Grounding and constructive total loss

the bulk carrier Alcor

Traverse du Nord, St. Lawrence River

AND

Subsequent near-collision between

the tanker Eternity and

the container ship Canmar Pride

The Transportation Safety Board of Canada (TSB) investigated this occurrence for the purpose of advancing transportation safety. It is not the function of the Board to assign fault or determine civil or criminal liability. This report is not created for use in the context of legal, disciplinary or other proceedings. See Ownership and use of content. Masculine pronouns and position titles may be used to signify all genders to comply with the Canadian Transportation Accident Investigation and Safety Board Act (S.C. 1989, c. 3).

Summary

On 09 November 1999, the loaded bulk carrier Alcor was upbound for Trois-Rivières, Quebec, on the St. Lawrence River, under the conduct of a pilot. At 1444 local time, while undertaking a course alteration to starboard, the vessel ran aground near the eastern end of Île d'Orléans. A refloating attempt the next evening succeeded in freeing the vessel, but only briefly, and the vessel grounded a second time near the initial grounding position. The Alcor sustained major hull damage near midships due to bending forces incurred during successive low-tide cycles.

The damaged hull was temporarily repaired and roughly half of the cargo was discharged onto smaller vessels. On December 5, the Alcor was refloated and conducted to the port of Québec. It was declared a constructive total loss.

While the Alcor was being refloated and later, while the vessel was upbound with the assistance of tugs, the Traverse du Nord section of the river was temporarily closed. The closure caused several downbound vessels to anchor upriver. The subsequent re-opening of the channel resulted in a confluence of vessels wishing to depart their anchorages. During this time, a near-collision occurred between the tanker Eternity, under way, and the container ship Canmar Pride, at anchor.

Part A - Grounding

A 1.0 Factual Information

A 1.1 Particulars of the Vessel

| Name | "ALCOR" |

|---|---|

| Official number | 7533159, International Maritime Organization (IMO) |

| Port of registry | Valletta |

| Flag | Malta |

| Type | Dry Bulk Carrier |

| Gross tonnageFootnote 1 | 16 136 |

| Deadweight Tonnage | 27 536 |

| LengthFootnote 2 | 178.2 m |

| Draught | Forward: 10.02 m Aft: 9.95 m |

| Built | 1977, Japan |

| Propulsion | Sulzer Sumitomo marine diesel engine, 11 400 brake horsepower (8385 kilowatts) driving a single fixed-pitch propeller |

| Cargo | 23 693 tonnes (t) of cement clinker, in bulk |

| Crew | 25 |

| Owner | New Wind Shipping Company Ltd., Valletta, Malta |

| Operators | Transorient Overseas S.A., Piraeus, Greece |

A 1.1.1 Description of the Vessel

The Alcor was a single-deck, dry bulk cargo vessel of all-welded steel construction. The propulsion machinery, electro-hydraulic steering gear, wheelhouse and crew accommodation were all arranged at the after end of the vessel. It was manoeuvred by a single balanced centre-line rudder.

The location of the five cargo holds, water ballast tanks and oil fuel tanks is shown in Appendix C (Outline General Arrangement). Cargo hold 3 could also be used as a water ballast (deep) tank. The hull was subdivided by seven transverse watertight bulkheads, together with an inner bottom watertight tank top, which extended fore and aft throughout the cargo holds and the engine room. The main deck, upper wing tanks, inner bottom and bottom shell plating were framed longitudinally in way of the cargo holds. The single side shell plating in way of the cargo holds and upper wing ballast tanks was framed transversely.

A 1.2 History of the Initial Grounding

A 1.2.1 The Transit

On 30 October 1999, the Alcor departed Venezuela, bound for Trois-Rivières, Quebec. The voyage north was made through heavy weather, with the vessel pitching and rolling heavily. Deck log book entries show winds of force 5 to 7 (17 to 33 knots), with two to three metre swells. On 05 November 1999, the vessel reduced speed for a time to reduce rolling/pitching and wave impact forces.

By 09 November 1999, the vessel had reached the Les Escoumins pilot boarding station in the St. Lawrence River. Draughts at this time were reported as 10.02 m forward and 9.95 m aft. At 0515Footnote 3, a river pilot boarded to take conduct of the vessel up to Québec, whereupon, after a scheduled pilot change, the vessel was to be conducted to Trois-Rivières. The voyage upriver was uneventful, with the vessel proceeding at full manoeuvring speed. In deep water, without the effects of wind or tide, this would have given a speed of approximately 11 knots. Initially, the ebb tide slowed the vessel's speed over the bottom, at times to 7 or 8 knots.Footnote 4 As the vessel progressed upriver, the flood tide gradually caught up with the vessel and her speed over the bottom increased. By 1400, the vessel had reached Sault-au-Cochon and her speed was about 13 knots.

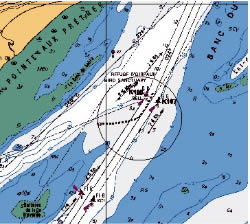

At approximately 1415, the Alcor entered the more restricted waters of the North Channel (traverse du nord) near Cap Gribane. As the vessel settled on the leading lights of 213½° True (T), the pilot confirmed his belief that the steering gyro compass repeater was showing 1° low. At the next course alteration point, Cap Brûlé, to the leading lights of 204° T, the pilot ordered a course of 201° gyro (G) to compensate for the 1° low steering repeater and the flood tide acting in a southwesterly direction. Approaching buoy K-108, the vessel was approximately 60 m to starboard of the centre of the channel, and now making 14 knots. The current was setting approximately 215° T at between 2.5 and 3.5 knots. Buoy K-108 was the location of the next course alteration, to starboard, to make the next set of leading lights, also of 213½° T. The only other river traffic in the vicinity was a downbound vessel ahead at between 1½ and 2 nautical miles (nm). (see Figure 4 for General Area Chart.)

A 1.2.2 The Grounding

The bridge watch at this time consisted of the second officer, who was the officer of the watch (OOW), the pilot, who had conduct of the vessel, and the helmsman, who was at the main steering console carrying out helm orders. The master was on the port bridge wing and the door separating the bridge wing exterior and the wheelhouse interior was ajar.

Between 1437 and 1438, with the vessel's bow about one cable below buoy K-108, the pilot requested a course alteration. According to some accounts, this was a course-to-steer order of 212° G, while according to other accounts, it was a helm order "starboard ten." The helm was placed 10° to 15° to starboard by various accounts. Soon after the helm was put over to starboard, the pilot requested more helm by using the command "more". The helmsman looked to the OOW for guidance and the OOW directed him to increase helm by 5°. He immediately put 5° more helm to starboard. The pilot, seeing the ship's head remain immobile, requested more helm by repeating "more". The helmsman applied another 5° of starboard helm. Some accounts of the events have the pilot requesting, for a third time, "more" - and an additional 5° helm was applied at this time. All concur, however, that the vessel's head was now starting to swing very slowly to starboard and the vessel's rudder was between 20° and 30° to starboard.

Unsatisfied with the vessel's rate of turn, the pilot removed the helmsman from his position at the steering console and took the wheel himself. According to one account, the pilot then turned the wheel to starboard once or twice to bring the rudder hard to starboard, 35°. However, according to other accounts, the pilot turned the wheel to starboard five to seven times, in a highly energetic fashion. Either action would have produced the same result, 35° of starboard helm. (The wheel had a slip clutch, whereby any excess turn of the wheel past the maximum did not impart further electrical signals to the steering gear.)

Having turned the wheel to starboard, the pilot immediately started turning the wheel quickly in the opposite direction and put the wheel 35° to port. The pilot noticed that the rudder angle indicator remained at 35° to starboard, and he informed the OOW of this. Some accounts have the OOW and the pilot both trying the non-follow-up (NFU) lever at this point, but others do not. Leaving the steering console, the pilot went to the very high frequency (VHF) radio to warn the downbound vessel of their situation. After this short conversation (in French), the pilot went quickly to the central control panel and put the engine-room telegraph to full astern.

While the pilot was occupied with the VHF conversation and the engine-room telegraph, the OOW approached the steering console and twice toggled the steering mode selector (SMS) switch, leaving the switch at the HAND position. He then saw the rudder angle indicator begin to move to port. At some time during these events, the OOW put the wheel to midships. He then went to the ship's public address system and announced the steering problem.

The first engineer, who was on the main deck close to the steering gear flat access door, ran immediately to this location upon hearing the announcement. As he entered the steering gear flat, he noticed the rudder was at the midship position. The time interval between the announcement by the OOW and the first engineer's arrival at the steering gear flat was about 15 seconds. He quickly verified that both steering gear pumps were on. By this time, the ship's electrician had joined the first engineer in the steering gear flat and was assisting. In order to verify the steering gear operation locally, the ship's electrician activated the switch isolating the steering gear from the bridge. The first engineer then turned the rudder a few degrees to port and to starboard locally, using the "trick wheel". The rudder responded to the trick wheel, so the bridge isolation switch was repositioned to give control back to the bridge. He then called the bridge on the sound-powered telephone and reported that the steering gear was functioning satisfactorily. The above sequence of events is summarized in Table 1.Footnote 5

| Time | Event | Result | Observations | |

|---|---|---|---|---|

| 1437:50 | 10° (or 15°) starboard helm applied | Rudder angle indicator to starboard correspondingly | No change in heading | |

| 1437:55 | 5° additional starboard helm applied | Rudder angle indicator to starboard - now 15° or 20° | No change in heading | |

| 1438:00 | 5° additional starboard helm applied | Rudder angle indicator to starboard - now 20° or 25° | OOW notices slight starboard swing | |

| 1438:05 | 5° additional starboard helm applied | Rudder angle indicator to starboard - now 25° or 30° | Pilot notices slight starboard swing | |

| 1438:10 | Pilot takes wheel and turns (many times) to starboard | Rudder angle indicator goes to hard starboard - 35° | Vessel swinging to starboard | |

| 1438:15 | Pilot turns wheel many times to port | Rudder order hard to port | Rudder angle indicator remains hard to starboard | rudder not responding to helm |

| 1438:20 | Pilot informs OOW that rudder is not responding, then leaves helm to warn downbound vessel on VHF radio | OOW approaches helm | ||

| 1438:25 | Pilot on radio | Pilot on radio (from time stamp of Vessel Traffic Services [VTS] recording) | ||

| OOW assumes helm, appraises situation | ||||

| 1438:30 | OOW toggles the SMS switch twice, leaving the switch at the HAND position | Rudder angle indicator starts to move to port | OOW and helmsman see rudder angle indicator coming to port | |

| 1438:35 | OOW puts wheel to midships position | Rudder angle indicator stops at midships position | ||

| Pilot puts engine full astern | Engine-room crew alerted to unusual situation by full astern order | |||

| 1438:40 | Engine-room crew in control room begin emergency braking on engine | Main engine r/min of engine starts to decrease | ||

| OOW makes announcement on ship's PA about steering gear problem | First engineer (in passageway adjacent to steering gear flat) hears announcement and runs to steering gear flat | Chief engineer hears announcement and looks at rudder angle indicator in control room. He sees it amidships. | ||

| 1438:55 | First engineer arrives at steering gear flat | First engineer starts steering gear verification | Upon arrival in steering gear flat, first engineer sees rudder amidships | |

By this time (1440), the ship was veering out of the channel on a heading of approximately 265° T. The master had already re-entered the wheelhouse interior and was assisting the navigation team. The chief officer had come to the wheelhouse and quickly deployed to the forecastle to standby the anchor. Shortly afterward, the astern thrust became effective and the vessel slowed considerably. The pilot was informed at or about this time that the rudder was responding to helm action. By 1444, the vessel had effectively come to a stop. Engine movements ahead were attempted in the hope of reaching deeper water, barely one cable ahead, but to no avail. The starboard anchor was then let go. The vessel was now aground, at position latitude 47°03′ 29.5″ N, longitude 070°45′ 09.1″ W, on a heading of approximately 285° T. (see Figure 1 for the vessel track as recorded by the pilot's portable differential global positioning system [DGPS].)

At 1444, the pilot reported to VTS that the vessel had left the channel but that they were not yet aground. At 1506, VTS asked the pilot if they needed assistance. The pilot responded that he thought the vessel could come free but would consult with the master. He also confirmed that the rudder was now working. At about this time, VTS inquired whether they required a speed reduction for vessels transiting the area. The pilot responded in the negative. At 1540, the pilot reported to VTS that they were still trying to extricate the vessel.

Immediately after the grounding, the master contacted the owners to consult about tugs. About one and a half hours after the grounding, at 1615, one tug was ordered via VTS. The tug Ocean Charlie left Québec at 1705 and arrived on scene at 1930, one and a quarter hours after high tide. Although on approximately the same heading of 285°, the Alcor had moved 2½ cables to the southwest, pushed by the flood tide current, and had settled in water between four and six metres above chart datum, in position latitude 47°03′ 18″ N, longitude 070°45′ 33″ W. No attempt was made to refloat the vessel at this time, as the tide had already dropped by about one metre. After consulting with officials of the Corporation des Pilotes du Bas Saint-Laurent (Pilot Corporation) by cellular telephone, the pilot decided to remain on board and assist.

By 1700, Transport Canada (TC) officials had arrived on board. Shortly after their arrival they conducted their initial steering-gear tests, which showed that the steering gear appeared to be functioning adequately and within the prescribed time limits.Footnote 6 Soundings were taken throughout the ship. Hopper tanks 2 and 3 on the port side and hopper tank 3 on the starboard side were determined to be taking on water. At 1752, the pilot of the Alcor asked VTS for a speed reduction for local traffic.

A 1.3 Injuries to Persons

No one was injured as a result of this occurrence.

A 1.4 Initial Hull Damage

Hopper tanks (water ballast) 2 (S) and 3 (P) were holed as a result of the initial grounding. The hull later sustained further extensive damage (see Part B 1.3, Hull Failure).

A 1.5 Certification

A 1.5.1 Vessel

The vessel's Certificate of Maltese Registry, Certificate of Class, International Load Line Certificate, Construction Certificate, Safety Equipment Certificate, and Radio Station Certificate were valid and appropriate to the service in which she was engaged.

Classification-related inspections and surveys of the Alcor were carried out on behalf of the owner by the Russian Maritime Register of Shipping (RS). International regulatory and national registry certification-related inspections were carried out by RS on behalf of, and under the authority of, the Government of the Republic of Malta.

The safety management systems of both vessel and management were audited by RS, and found to be in accordance with the requirements of the International Safety Management Code (ISM Code). The vessel's Safety Management Certificate was valid until April 2003; the managers' Document of Compliance was valid until March 2003.

A 1.5.2 Personnel

Certificates of competency for the master and officers were valid and complied with the provisions of the International Convention on Standards of Training, Certification, and Watchkeeping for Seafarers. The certificates were appropriate to the service in which the vessel was engaged. Qualifications of the crew were in accordance with regulatory requirements.

The master possessed a Master Mariner certificate, issued on 15 May 1992 in Ukraine.

The OOW possessed a certificate of an officer in charge of a navigational watch, issued on 14 March 1995 in Ukraine.

The pilot possessed a Master Mariner certificate, issued on 05 May 1994. He had acquired his Class C pilotage licence on 01 April 1998. Following a regulatory change that had come into effect 20 days before the accident, he was entitled to a Class C-1 licence (ships up to 30 000 deadweight tons (DWT)) with the coming into force of the amended regulation on 21 October 1999. His pilotage licence was thus amended to this higher tonnage on 02 November 1999.

A 1.6 Personnel History

The master had been at sea for 39 years, the last 10 years as master on various ships. He had been on the Alcor since 09 April 1999.

The OOW had been at sea on various ships as an OOW since May 1995. He had joined the Alcor on 09 April 1999.

The pilot had begun his sea experience as OOW in 1989. In 1992, he obtained his Master Home Trade certificate and his Master Mariner certificate in 1994. Prior to entering the Pilot Corporation, he served on ocean-going vessels as OOW for a total of 45 months' sea-time. He began his pilotage apprenticeship on 01 April 1996 and was granted his pilotage licence on 01 April 1998 having completed 226 trips on vessels of all sizes as an apprentice pilot. Since 01 April 1998 and until the Alcor assignment, he had performed approximately 175 pilotage assignments. It was his first experience on this vessel.

A 1.7 Weather, Current and Tide

A 1.7.1 Wind, Seas and Visibility

At the time of the initial grounding, on the afternoon of 09 November 1999, winds were 10 to15 knots, generally from the northeast. Visibility was good and seas were calm.

A 1.7.2 Current at the Time of Grounding

The most significant currents in the St. Lawrence estuary between Trois-Rivières and the Saguenay River are the product of tidal forces.Footnote 7 In the area of the grounding, the current changes direction from a southwesterly (upstream) flow with the flood tide to a northeasterly (downstream) flow with the ebb tide. This change in direction comes about gradually, starting about 50 minutes after high water is reached at this point. The maximum force of the tidal current varies with the tidal range, and can exceed 3 knots. At the time of the grounding, the tidal current was setting approximately 215° T at between 2.5 and 3.5 knots.

A 1.7.3 Tide

In the St. Lawrence River, tidal forces reach as far upstream as Trois-Rivières, diminishing to nearly zero on Lac Saint-Pierre.Footnote 8 The tides are a mixture of diurnal and semi-diurnal, although the semi-diurnal oscillation dominates. The result is a semi-diurnal cycle that differs in height and duration from one cycle to the next. Although the maximum tidal range is experienced at Île-aux-Coudres (7.1 m), very large ranges are experienced as far upstream as Québec (5.8 m). The reference Port of Saint-François, Île d'Orléans, some 4 nm upstream of the grounding site, has a maximum tidal range of 6.6 m.Footnote 9 The measured tidal values, in metres, for this reference port on November 09, 10, and 11 were as follows:

| Date | November 9 | November 10 | November 11 | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Time | 0115 | 0615 | 1300 | 1815 | 0145 | 0645 | 1345 | 1851 | 0230 | 0710 | 1410 | 1930 | |

| Height | high | 5.20 | 585 | 5.40 | 5.96 | 4.85 | 5.40 | ||||||

| low | 0.40 | 0.55 | 0.58 | 0.80 | 0.65 | 0.55 | |||||||

The time of the course alteration off buoy K-108, 1437, was 1 hour and 37 minutes after the measured low tide of 0.55 m. The measured tidal height at this time was 2.2 m above chart datum. The static under-keel clearance of the Alcor in the dredged channel at this time and location was, therefore, approximately 6.7 m. The measured rate of rise of the tide at this time was in the order of 1.3 m/h.

A 1.8 Bathymetry and the Navigable Channel - Traverse du Nord

From the Les Escoumins pilot station to Québec, the river channel is generally between 1 and 4 nm wide, and almost always deeper than 20 m. At Cape Gribane, however, the navigable channel narrows to 305 m, and the depth decreases. This stretch of river, between Cap Gribane and Pointe Saint-Jean, is commonly referred to as the Traverse du Nord. In the Traverse du Nord, there are two course alterations: for an upbound vessel, the first alteration is 9.5° to port at buoy K-100, the second is 9.5° to starboard at buoy K-108. The first turn has a minimum depth of 17 m and the deep water continues well beyond the buoyed channel. In the area of the second turn, near K-108, there is natural silting that requires regular dredging to maintain the guaranteed 12.5 m depth and, in this case, was actually about 14.5 m due to the dredging safety factor. Additionally, the 10 m depth contour hugs the limits of the buoyed channel at this point.

A 1.9 Navigation and Steering Equipment

A 1.9.1 Navigation Equipment

The Alcor is equipped with all electronic aids to navigation required by international conventions, including X- and S-band radars, supplemented by a global positioning system receiver. Additionally, the pilot had brought on board a portable navigation system that plotted the vessel's progress along the navigable channel. This system, a Starlink DGPS with a laptop display unit, does not show details such as coastline or soundings, but simply plots the vessel's position with respect to the buoyed, navigable channel (see Figure 2).

It also produces information such as course over-the-ground (COG), speed over-the-ground, and distance from the centre of the channel. Satellite information, DGPS correction, and other system health diagnostics can also be displayed. This system was designed specifically as a pilotage aid and was being used on a test basis during the voyage from Les Escoumins pilotage station. Although the pilot glanced from time to time at this equipment, he was using the ship's radars and visual leading lights, in the usual fashion, to conduct the Alcor up the river.

A 1.9.2 Steering Gear

The Alcor was equipped with a four ram Mitsubishi electro-hydraulic steering gear (Rapson Slide type). There are two Mitsubishi Janney pump units to pump hydraulic oil, each driven by a 15 kilowatt, 1800 r/min electric motor. One or both pumps can be put on line when operating the steering gear. With one pump operating, 65° of rudder movement takes an average of 27 seconds; with both pumps, it takes an average of 21 seconds. The gear can be operated by a local trick wheel in the steering gear flat or from the helm unit on the bridge.

The steering gear was designed to produce a torque of 50 tonne/metres (t/m) at the maximum working pressure (170 kg/cm2).

A 1.9.3 Bridge Helm Unit

The Alcor was fitted with a Hokushin steering control system, model PT-7J2. This system, fitted during construction of the vessel and approved by the classification society, includes an all-electric helm unit, incorporating hand-steering capabilities and autopilot functions. One switch selects either autopilot or hand steering and is located on the lower left-hand side of the steering unit front piece (see Figure 3, front view, switch No 1).Footnote 10

If hand steering is selected on switch No 1, a second, three-way SMS switch (No 2), labelled "Pilot Main" on this unit, permits the choice of OFF, HAND, or NFU. Switch No 2 is located on the lower right-hand side of the steering unit front piece, 55 mm behind the spokes of the steering wheel.

The detent torque required to turn the SMS switch was found to be 0.6 newton/metre (Nm).Footnote 11 No quantitative norm or regulation governing detent torque is known to exist for this type of switch in this type of application.

When the SMS switch is in the OFF position, turning the wheel or moving the NFU lever one way or the other does not impart a signal to the steering gear. With this switch in the HAND position, a signal is sent when the wheel is turned to the left or to the right - turning the wheel two full rotations is equivalent to 35° rudder angle. When the switch is in the NFU position, the spring-loaded NFU lever must be held to one side or the other for a signal to be sent to the steering gear. Turning the wheel when the switch is in the NFU position - an independent mode - does not impart a signal to the steering gear.

Steering commands from the bridge helm unit are transmitted through one of two independent wiring paths, each connected to its own solenoid valve (autopilot directional valve) at the steering gear. Signals are also amplified by one of two independent amplification arrangements. Selections are made at the bridge helm unit as to "power unit 1" or "power unit 2" (wiring path), and/or "amp 1" or "amp 2" (amplification unit). This arrangement can be interswitched in any combination and serves to provide backup in the event of any one of the systems failing. Both these switches were reported to have been in the No. 1 position at the time of the grounding.

A 1.10 Tests and Surveys of Steering Gear and Steering Control System

At approximately 1700 on 09 November 1999, TC inspectors boarded the Alcor to assess the situation and verify the seaworthiness of the vessel. Steering gear failure had been initially reported, so the inspectors surveyed the steering gear upon their arrival. Since visual inspection revealed no anomalies, inspectors carried out operational tests from the wheelhouse and the steering gear flat. The steering control system and steering gear performed without any apparent fault, although port-to-starboard operation was marginally longer than starboard-to-port operation. This may have been attributable to obstructions on the river bottom at this time, as the vessel was aground. Similar surveys and tests were carried out by TSB on 20 November 1999. No anomalies were found, and times were similar for all directions of operation.

On 15 December 1999, a complete verification of the electric components of the steering control system, including the steering station, wiring connections to the steering gear, and electrical components at the steering gear were carried out. No anomalies were found with the electrical system.

On 16 December 1999, certain hydraulic components of the steering gear (the steering pumps, relief valves and directional valves) were bench tested at a shore facility. Results showed that the steering pumps, fitted at the time of construction, had a flow capacity approximately 17% below original specifications. Solenoid valves were found to be operating normally, although one of these valves, "power unit 2", had an infiltration of hydraulic oil within its casing. The starboard relief valve was found to be leaking at low pressure and approximate crack pressure was found to be 124.14 bars (1800 pounds per square inch [psi]). The port relief valve was operating at 158.6 bars (2300 psi). The design pressure for these valves is 168.9 bars (2450 psi).

The hydraulic components that were left in place on board the Alcor, such as the rams, connecting piping, hydraulic oil reservoir and various valves, were surveyed. The main rams showed normal wear and scoring and the packing glands were seen to be leaking. The hydraulic oil in use at the time was tested and found to be more viscous than the manufacturer's recommendation.Footnote 12 The oil contained trace elements of copper, iron and lead, indicating wear in the system components. All other components were found to be normal.

Close examination of the steering gear arrangement and rudder angle indicator mechanism revealed no anomalies. When "power system 1" was selected, there was no difference between actual rudder angle and rudder command. When "power system 2" was selected, there was an approximate two to three degree difference between actual rudder angle and rudder angle command in the wheelhouse, such that when the wheel was in the midship position, the rudder was approximately two degrees to starboard.

A 1.11 Pilotage Licences - Laurentian Pilotage Authority

A 1.11.1 Current Structure

The Laurentian Pilotage Authority (LPA) is divided into four districts: District 1-1 (Port of Montréal), District 1 (Montréal to Trois-Rivières and Trois-Rivières to Québec), District 2 (Québec to Les Escoumins and Saguenay River) and District 3 (all other areas). Districts 1-1, 1, and 2 are compulsory pilotage areas; District 3 is non-compulsory.

Within each district, there are different levels of pilotage licences (Class A through Class D) based on criteria prescribed in LPA regulations. Limiting factors that define the different classes are the size of the vessel piloted and time worked at a particular level (with a minimum number of pilotage assignments). For districts 1-1 and 1, size limits of the vessels for various classes are determined by length of the vessel piloted. In District 2, it is deadweight tonnage of the vessel that defines maximum size of the vessel for a given class. Table 3 outlines these factors. Class D licences are for apprentice pilots in all districts and for any size ship in the presence of a licensed pilot.

| District | Licence | Limiting Factors | |

|---|---|---|---|

| Size of Vessel | Time to be served in class before moving to higher class | ||

| 1-1 | Class A | Ship of any size | - |

| Class B | Ship not exceeding 210 m in length | 1 year | |

| 1 | Class A | Ship of any size | - |

| Class B | In the first year, any ship not exceeding 195 m in length In the second and subsequent years, any ship not exceeding 215 m in length | 3 years | |

| Class C | In the first six months, any ship not exceeding 165 m in length In the subsequent six months, any tanker not exceeding 165 m in length, or any other ship not exceeding 175 m in length In the second and subsequent years, any tanker not exceeding 165 m in length or any other ship not exceeding 185 m in length | 2 years | |

| 2 | Class A | Ship of any size | - |

| Class B | Ship not exceeding 50 000 DWT | 6 years | |

| Class C | Ship not exceeding 30 000 DWT | 2 years | |

A 1.11.2 Evolution of LPA Regulations Regarding Pilotage Licences

In District 2, the LPA regulations with respect to the vessel size limits has often been the result of proposals made by the Pilot Corporation.Footnote 13 These proposals are often based on a popular vote within the Corporation membership. The LPA - as the legal authority entrusted with the mandate of administering, in the interest of safety, an efficient pilotage service in these areas - can accept or reject these proposals.

Evolution of the criteria defining classes of pilotage licence in District 2, both DWT and duration worked, began in 1983. In that year, the limiting factor criteria for size of vessel was changed, by regulatory amendment, in two ways.Footnote 14 First, the net registered ton (NRT) unit of measurement was changed to DWT. Although the ratio of DWT to NRT can vary widely among vessel types, a sampling of river traffic in the St. Lawrence has shown the ratio to be somewhere between 1 and 3.5, with a typical average somewhere near 2.7. Given this, the original limits as expressed in NRT for Class B and C (10 000 and 5000, respectively), would have been loosely equivalent to 25 000 DWT and 12 500 DWT, respectively. The second change brought about by the 1983 amendments was the increase of ship sizes to 50 000 DWT for Class B and to 15 000 DWT for Class C.

In 1992, time spent as an apprentice pilot in District 2 was reduced by regulatory amendment from three years to two years, although the minimum number of pilotage assignments remained approximately the same, such that the apprentices performed as many trips in two years as previously in three.Footnote 15

In 1994, the DWT limit for Class C pilots was increased from 15 000 DWT to 20 000 DWT. The accompanying Regulatory Impact Analysis Statement for the 1994 regulatory change, as published in the Canada Gazette, Part II, states, in part:

as the number of mid-sized type vessels has decreased in recent years in that district. Therefore the amendment will permit holders of licences and Class C pilotage certificates to complete their training more effectively while under this Class.Footnote 16

In 1999, the DWT limit for Class C pilots was increased once again (from 20 000 to 30 000 DWT). The following Regulatory Impact Analysis Statement for the 1999 regulatory change, as published in the Canada Gazette, Part II, states:

The use of larger ships in these waters prompted changes to subsections 15(4) and (5) of these regulations. These provisions amend the current ship limitations for holders of Class B and C licences and pilotage certificates, based on a ship's length and deadweight tonnage. This initiative provides Class B and Class C holders with the experience of piloting more ships and larger ships which were previously piloted by more senior Class holders. In addition to enhancing the knowledge and training base for these Class B and C holders, this provision provides the Authority with greater flexibility in the dispatching of its pilots, thereby improving service efficiency, particularly in peak traffic periods.Footnote 17

All of the above-mentioned regulatory changes are summarized in Table 4.

| Class | DWT (ship not to exceed) | Years Served | ||||

|---|---|---|---|---|---|---|

| Prior to 1983 | 1983 | 1994 | 1999 | Prior to 1992 | 1992 to present | |

| Class B | approx. 25 000 (10 000 NRT) | 50 000 | 50 000 | 50 000 | 6 | 6 |

| Class C | approx. 12 500 (5000 NRT) | 15 000 | 20 000 | 30 000 | 2 | 2 |

| Class D | Ship of any size (accompanied by a licensed pilot) | 3 | 2 | |||

Minimum entry-level competency for pilots in District 2 was also increased in this period. Prior to 1980, a First Mate Home Trade, or Second Mate Foreign Going certificate was required as a minimum for District 2 pilots. A 1980 regulatory amendment made Master Home Trade or First-Mate Foreign Going certificates the minimum requirement.Footnote 18

A 1.11.3 Evolution of Service Agreements Regarding Pilotage Licences

Within District 2, where the Alcor grounded, there are subclasses for Class B and Class C licences that are defined within the service agreement between the LPA and the Pilot Corporation. The service agreement respects LPA regulations for maximum DWT and duration worked and imposes lower DWT limits for the first years worked in a given class. The evolution of service agreements and the impact these agreements have had on the application of the regulation are summarized in Table 5.

| Licence Class | Period Covered by Service Agreement | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| 1983-1993 | 1993 - June 1997 |

20 July 1997 - October 1999 |

21 October 1999 - 2003 |

||||||

| Limiting Factors: Maximum DWT and Years Served | |||||||||

| DWT | Years | DWT | Years | DWT | Years | DWT | Years | DWT | Years |

| B | B-1 | 50 000 | 2 | 50 000 | 2 | 50 000 | 2 | 50 000 | 3 |

| B-2 | 35 000 | 2 | 35 000 | 2 | 40 000 | 2 | 40 000 | 3 | |

| B-3 | 25 000 | 2 | 25 000 | 2 | 30 000 | 2 | |||

| C | C-1 | 15 000 | 2 | 15 000* | 2 | 20 000 | 2 | 30 000 | 1 |

| C-2 | 20 000 | 1 | |||||||

The 2000-2003 Service Agreement reflects changes to LPA regulations that came into force on 21 October 1999. Changes include 30 000 DWT as a limit for Class C licensed pilots, up from the previous 20 000 DWT. The service agreement limits the first year worked as Class C to 20 000 DWT and then allows for the increase to 30 000 DWT in the second year worked. Also, by virtue of the service agreement, Class B-3 has been eliminated and Classes B-2 and B-1 are for three years each as opposed to the previous two years.

A 1.12 Pilotage Training

A 1.12.1 Apprenticeship Program

Pilots accepted into the program in the Laurentian Districts must undergo a two-year apprenticeship, during which they participate in pilotage of vessels in the presence of a licensed pilot. During these training trips, pilots can make written comments as to the adeptness or deficiencies observed in the apprentice's ability, but no formal guidelines exist for this process. Apprentice pilots must also undertake formal classroom instruction, in their first and second years, concerning knowledge of the district and general.htmlects of the profession, including low under-keel performance of vessels. At the end of the apprenticeship program, extensive oral and written exams are given. Vessel performance with low under-keel clearance may, or may not be, part of the series of theoretical questions asked during the exams.

LPA regulations stipulate a minimum number of pilotage assignments (113) to be made each year as an apprentice pilot, although the Pilot Corporation's training plan is more rigorous, specifying 120 trips. Harbour movages are also quantified for the major harbours of District 2 (for District 2 licences). LPA regulations do not qualify the type or size of vessel to be piloted, nor do they specify a minimum number of assignments to be made on ships with low under-keel clearance. On the other hand, the Pilot Corporation's training plan stipulates a minimum of three trips per year on vessels with draughts of 12.8 m or more. According to the Pilot Corporation, at least 25% of all pilotage assignments by apprentices are on vessels having draughts of 10 m or more. This is not a requirement, however, but a reflection of the size of vessels trading in the area.

In order to evaluate the apprentice's actual performance, the Pilot Corporation's training plan stipulates that an apprentice must make at least two trips, during the second year of training, in the company of a Pilot Corporation board member.Footnote 19 Evaluations are performed informally by observing the apprentice's pilotage skills during the trip. No formal evaluation process or tool is used during the accompanied trips and the apprentice's skill and knowledge of low under-keel clearance is not necessarily evaluated at this juncture.

A 1.12.2 Post-Apprenticeship Training

During their careers, pilots are offered additional training, including courses in bridge resource management (BRM) and ship-handling. All training deemed necessary by the Pilot Corporation is submitted to LPA for approval. Costs for training are covered off by a fixed amount allocated by LPA while the balance, if any, is assumed by the membership of the Pilot Corporation. The amount allocated for training is negotiated by the two parties and stipulated in the service contract. This amount has been unchanged since 1990. For the years 2001, 2002 and 2003, it was agreed to increase this amount to cover the costs of BRM training. BRM training has been identified as a priority and will be mandatory for all pilots by 01 January 2005.

Starting in 1972, the Pilot Corporation has been sending its pilots on a ship-handling course. Since the 1980s, this training has been a one-week course that employs working, scale model vessels that trainees manoeuvre through waterways that recreate currents, bank effect and similar phenomena. The models are used to teach practical.htmlects of ship manoeuvring. Classroom time is devoted to ship-handling theory, including subjects such as the dynamics of a vessel's pivot point.

Initially, this course was offered only to Class A pilots. Beginning in 1990, it was extended to Class B pilots. In 1993, it was enshrined in the service agreement with LPA, such that all Class B pilots would be sent on this course in the first year of their service as a Class B. As of the end of 1999, all Class A pilots in District 2 had taken the course (95% have taken it twice), as had all Class B pilots, save one. No Class C pilots had yet received this training. Because of the high cost of such training and the allocation of funds by the LPA, the Pilot Corporation could only assign a maximum of 12 participants per year to the course. If more than 12 new Class B pilots are entitled the training, participants are selected by seniority.

In other pilotage areas of Canada, candidate selection for this training is different. The Central St. Lawrence Pilot Corporation (LPA District 1) selects candidates for this training at random amongst all classes of pilots. In British Columbia, the Pacific Pilotage Authority sends all pilots on the ship-handling course during the fourth month of a six-month apprenticeship program. The Great Lakes Pilotage Authority does not, as yet, send its pilots on such training, but a recent review of training requirements has identified it as a need.

A 2.0 Analysis

A 2.1 Performance of the Steering Control and Steering Gear

A 2.1.1 Sequence of Events

According to the DGPS replay from the pilot's laptop, a decreasing trend in vessel speed had begun at 1438:10. This indicates that the turn to starboard was initiated; the drag force created by the rudder and the increased water resistance on the vessel's port side began to be felt.

A vessel making a turn with a set rudder angle will reach a maximum rate of turn for that angle and then remain stable at that rate until the rudder angle is changed. The time that the rate of turn remains stable can be considered a close approximation to the time the rudder remains at the set angle. Simulations conducted using maximum rudder angle at varying time intervals illustrate this result.Footnote 20

The rate of change of COG was analysed via data from the DGPS replay. Since wind and current were near constant, and the time interval brief, the rate of change of COG can be used here as a close analogy for rate of turn. This information shows a maximum rate of change to starboard was maintained for a very short time (15 to 20 seconds) before it decreased quickly to near zero. These data corroborate the sequence of events as reconstructed from observations of those on the bridge, in the engine control room and in the steering flat - in particular, the 15- to 20-second interval during which the helm did not respond and remained hard-to-starboard, after which the helm was placed at midships and the rudder responded.

The data collected thus indicate that the rudder remained to starboard, at varying angles, for approximately 40 to 50 seconds, of which 20 seconds were at the hard-to-starboard position (35°) and after which it went to midships. The rudder did not respond to helm orders for about 15 to 20 seconds.

A 2.1.2 Accidental Deactivation of the Ship's Wheel

The ship's records show no intermittent or chronic problems or any unusual maintenance on the steering gear or its components. Extensive testing of all electrical components (steering station, wiring and components at the steering gear), on-board inspections and extensive bench testing of the hydraulic components of the steering gear were carried out; no malfunction was apparent. Although the flow capacity of the steering gear's hydraulic pumps had diminished about 17% over 22 years of service, the steering gear could still produce a theoretical torque in the range of 40 t/m. Flow rates measured during bench testing would produce a torque of 32 t/m at an operating pressure of 103.5 bar. This would have been more than sufficient to execute rudder movements with the vessel making 12 knots through the water. The calculated torque necessary to hold or move the rudder under these conditions would have been about 12.65 t/m.

No intermittent failure was reproducible during extensive operational tests after the grounding, and there was no report or record of any intermittent failure in the past. It is unlikely that there was an intermittent failure of the steering gear at this exact time, and for this duration. Given the length of time the helm did not respond and the reported return of control after the OOW had toggled the SMS switch, loss of rudder control was probably due to the SMS switch being at a position other than HAND.

The SMS switch of the helm unit is 55 mm behind the spokes of the hand steering wheel. Simulations conducted after the accident revealed that the switch could be accidentally thrown right, to the NFU position, when the wheel was turned to the right, or left, to the OFF position, when the wheel was turned to the left.Footnote 21 With the low detent torque of 0.6 Nm, this switch was relatively easy to turn by simply leaving the fingers of the hand extended while turning the wheel (see photograph 1). The location and orientation of this switch were such that accidental activation was possible. There was no protective barrier or alarm for this switch.

Accidents in various transportation modes have been attributed to a less-than-adequate location and/or design of safety-significant controls.Footnote 22 Control actuators should be designed and located so they are not susceptible to accidental activation. Methods to reduce the likelihood of accidental activation include:

- locate and orient the control actuator so that unwanted activation is unlikely;

- provide sufficient control resistance (detent torque) to prevent unintentional movements;

- require complex motions for control activation such as an interlock or rotary motion; and

- isolate controls or provide some sort of physical barrier.Footnote 23

Many models of ship helm units incorporate safety features, such as alarms or guards on the SMS switch. These switches are also in a location and orientation that reduce accidental activation. Also, the detent torque on many models has been observed to be considerably higher than it was on the Alcor.

It is not possible to determine with certainty whether the SMS switch was moved to the NFU position (while the pilot was turning the wheel to the right) or to the OFF position (while the pilot was turning the wheel to the left). Either event would have resulted in wheel deactivation. The movement of the switch from HAND to either one of these locations would explain the brief lack of response from the rudder just prior to the grounding.

A 2.2 Ship-handling and Pilotage Experience

The vessel's head was coming to starboard even before the pilot assumed the helm. Even at a rate of turn of one third of a degree per second (a very slow turn), the 9.5° starboard alteration would not have taken more than 30 seconds, leaving two and a half minutes to position the vessel to the starboard side of the channel before meeting the downbound vessel. Instead of letting the vessel react in the time required, the pilot attempted a hard-over/hard-over counter-rudder manoeuvre.

The Alcor had a static depth of water to draught ratio (Dw/d) of 1.67 while off buoy K-108. If squat is considered, this ratio approaches 1.5. Since becoming a Class C, the pilot's experience on vessels (other than the Alcor) with reduced under-keel clearance, and thus with reduced Dw/d ratios, was very limited.

A ship can experience shallow water effect when the depth of water is less than twice the draught.Footnote 24 Shallow water effect becomes significant when the ratio of Dw/d is equal to 1.5. When this ratio is 1.2 or less, full shallow water effect is felt.Footnote 25 Full shallow water effect can double a vessel's deepwater turning diameter.Footnote 26

From Les Escoumins pilot station to Cap Gribane, the channel is wide and deep and vessels there display normal, deepwater manoeuvring characteristics. In the Traverse du Nord, however, the channel narrows to 305 m and is shallower. Additionally, at buoy K-108, the channel is dredged to keep the minimum depth at 12.5 m, and the 10 m depth contour is close to either side of the channel. In contrast, at the other course alteration in the Traverse du Nord, the channel is deeper and the deep water extends well beyond the channel limits.

The Alcor would have experienced the following effects and forces during the starboard turn at buoy K-108:

- shallow water effect - an increased resistance on the port side abaft the pivot point and the shifting aft of the pivot point due to increased resistance forward and on the port bow due to the low Dw/d ratio of 1.67 (this ratio is further reduced, to 1.5, if squat is considered);Footnote 27

- approximately 0.89 m of sinkage due to squat - being a large, full-bodied vessel, the squat tends to be more by the bow than by the stern, thereby adding to the 7 cm static forward trim, further decreasing rudder efficiency; and

- a tendency to go bodily to starboard due to a two to three knot following current, approximately 75° abaft the port beam.

The cumulative effects of the above would reduce rudder effectiveness and would account for the "sluggish" behaviour and resistance to the starboard course alteration at this point. Although the helmsman executed all helm orders correctly and without hesitation, the pilot opted to assume the helm himself at this juncture. Given the developing situation, the presence of another vessel 1.5 nm away, and the actions of the pilot at this time, this action suggests that the pilot felt pressure to get the Alcor turned, to remain on the starboard side of the channel. This is further reflected in the pilot applying full helm for a course alteration of 9.5°.

Efficient and effective ship-handling requires thinking "ahead of your ship" so the vessel reacts to helm and engine orders, and not to make helm and engine orders as a function of the ship's movement. Additionally, as a vessel's DWT increases, so does its momentum, which decreases its ease of handling, especially in confined waters with low under-keel clearance. The larger the ship, the longer she takes to respond to helm and engines; the more judgements must be based on advance knowledge and not on observation alone.Footnote 28 The pilot's actions suggest that he did not fully appreciate or anticipate the various adverse effects on the vessel's manoeuvrability due to the low Dw/d ratio, squat, and following current.

A 2.3 Pilotage: Training, Experience and Risk-based Methodology

As the size of merchant ships increased throughout the 1970s and 1980s, both LPA and the Pilot Corporation recognized the need to increase the vessel size limits at which the Class B and Class C pilots could work, to meet changes in demand for pilotage services. Changes were essential to provide LPA with flexibility to dispatch the proper class of pilot and to fully employ the group of less senior pilots as the number of smaller ships dwindled. Toward that end, LPA and the Pilot Corporation elected to use service agreement changes to supplement regulatory change. However, none of these changes (which directly affect safety) were subjected to a formal risk assessment.

A typical risk assessment methodology takes into consideration, among others, the following:

- identify the problem and associated risk factors, and develop an information base related to the risk factors;

- form a risk management team to carry out the risk assessment;

- identify and consult with all interested parties and determine their risk concerns;

- analyse risk scenarios and their frequency, consequences, and cost implications, as well as interested parties' acceptance of risk;

- identify risk control options and their effectiveness and cost implications;

- assess interested parties' acceptance of proposed actions and residual risks; and

- establish a process to monitor the chosen action.

The need for such an approach has been identified in the 1999 Canadian Transportation Agency (CTA) Pilotage Review Report, and is reflected in recommendation 1, dealing with designated compulsory pilotage areas.

As a result of changes to the licence class required for a particular vessel size, the required pilotage experience (excluding apprenticeship) of a licensed pilot on a ship of more than 25 000 DWT (such as the Alcor, at 27 536 DWT) has diminished as follows:

| Period | Prior to 1983 | 1983 - June 1997 | July 1997 - October 1999 | Since October 1999 |

|---|---|---|---|---|

| Experience | 8 | 4 | 2 | 1 |

Under the current regulation / service agreement combination, a pilot is permitted to work on ships up to 30 000 DWT one year after becoming a pilot. This level of experience (excluding apprenticeship) is one quarter of the level of experience that was required on vessels greater than 25 000 DWT before July 1997.

A 2.3.1 Pilotage Training, Experience and Performance Measurement

A 2.3.1.1 Training Requirement

The two-year pilot apprenticeship program for District 2 covers technical and local knowledge.htmlects of the profession and provides hands-on training. Apprentice pilots may select the vessels they wish to work on and are encouraged to choose as wide a variety of vessels as possible. Experience on deep draught vessels during apprenticeship is required (per the pilot corporation's training plan) to the extent of three trips per year on vessels with draughts of 12.8 m or more. However, this accounts for only 2.5% of the specified number of compulsory trips per year. Although information obtained from the pilot corporation and the pilotage authority indicates a higher level of exposure to deep draught vessels than these minimum requirements, no formal system is in place to measure and evaluate the apprentice's capacity on these vessels, and in particular the candidate's ability to handle vessels having low under-keel clearance.

With changes in the pilot licensing regime, pilots are now required to handle larger tonnage vessels earlier in their pilotage career without a requirement to gain experience on these vessels and/or through a specialized ship-handling course using manned model training.Footnote 29

A 2.3.1.2 Ship-handling Experience and Training

Ship-handling skills are acquired through a combination of formal training and practical experience. The pilot must acquire sufficient knowledge to continually evaluate the navigational situation in order to make decisions and/or take appropriate measures to safely pilot the vessel.

Formal training reinforces the knowledge of basic concepts. However, emphasis on practical experience is paramount, as it provides an opportunity for a pilot to apply those concepts in varying operational circumstances.

In the past, the longer time spent on smaller vessels allowed progressive accumulation of ship-handling experience as a pilot progressed through his/her career path. A small vessel, being more readily recovered from a ship-handling error, can add to the experience base of a pilot while the potential for adverse consequences is minimized. This slower progression to larger vessels provided pilots with an opportunity to deepen their experience base before serving on larger vessels.

Realizing that change was necessary, an initiative to adjust to larger ships navigating the St. Lawrence saw the minimum level of certification for pilotage candidates raised to Master Home Trade (or First Mate Foreign Going). While it is recognized that there is an increase in sea time for persons seeking these certificates, this does not assure that a candidate will be more skilful in ship-handling.

Specialized ship-handling courses, designed to accelerate the experience base of pilots, can be used to supplement the knowledge gained through apprenticeship. If given early enough, such a course would prepare pilots to handle larger ships at each stage of their license progression.

A 2.3.1.3 Current Practice

Recent reductions in the experience base for licensed pilots on 25 000 to 30 000 DWT vessels have not been offset by earlier training (such as the ship-handling course) or clearly defined criteria in the apprenticeship program that places a greater emphasis on vessels with low under-keel clearance. Further, under the current regime, pilots progress from one class to another, based strictly on completion of a minimum number of assignments in the required time. The ability to handle larger vessels is not qualitatively assessed at each or any stage.

Current practice within District 2 calls for all new Class B pilots to be sent for ship-handling training during their first year. With LPA regulatory/ service agreement changes, the C-1 class is now the equivalent of the old B-3 class. These pilots have less experience than their B-3 predecessors but they are not offered the same training until they become Class B pilots. Given that pilots are required to work on larger vessels earlier than before, the extension of such training to the C-1 pilots could help increase the training/experience and better prepare pilots for larger vessels.

A 2.3.1.4 Pilotage and Safety

The primary purpose of pilotage is safety. Compulsory pilotage areas are established for the benefit of the community - to protect the environment and port infrastructure from marine accidents. There is an expectation that a pilot's performance and operational procedures are of a standard that is internationally recognized and accepted. The Board, recognizing the need to maintain the highest practical safety standard for vessels operating in Canadian pilotage waters, recommended that pilotage authorities develop and implement a safety management quality assurance system.Footnote 30 The Minister of Transport accepted the recommendation and tasked the pilotage authorities to develop a pilot quality assurance system. This has also been addressed in recommendation 9 of the 1999 CTA report, which reads, in part:

that the pilotage authorities be required to develop and implement a fair and reasonable system for assessing pilots' competence and quality of service, after consultation with interested parties. This assessment process should take place regularly and not less than every five years.

Pilots working on larger ships earlier in their careers has increased the need for an effective quality assurance program. Given the reduced experience base, a competency-based training and evaluation program will permit objective evaluation of a pilot's abilities to safely navigate a vessel.

A 3.0 Findings

A 3.1 Findings as to Causes and Contributing Factors

- The combined effects of squat, shallow water effect and a following current, in conjunction with the vessel's speed and the low under-keel clearance, contributed to the sluggish steering behaviour of the Alcor off buoy K-108.

- The pilot's experience and training was such that he did not fully appreciate or anticipate the undermining effects of low under-keel clearance on the vessel's performance. By assuming the helm and employing hard-over wheel for a minor course alteration, the pilot, perceiving an emergency situation where none existed prior to his assuming the helm, set in motion the chain of events that resulted in the grounding.

- The location, orientation, and low detent torque of the steering mode selector switch, and the absence of a mechanical guard, probably allowed for the accidental deactivation of the ship's wheel, which would account for the brief lack of response from the rudder (15 to 20 seconds) just prior to the grounding. An alarm would have permitted the movement of this switch to be noticed by the navigation team at this critical time.

A 3.2 Findings Related to Risks

- The LPA allowed incremental regulatory and service agreement changes to go forward without the benefit of a formal risk assessment. This permitted handling of larger vessels by pilots who may not have been fully prepared to do so.

- The current apprenticeship and post-apprenticeship training program does not qualitatively evaluate a candidate's ability to handle larger vessels or vessels with low under-keel clearance.

A 3.3 Other Findings

- Flow capacity of the steering gear's hydraulic pumps was found to be diminished by approximately 17%, compared to original specifications, but was sufficient to execute rudder movements.

Part B - Salvage

<a id="B1"></a>B 1.0 Factual Information

B 1.1 Preparations for the First Refloating Effort

B 1.1.1 Loading and Trim

The Alcor loaded pelletized foundry clinker at Le Palito, Venezuela, on 25 October 1999. The vessel was repositioned several times during the loading operation to provide for the clear flow of cargo from the loading facility into each cargo hold. This ensured satisfactory distribution, loading rates and hull stresses. The final distribution of cargo was such that holds 1, 2, 4, and 5 were partially filled, while hold 3 remained empty.

The distribution of cargo was similar to several of the typical loading conditions included in the vessel's approved stability and strength booklet (Loading Manual). Total cargo deadweight was slightly less than that of the nearest comparable loading condition (in which hold 3 also remained empty). The lighter cargo deadweight resulted in lower sheer forces and still water bending moments (SWBM) imposed on the hull; on departure, the SWBM was approximately 40% of the approved maximum. Once loaded, the recorded draughts were 9.77 m forward and 9.86 m aft.

B 1.2 First Refloating Effort

As previously mentioned (Section A 1.2.2), one tug was ordered some 1.5 hours after the initial grounding, and it arrived on scene at 1930, 09 November 1999. After high tide, refloating the vessel was not possible, and one tug was found to be insufficient to the task.

Due to the short period before the next high tide, the unavailability of transhipment vessels, and water depth restrictions around the Alcor, no lightering operations were planned. The Alcor did not have self-unloading capabilities, so sacrificing cargo to reduce draught was not an option.

Early on the morning of 10 November 1999, loud reverberations were heard throughout the ship. Small cracks were discovered on the main deck, on the starboard side at frame 120, and on the port side between frames 95 and 100. The master, TC officials, and the pilot agreed that the Alcor should be refloated as quickly as possible, as huge strains were being imposed on the structure with each low tide. The river bottom forward was approximately two metres lower than that aft of amidships.

By the evening of 10 November 1999, some 28 hours after the grounding, a salvage effort was made with four tugs. A Lloyd's Open Form was agreed to only just before the refloating manoeuvre. By 1745, hopper tanks 2 and 3 on the port side and hopper tank 3 on the starboard side had been pressed with compressed air. Although the pilot had suggested the manoeuvre proceed to the north (moving ahead), the plan the salvors used was to pull the Alcor astern and into deeper water in a southeasterly direction. By 1755, the four tugs were in position. Three unsecured tugs on the port side pushed to keep the vessel from riding up higher onto the bank with the flood tide, while one, secured astern, pulled in a southeasterly direction.

By 1815, the Alcor was pivoting about her centre, approximately between the headings of 285° T and 055° T. At 1835, one of the three pushing tugs was sent forward, secured, and pulled in concert with the stern tug. At approximately 1900, nine minutes after the measured high tide of 5.96 m and with the flood current decreasing in strength but still in a southwesterly direction (220° T), the Alcor began to move astern under tow and her own power.

Soon after the Alcor began to move astern, the tugs stopped assisting under the salvage master's instructions, while the engine of the Alcor was kept moving astern for approximately two minutes. During this time, the vessel's heading was fairly constant at about 285° T. Soon after the vessel started astern, the salvage master inquired of the pilot, who was at one of the radars, if the vessel was in safe water. When the pilot responded in the affirmative, the salvage master put the engine of the Alcor to stop; the salvage master had not yet handed the con over to the pilot. Shortly after this, the ship stopped moving astern. The engine was again put to full astern by the salvage master and the tugs resumed their assistance, but to no avail. The Alcor had moved some 2.8 cables to the southeast and had grounded for a second time at position 47°03′08″ N, 070°45′12″ W (see Figure 5).

By 1945, the falling tide had dropped by about 0.5 m. Despite the continuous effort of the tugs, the vessel remained immobile. A decision was taken to suspend the salvage operation until the following high tide. At about 2200 that evening, the pilot requested a relief break from the pilotage dispatch centre in Québec, some 31 hours after the initial grounding.

B 1.3 Hull Failure

At approximately 0015 on 11 November 1999, a loud reverberation was heard throughout the ship. A large fracture had developed transversely across the main deck, near frame 110 on the starboard side, through the No 4 hatch coaming, and across to frame 87 on the port side. The fracture extended down both sides and stopped just short of the hopper tanks. Holds 3 and 4 were opened to the sea and the fracture on the main deck was as wide as 0.52 m in some places (see photographs 2, 3, and 4).

For safety reasons, all but a skeleton crew were evacuated from the vessel. The salvage company abandoned the Lloyd's Open Form salvage agreement and relinquished control of the vessel. Later that day, the owners of the Alcor were served a request of intention on behalf of both the Canadian Coast Guard (CCG) and TC under the auspices of the Navigable Waters, Protection Act and the Canada Shipping Act, respectively. The owners were instructed to present a plan for removal of the vessel in short order or risk loss of control of the process.

Time was of the essence, as winter ice conditions could aggravate the salvage operation and further compromise the vessel's structural integrity. First ice formation was predicted for as early as 13 December 1999.

B 1.4 Second Refloating Effort

B 1.4.1 Preparations

On 19 November 1999, a second salvage company was selected.

The refloating effort was scheduled for the evening high tide of 07 December 1999. As this date approached, unfavourable winds were predicted for both December 06 and 07. The refloating was advanced to the afternoon high tide of 05 December 1999. By then, preparatory work for refloating had been completed, which included an underwater survey of the hull, ballasting down, strengthening in way of the fracture, removal of unnecessary fuels, lightering of cargo (approximately 11 200 t had been taken off), and a detailed hydrographic survey of the grounding area. Three special buoys had been placed nearby to indicate the deep water limits in the vicinity of the vessel.

Closing the Traverse du Nord during the refloating and transit of the Alcor through this section of the river had been discussed informally by TC, CCG, and salvors. However, no explicit plan or directive was in place to execute this action.

On the morning of 05 December 1999, the salvage master briefed officials from CCG and TC, as well as the refloating team, including the tug masters, and the owners' representatives, on the planned manoeuvre. The plan was to move the vessel forward once afloat, and then turn her stern to starboard in order to back her out of the confined area bordered by shoals on either side. Once in safe water, the con was to be passed to a river pilot for passage to Québec. The four river pilots scheduled for the operation, two for the Alcor and two for the lead tug, were not present at this time, but were briefed upon their arrival on board a few hours later. Although no specific location was indicated at which the hand-over from salvage master to pilot was to take place, the pilots were informed that they would be handed the con once the vessel was safely in the channel.

B 1.4.2 Refloating Manoeuvre

The Alcor had come afloat by 1515 and two unsecured tugs were used on the port side to keep the vessel on station. One tug had been secured forward and another secured aft. At this time, the refloating team, TC, and CCG conducted a survey to assess the structural integrity of the vessel before moving it into deeper water. The gyro compass was now unreliable and could not be used. The magnetic compass was also unreliable, due to the considerable amount of reinforcing steel brought on board to strengthen the broken vessel. Although the vessel's radars were operational, they had to be used in the ship's head-up configuration due to the unreliable gyro input.

In the wheelhouse at this time, apart from TC and CCG officials who were observing the operation, the bridge team consisted of the salvage master, a salvage captain (acting as master), and the two river pilots. There was no dedicated helmsman or OOW.

At approximately 1540, under her own power and with the help of the tugs fore and aft, the Alcor was first moved forward (see Figure 6, position 1) and then pivoted, the stern moving to starboard, until the vessel was on an approximate heading of 215°T, parallel with the shoals on either side (see Figure 6, position 2). Once in this orientation, sternway was put on using the stern tug and the engine of the Alcor. The operation was executed as initially planned.

At approximately 1550, with the bow of the Alcor just past the special buoy to port (see Figure 7, position 3), the salvage master asked if one of the pilots was ready to assume conduct of the vessel. The first pilot replied in the affirmative and took the con, asking the stern tug to pull in the direction of the K-108. The second pilot was using one of the radars and the salvage captain the other. Although visibility had been good before the refloating, it had now diminished to approximately 0.5 nm, and even less at times.

The Alcorwas still going astern when the salvage captain, who was also plotting positions on the chart, declared that the vessel was coming dangerously close to the shoal named "Le Banc de Sable", 1.2 nm south-southwest of Cap Tourmente. Although the second pilot, who was verifying the vessel's position on the radar, was sure the vessel still had plenty of sea room, the first pilot, who had the con, ordered the stern tug to stop pulling and ordered ahead engine on the Alcor. The salvage master put the engine-room telegraph to half ahead (see Figure 7, position 4).

B 1.4.3 Change in Plans

During the astern manoeuvre, the Alcor had inadvertently been allowed to turn to port, from an initial heading of 215° T to somewhere between 140° T and 150° T. There are differing views as to why this happened, but it is generally accepted that there was an unwanted pulling in the forward tug's towline as the astern manoeuvre was carried out. Ideally, this line would have remained slack throughout the astern manoeuvre. Later, with ahead thrust from the Alcor and the forward tug now pulling, the Alcor stopped moving astern and began to move forward. Shortly thereafter, at approximately 1615, out of the mist ahead and to starboard, the buoy SB3 became visible from the wheelhouse of the Alcor (see Figure 7, position 5). The second pilot, who had been assisting, became more assertive in the absence of any orders from the first pilot. He ordered the lead tug to pull the Alcor in the direction of K-108, in order to distance the vessel from the shoal water to starboard. This action further moved the bow of the Alcor to port, to a heading of between 110° T and 100° T as the vessel entered the channel (see Figure 7, position 6).

As she came into the channel, the Alcor was now headed more downriver than upriver. The second pilot, who had by now assumed de facto con of the vessel, decided to continue downriver and turn at Sault-au-Cochon, where more sea room was available to manoeuvre. By 1617, the vessel was straightened out in the channel and headed downriver.

B 1.5 Damage Subsequent to the First Refloating Effort

During the early morning hours of 10 November 1999, near low tide, small cracks on the main deck were observed and recorded by the crew: near frame 120 on the starboard side and between frames 95 and 100 on the port side. The river bottom at this initial grounding position was such that the aft 40% of the vessel was in approximately four metres of water while the fore part of the vessel was on a gradual slope to deeper water with the bow in about six metres of water.Footnote 31

Orientation of the vessel in the second and final grounding position, shortly after 1900 on 10 November 1999, and its "footprint" on the riverbed were such that the bottom shell plating aft of midships was in approximately 2.5 m of water. This part of the vessel thus maintained effective bearing contact throughout the tidal cycles. The forward half of the vessel was on a gradual slope, with the bow in about five metres of water. The buoyant support of the forward half of the grounded vessel fluctuated as the water level rose and fell with the tides. The maximum tidal range prior to the main structural failure of the Alcor was 5.31 m, which was slightly more than half of her original forward draught when afloat.

Once settled in the final grounding position on 10 November 1999, conditions that created very high bending moments and tensile stresses in the upper members of the hull girder included:

- a large reduction of buoyant support during the low tides,

- a loss of intact hull buoyancy due to flooding of breached hopper ballast tanks 2 and 3 (P), and 3 (S), and

- a deadweight of cargo in holds 1 and 2 in the unsupported forward end of the vessel.

The SWBM near the mid-length of the hull was much greater than the approved maximum SWBM related to the vessel when free floating, and eventually exceeded that which the main deck structure of the grounded vessel could withstand.

Tensile stress concentrations at minor discontinuities in the upper members of the hull girder initiated brittle fractures in the main deck plating that subsequently propagated across the deck, into the deck longitudinals, then through the sheer strake and gunwale, finally propagating down the side shell plating.

Principal fractures in the port and starboard side shell plating breached the watertight integrity of cargo holds 3 and 4 and upper wing water ballast tanks 2 (S) and 3 (P). The width of the fractures across the main deck plating near midships widened to approximately 0.52 m.

The longitudinal integrity of the hull was only maintained by the bottom shell plating, the inner bottom tank top plating, and the internal double bottom structure. These lower members of the hull girder were subjected to compressive stress loading and remained intact, collectively acting in the manner of a large hinge.

B 1.6 Damage to the Environment

The grounding was within 0.5 nm of a bird sanctuary on the banks of the St. Lawrence River. Also, the area is the natural habitat for several species of duck. Approximately 25 t of clinker spilled out of holds 3 and 4 into the St. Lawrence River.

Clinker is not considered a marine pollutantFootnote 32 and the spill was found to pose no risk to the bird or fish habitat. No heavy fuel, diesel or other marine pollutant was released into the environment subsequent to either the grounding or the rupture of the ship's structure.

B 1.7 Weather, Current and Tide

On the evening of 10 November 1999, at the time of the first refloating effort, winds were 15 to 20 knots from the northeast. Visibility was at times reduced by snow, but on the whole remained good. The tidal current at 1900 was in a southwesterly direction, setting approximately 220° T at between 0.5 and 1 knot.

On 05 December 1999, during the successful refloating, visibility was reduced at times to less than a one nautical mile due to mist, particularly during the actual refloating manoeuvres between 1530 and 1630, where at times it was reduced to less than 0.2 nm. Once the Alcor was in the channel and underway, visibility was reported as good. At 1600, as the vessel was moved into the channel, the tidal current was setting approximately 220° T at between 0.5 and 1 knot. Winds were calm at this time.

B 1.8 Governmental Infrastructure

The waters in question are within VTS jurisdiction. The VTS mandate, other than communications, is generally limited to traffic advisories and information. Under special circumstances, VTS can direct traffic. (See section C 1.5 of this report for details on traffic direction.)

Another division of CCG was quickly involved in the Alcor incident: the Environmental Response Division of the regional Coast Guard / Marine Programs Directorate. As per their mandate, they monitored the situation for environmental considerations.

Transport Canada Marine Safety (TCMS) was active during the period that the Alcor was aground. TCMS surveyors were aboard the vessel within hours of the grounding. After the hull fracture, they remained on board on a continuous basis to monitor the vessel's condition. Once the second refloating effort was underway, they re-evaluated the structural integrity of the vessel before allowing the transit to Québec.

The Navigable Waters Protection Act provides the Minister with the necessary powers to remove a stranded vessel if the difficulty or danger continues for more than 24 hours.Footnote 33

B 1.9 Pilot Relief (District 2)

For District 2, paragraph 35 of the LPA regulations stipulates that two pilots are assigned to a vessel when any one of the following conditions are met:

- the ship is likely to be under way for more than 11 consecutive hours in that district;

- on a ship in excess of 74 999 DWT;

- on a tanker of 40 000 DWT or more;

- on a passenger ship of more than 100 m in length, or