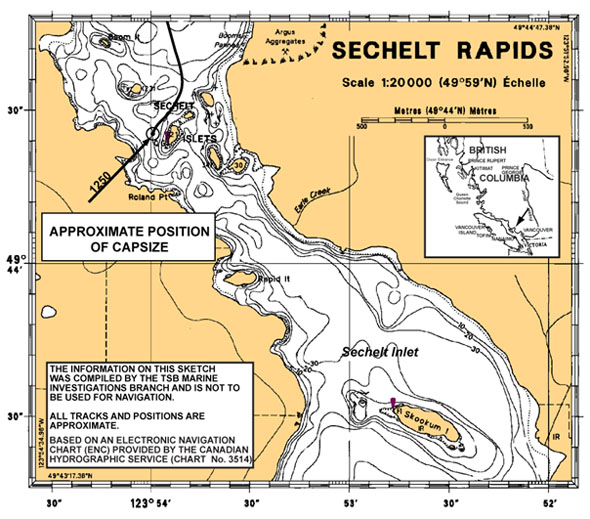

Entrance to Sechelt Rapids, British Columbia

The Transportation Safety Board of Canada (TSB) investigated this occurrence for the purpose of advancing transportation safety. It is not the function of the Board to assign fault or determine civil or criminal liability. This report is not created for use in the context of legal, disciplinary or other proceedings. See Ownership and use of content. Masculine pronouns and position titles may be used to signify all genders to comply with the Canadian Transportation Accident Investigation and Safety Board Act (S.C. 1989, c. 3).

Summary

On 19 July 2009, the tug North Arm Venture was towing the barge North Arm Express, loaded with fuel and deck cargo, from Toba Inlet to Sechelt Inlet. The tug girded and capsized at approximately 1250 Pacific Daylight Time while making a turn to port at the entrance to Sechelt Rapids. The four crew members on board were rescued, with two suffering minor injuries. The overturned tug and barge were subsequently towed by the tug Sea Imp IX to Killam Bay.

Ce rapport est également disponible en français.

Factual information

Particulars of the vessels

| Name | North Arm Venture | North Arm Express |

|---|---|---|

| Registry/Licence number | 331902 | 331168 |

| Port of registry | Vancouver, British Columbia | Vancouver, British Columbia |

| Flag | Canada | Canada |

| Type | Tug | Barge |

| Gross tonnage | 35.46 | 786 |

| LengthFootnote 1 | 12.80 m | 52.43 m |

| Draught | Forward: 1.75 m Aft: 1.9 m |

Forward: 1.2 m Aft: 2.1 m |

| Built | 1970 | 1969 |

| Propulsion | 2 x 320 hp Detroit diesel engines | nil |

| Cargo | nil | 5 empty cement carriers, 3 trucks, 370 156 litres of diesel fuel and gasoline in bulk |

| Crew | 4 | nil |

| Registered Owner and Manager | North Arm Transportation, Ltd. | North Arm Transportation, Ltd. |

Description of the vessels

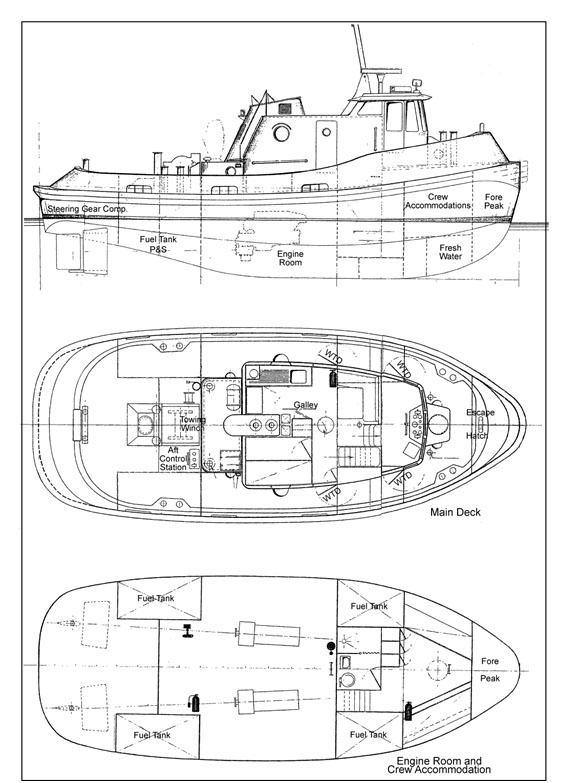

The North Arm Venture is a conventional coastal tug of steel construction (see Photo 1 and Appendix B). The navigation bridge is located on the fore part of the main deck. There is a conning position in the wheelhouse with steering and engine controls, another on the wheelhouse top with similar controls—allowing an unobstructed view in all directions—and a third steering position alongside the towing winch. All three positions are equipped with an abort switch for the tow line.

The tug has two propellers in Kort nozzlesFootnote 2 and two rudders. On the main deck is a galley, a mess area and a cabin for the master. The deckhouse is fitted with watertight doors port and starboard. One deck below and forward in the forecastle is a cabin for the mate and two deckhands. An escape hatch is located on the deckhead of the forecastle; this exits just forward of the navigational bridge.

The North Arm Express is a steel barge fitted with a reinforced flat deck and bow ramp. The barge can carry petroleum products in tanks within the hull, and general cargo on deck. The barge has a pump room and a fuel transfer manifold.

History of the voyage

The North Arm Venture departed Vancouver, British Columbia, on 17 July 2009, bound for a number of locations. On 18 July 2009, the North Arm Venture left Toba Inlet, British Columbia, at 2100.Footnote 3 The tug, with a crew of four,wastowing the barge North Arm Express, heading for Sechelt Inlet, British Columbia. Cargo on board the North Arm Express included 370 156 litres of diesel fuel and gasoline in bulk, 5 empty bulk cement carriers and 3 trucks on deck.

As travelling time from Toba Inlet would have seen the tug arrive about an hour after slack water, the decision was made to "run slow" to arrive at Sechelt Rapids at the following slack water in order to transit at low tide slack water, predicted at 1254 on July 19.

The master, mate, and crew were working a watch system of six hours on/six hours off. The master and deckhand No. 1 worked from 0600 to 1200 and 1800 to 2400, whereas the mate and deckhand No. 2 worked from 0000 to 0600 and again from 1200 to 1800. There were no indications that fatigue was a factor.

On July 19 at 0600, the master came on watch when the tug was abeam Scotch Fir Point at the entrance to Jervis Inlet, approximately 16 miles from Sechelt Rapids. The tug and tow proceeded at slow speed, planning to arrive at the Sechelt Rapids at low tide slack water. At 1200, the tug and tow were 2.8 miles from Sechelt Rapids, abeam Egmont Point, when the master handed over the watch to the mate. The master and deckhand No. 1 subsequently went down to the galley for lunch, after which deckhand No. 1 went forward to the forecastle to rest.Footnote 4

At 1215, the master returned to the wheelhouse top to provide the mate with advice during the transit through the narrows.

At 1235, the tow line was shortened to approximately 19 mFootnote 5, including an 11 m bridle, to enhance manoeuvrability for the transit through the narrows.

At 1246, the master took over the helm and increased power to half ahead to proceed into the ebb current. The ebb current was still running, estimated at 1 to 2 knots, but the master noticed it was diminishing. As they approached the narrows the barge experienced a sheer to starboard. The master commenced his alteration to port, from a heading of 220° True (T) to a heading of approximately 136° T. The barge, however, did not follow through the turn and continued on its course.Footnote 6 To regain control of the tow, the master then sought to reposition his tug ahead of the barge by applying starboard helm. This manoeuvre was unsuccessful, and the barge overtook the tug.

Pulled starboard by the force from the towline, the tug girded on its starboard side (see Photo 2) and quickly capsized at approximately 1250 in position 49° 44.5′ N, 123° 54′ W.

As the vessel rolled over, the master, mate, and deckhand No. 2 moved to high points on the tug until it was evident that the tug was going to capsize at which time they dove or jumped into the water. Due to the swiftness of the capsizing, neither the master nor the mate was able to alert the crewmember below deck or transmit a distress call. The master subsequently climbed onto the overturned tug, whereas the mate and deckhand No. 2 climbed onto the barge. Deckhand No. 1, who had been sleeping in the forecastle, was thrown from his berth, eventually landing on the deck head; however, he was able to escape via the forward open escape hatch, which had been left open to circulate fresh air. He was then assisted onto the barge by a local kayaker, who had paddled out after watching the event from shore.

In response to smoke from the tug's engineFootnote 8, the Sea Imp IX—a tug that was secured alongside in Earls Creek, less than a mile away—got underway at 1255. After arriving on the scene, Sea Imp IX towed both the tug and barge to Killam Bay. Deckhand No. 1, meanwhile, was transported by workboat and ambulance to a local hospital and released the same day.

The North Arm Venture was righted the next day and towed to Vancouver.

Area of the occurrence

Sechelt Rapids, known locally as Skookumchuck Rapids, are located at the entrance of Sechelt Inlet.Footnote 9 The rapids extend over an area approximately 1000 m long and 500 m wide. Tidal streams within the rapids can reach 16 knots during large tides.

The strongest ebb stream occurs just west of Sechelt Islets light (see Photo 3), with a strong cross-channel set towards the west-northwest. A large back eddy occurs to the north of the light, and whirlpools form close to the light.

Although the preferred time to transit Sechelt Rapids is high tide slack water, they are also navigable at low tide slack water. However, it is hazardous for any vessel to attempt to navigate Sechelt Rapids except at or near these times. Low-powered vessels, or those that answer the helm sluggishly, can find themselves spun about or set upon the west shore.

Weather and current information

The predicted time of low tide slack water at Sechelt Rapids was 1254. However, meteorological conditions, such as barometric pressure changes and prolonged winds, can cause differences between the predicted and observed tides.Footnote 10 The local Environment Canada weather station in Sechelt at 1300 hours indicated light winds of 6 km/h from 020 ° T. Local weather was reported to be clear and sunny with a temperature of 21 °C .

Closure of watertight doors and hatches

Due to warm temperatures, the crew occasionally left some of the tug's watertight closures open, to allow fresh air to circulate. At the time of the capsizing, several of these were not secured for sea, including: the vessel's port side main deck watertight door, two engine room skylight hatches, the master's porthole, and the forward escape hatch located in the forecastle's deckhead.

Safety management

International safety management code

The objectives of the International Safety Management (ISM) Code adopted by the International Maritime Organization (IMO) are to ensure safety at sea, prevent human injury or loss of life, and avoid damage to the environment. This is done by implementing safe practices in ship operations and promoting a safe working environment, by establishing safeguards against all identified risks and by continuously improving the safety management skills of personnel ashore and aboard ships.Footnote 11

The ISM Code, which applies to all SOLAS conventionFootnote 12 vessels over 500 gross tonnes or carrying passengers, requires companies and vessels to develop and implement a Safety Management System (SMS). Once a company has complied with the requirements of the ISM Code, it is issued a Document of Compliance (DOC) by a recognized institution or organization, such as a classification society or the government of the flag state.

The functional requirements of an SMS include:

- a safety environmental protection policy;

- instructions and procedures to ensure safe operation of vessels and protection of the environment;

- defined levels of authority and lines of communication between, and among, shore- and vessel-based personnel;

- procedures for reporting accidents and non-conformities;

- procedures to prepare for, and respond to, emergency situations; and

- procedures for internal audits and management reviews.

A company's SMS should include ship-specific elements that recognize the inherent operations and configurations unique to each vessel the company operates. Accordingly, the SMS includes procedures to prepare for and respond to emergency situations that could be expected to arise on a particular vessel.

In October 2002, although not required to do so by regulation, North Arm Transportation voluntarily adopted the ISM Code for part of its domestic fleet of tugs and barges. The company's SMS, which had been certified by Lloyd's Register as being compliant with the ISM Code, had last been updated in May 2009. The North Arm Venture and North Arm Express did not form part of the SMS audited by Lloyd's Register.

Domestic SMS (DSM)

A domestic SMS (DSM) is a voluntary safety management system that is based on the ISM Code, but adapted for use in the Canadian domestic fleet with the objective of encouraging domestic operators to develop a safety management system as a tool to enhance safety and assist operators in complying with the modernized Canada Shipping Act, 2001.Footnote 13 DSM forms part of a two year pilot project, launched in 2009 by Transport Canada in the west coast tug and barge sector.Footnote 14 The goal of the DSM initiative is to "provide a Canadian domestic standard for the safe management and operation of vessels, and for pollution prevention."Footnote 15

Similar to the ISM Code, the DSM guidelines require that potential risks and harmful practices be identified, and that appropriate safeguards be implemented.

For the duration of the pilot project, Transport Canada is responsible for auditing each company's safety management system against the DSM guidelines.

As a participant in the pilot project, North Arm Transportation developed and implemented a Safety Management System that was structured according to the DSM guidelines and which was reviewed by Transport Canada in November 2008, before the launch date of the pilot project. The manual, which formed part of the company's DSM, included the following components:

- Policy statement and company organization;

- Safety and environmental policy;

- Drug and alcohol policy;

- Shipboard plans and procedures;

- Emergency preparedness and contingency planning;

- Vessel maintenance;

- Reporting of accidents, hazardous occurrences and non-conformities;

- Audits and reviews.

Neither the company's SMS nor its DSM manual contained specific measures dealing with a possible girding scenario.

Vessel certification

On 27 March 2009, Transport Canada issued a Safety Inspection Certificate (SIC) to the North Arm Venture. The vessel held a valid Domestic Safety Management certificate, a Radio Inspection certificate, and a Minimum Manning Certificate.

Personnel certification and experience

All crew held valid certificates for the vessel and type of voyage undertaken.

The master had over 20 years of experience aboard tugs. He had been with North Arm Transportation for the last 15 years, and had been working as a master for five years. He held a valid Master 500 Gross Tonnage, Near Coastal certificate, issued 30 June 2009.Footnote 16 The master had transited the Sechelt Rapids at least 50 times. During his career he had never aborted a tow under operational circumstances.

The mate held a valid Watchkeeping Mate certificate, issued 27 July 2008. Although this was his first transit at the helm through the rapids, he had transited the Sechelt Rapids numerous times as a deckhand.

Deckhand No. 1 held a valid Supervisor of an Oil Transfer Operation certificate, issued 12 December 2007.

Both deckhands held marine emergency duties certificates (A1, B1, B2) and valid first-aid certificates.

Damage

The vessel suffered no hull or structural damage. However, electronic navigation equipment, wiring, and engineering machinery were damaged beyond repair.

There was a small release of diesel during the righting of the vessel. This was contained and later removed. A subsequent shoreline assessment conducted by the Coast Guard found no traces of marine pollution.

Lifesaving equipment

The North Arm Venture carried all required emergency equipment, including two four-person liferafts with a hydrostatic release. When the tug capsized, both releases worked and both liferafts deployed; however, one liferaft became tangled in the rigging and did not float free.

The tug's emergency position indicating radio beacon (EPIRB) did not deploy, but remained in its bracket. When the vessel was righted the following day the EPIRB did release and transmitted a signal.

The tug also carried personal floatation devices (PFDs) as required by the company SMS. None of the crew on deck wore PFDs at the time of the capsizing.

Towing equipment

The Hull Construction Regulations Footnote 17 deal specifically with the equipment requirements for towing operations. The requirements for the towing winch include an abort switchFootnote 18 to release tension on the towline. The towing requirements also include tow pins,Footnote 19 a hook, and a means of two-way communication between the steering position and the towing winch.

The North Arm Venture was fitted with an abort switch that could be activated from any of the vessel's three steering positions and could be reset after activation to stop the full length of the tow line from running off the drum (see Photo 4).

Deckhand No. 2, whose duty was to stand by the towing winch and release it in case of an emergency, was on the bow prior to the capsizing where he could be in direct communication with the master.

Girding

Girding is defined as a situation where a vessel experiences athwartship forces from its towline. This situation can lead to a capsizing or foundering. It is considered one of the most hazardous situations a tug may encounter and the risk of girding is often present during towing operations. In some circumstances, however, girding forces may be used as part of normal or standard operating procedures.Footnote 20

The risk of girding increases as the distance between the tug and the barge is reduced, which is often done to improve manoeuvrability. Often, when the towline is shortened, the vertical angle of the towline will increase, rendering the tow pins ineffective.

As a result of several investigationsFootnote 21 into the girding and subsequent capsizing of towboats, Transport Canada issued Ship Safety Bulletin (SSB) 13/1994, "Towboats – Dangers Associated with Girding." The safety bulletin advises owners and operators of the hazards associated with towing operations. The bulletin points out the dangers of girding and strongly urges masters to manage the risk by adopting any practical

measures that might prevent their vessel from being placed in a girding situation. TSB statistics indicate that, since 1999, there have been three near-capsizings and eight capsizings as a result of girding (including this occurrence), resulting in four fatalities.Footnote 22

At the time of the occurrence, neither the company's SMS, nor the DSM manual carried by the North Arm Venture, included information or precautions on girding. Both documents did include a pre-departure checklist, which specifies testing the abort switch.

In this occurrence, the abort switch had been tested prior to departure and was readily available to anyone at either steering station and at the towing winch.

Analysis

Transit through Sechelt Rapids and girding

The practice of good seamanship dictates that mariners make speed and course alterations according to environmental and navigational challenges that arise during the course of a voyage. These include prevailing conditions of tide, current, sea room, traffic, and weather. Precautions must also be taken before any voyage or transit. For example, the crew should be aware of available power and required speed, they should be properly positioned to perform emergency duties, wear the appropriate personal protective equipment and close any watertight openings during transits through restricted or rough waters.

In this occurrence the master, who was on top of the wheelhouse to aid the mate in the transit, had the abort switch within his reach. From this position, he observed the tidal conditions to assess the last ebbing of the current. As the North Arm Venture approached the narrows, the barge experienced a sheer to starboard. The master commenced the port turn; the barge, however, did not follow. This was due to the residual ebb tide acting on the barge's port side, which countered the pulling force of the tug.

In order to pull the barge through the narrows successfully, good seamanship would have dictated waiting for slack water before making the attempt. Otherwise, given the conditions, the tug would have had to exert sufficient force to overcome the momentum of the barge in the prevailing tidal current. This would have meant entering the rapids with more reserve power (i.e. entering at a reduced speed to keep the barge from building way), followed by a more gradual turn to port.

In this case, however, shortly before entering the rapids, the master increased power to half ahead. As the tug began its course alteration to port, it could not counteract the effect of the tidal current on the barge and pull it through. Moreover, as a result of the angle forming between the tug and the barge, the tug would have required more power to bring the barge around. As a result, the barge was not pulled directly through the rapids, and the tug was no longer in front.

With the tug on a heading of approximately 136° True (T), and the barge on approximately 220° T, and given the shortened towline, the barge quickly covered the distance to the tug's stern at an approximate right angle. Although the shortened towline was intended to improve manoeuvrability, with the vessels in this position, it pivoted such that its force was acting athwartships on the tugboat, and no longer directly behind it. This resulted in the tug capsizing to starboard.

A crew member was not positioned immediately next to the winch brake, nor were crew members on deck wearing PFDs. Although the absence of these precautionary measures were not contributory factors, good seamanship dictates that such measures be taken when entering a hazardous area in order to reduce the operational risks. Furthermore, given that the tug and barge remained connected, the watertight openings could not be conclusively identified as causal to the capsizing; however, the absence of this precautionary measure precluded any possibility of the tug righting itself.

Response to the girding

Girding is when a vessel experiences athwartship forces from its towline, which can lead to capsizing. It can be caused by the tow (i.e., a ship or barge) turning independently and too quickly away from the tug. The generally accepted strategy to alleviate the risk of capsizing is to either slack the towline, or reposition it such that the pull is over the stern of the tug.

At the time of the occurrence, the company did not have procedures to guide the master in the event of an unintentional girding or capsizing scenario. Mariners who find themselves in a position of risk for which they have no direction (e.g., in the form of procedures or prior experience) may opt for a course of action that does not effectively mitigate the risk.

Once it became apparent that the tow was not responding, and that the tug was being girded, three options were available to the master:

- Abort the tow line (completely or in part)

- Attempt to regain control

- Allow the tug to be towed stern first by the barge.

Each of these options had its own risks.

By aborting the tow, or allowing the tug to be towed stern first, the master stood to eliminate the risk of girding. However, he risked a grounding, a loss of cargo, and environmental damage.

By electing not to abort, he was attempting to regain control of the barge, and prevent any loss of cargo or environmental damage. However, this involved a risk of girding or capsizing, along with the total loss of the tug and possible damage to the barge.

It is known that, when people find themselves in a situation where they must solve a problem to which no rules apply and a new solution or plan must be formulated, there is a tendency to frame the problem as a choice between gains and losses. With respect to losses, people are biased toward choosing the risky loss—even if it is potentially more disastrous—rather than the certain loss.Footnote 23

In this occurrence, although the tug master had several decades of experience, he lacked direction from the company in the form of procedures to deal with girding. He therefore had to analyze the situation as it was unfolding and choose an immediate course of action based on his own experience, which had never involved aborting a tow. By electing not to abort, he selected the option that allowed him the possibility of quickly regaining control of the tow, even though the severity of the possible consequences—girding and capsizing—were significantly greater than opting to abort.

In the absence of procedures or guidelines, the master lacked important information that could have helped him decide how to respond to the girding situation.

Risk identification within SMS

Girding is a well-recognized phenomenon in the towing industry. Deck officers receive instruction on how to deal with it, including how to manipulate the forces involved for operational purposes. However, when girding is unintentional, it can be extremely hazardous, with possible consequences including foundering and/or capsizing.

In this occurrence, the operator considered girding to be so common that it assumed masters and mates would have previous experience with it and could be expected to know what to do. As a result, neither the SMS nor the DSM contained specific procedures, instructions or guidelines relating to unintentional girding. Furthermore, this absence was not identified in the reviews conducted by the external auditors (Lloyd's Register and Transport Canada).

It is likely that this lack of procedures impacted the master's decision making. However, the absence of a procedure or guideline in itself is not necessarily a sign of a deficient SMS. Rather, once a risk or hazard is identified—in advance or following a hazardous occurrence or accident—a well-functioning SMS mitigates it through corrective action. This highlights the importance of thoroughly and objectively identifying key hazards when developing, implementing, revising and auditing a SMS. With respect to a hazard as common and potentially severe as unintentional girding, its absence from the SMS is a deficiency, one which may leave crews without procedures to address such hazards.

Findings

Findings as to causes and contributing factors

- The transit through Sechelt Rapids began prior to slack tide and, as a result, the barge came under the influence of the ebb tide, causing it to shear to starboard.

- The attempt to regain control of the barge was unsuccessful due to an insufficient reserve of power on the tug.

- The North Arm Venture capsized when the shortened towline pivoted athwartships; its force, then acting transversely, rapidly overcame the tug's righting ability.

- The absence of procedures or guidelines on girding left the master without important information to aid in his decision-making.

Findings as to risk

- Without a thoroughly developed, implemented, and audited SMS, crews may be left without procedures to address key hazards.

- In the absence of precautionary measures—such as the positioning of the crew, the wearing of personal floatation devices and the closing of watertight openings—crews will be exposed to a level of risk that is not as low as reasonably practicable.

Safety action

Action taken

As part of the pilot project, Transport Canada discussed the occurrence with each of the five participating companies and with the Council of Marine Carriers. Procedures for imminent capsize response were developed for their consideration and insertion into their Domestic Safety Management System (DSM) manuals where appropriate.

In September 2009, Transport Canada observed a Lloyd's Document of Compliance audit and met with North Arm Transportation, Ltd. to discuss the results of the company's internal investigation of the capsizing.

North Arm Transportation replaced its Domestic Safety Management manual with the company's existing safety management manual used for the voluntary adoption of the ISM Code. Transport Canada reviewed the manual and determined that it met the requirements of the DSM Guidelines. The North Arm Transportation vessels participating in the pilot project now use the company's ISM Code safety management manual.

In addition to its own investigation, the company took the following action:

- A safety memo was issued to all North Arm crews concerning the girding of the North Arm Venture.

- Emergency response plans were amended to include guidelines on what to do in the event of a capsizing.

- A company-wide meeting was held to discuss the occurrence with the crews. As a result of these discussions, the company's navigation procedures were amended to include further instruction on planning and hazard analysis, as well as a narrative description of girding and the actions to prevent or mitigate such incidents.

- A review of marine casualties was carried out to determine if any scenarios should be considered for inclusion within its emergency procedures.

This report concludes the Transportation Safety Board's investigation into this occurrence. Consequently, the Board authorized the release of this report on .