Landing gear collapse

Northwestern Air Lease Ltd.

British Aerospace P.L.C. Jetstream Model 3112, C-FCPE

Fort Smith Airport (CYSM), Northwest Territories

The Transportation Safety Board of Canada (TSB) investigated this occurrence for the purpose of advancing transportation safety. It is not the function of the Board to assign fault or determine civil or criminal liability. This report is not created for use in the context of legal, disciplinary or other proceedings. See Ownership and use of content. Masculine pronouns and position titles may be used to signify all genders to comply with the Canadian Transportation Accident Investigation and Safety Board Act (S.C. 1989, c. 3).

Summary

At 1025 Mountain Daylight Time on 14 April 2023, the Northwestern Air Lease Ltd. British Aerospace P.L.C. Jetstream Model 3112 aircraft (registration C-FCPE, serial number 825) departed Fort Smith Airport (CYSM), Northwest Territories, on a training flight (flight PLR732T) with the captain and the first officer on board. At 1227, the aircraft returned to the airport. Shortly after landing, the left main landing gear unit collapsed, and the aircraft veered off the runway. There were no injuries. The aircraft’s left main landing gear unit, engine, propeller, and wing tip, as well as its belly cargo pod, were significantly damaged.

1.0 Factual information

1.1 History of the flight

At 1025All times are Mountain Daylight Time (Coordinated Universal Time minus 6 hours). on 14 April 2023, the Northwestern Air Lease Ltd. (NWAL) British Aerospace P.L.C. (British Aerospace) Jetstream Model 3112 aircraft departed Fort Smith Airport (CYSM), Northwest Territories, on a visual flight rules training flight (Canadian Aviation Regulations Subpart 704), flight PLR732T, with the captain and the first officer (FO) on board.

The training flight consisted of the following exercises:

- Takeoff and landing data calculations

- A normal takeoff with a crosswind

- Steep turns

- 4 different stall configurations

- A V2 cutAccording to NWAL, a V2 cut entails a missed approach, followed by a simulated engine failure just as the missed approach is initiated. at altitude

- Flight in volcanic ash

- Flight in turbulent air

- A very high frequency omnidirectional range (VOR) hold with a simulated right-engine fire

The FO, who was being trained, was the pilot flying.

The training flight travelled approximately 61 nautical miles south-southwest to Peace Point, Alberta, on the Peace River, before returning to CYSM at 1227. The captain and FO then conducted a final training exercise, the VOR RWY 12 circling approach for Runway 30 with a simulated single engine followed by an emergency evacuation procedure after landing. The aircraft was configured with the landing gear down and the flaps set to 20° on final approach to Runway 30.

During the initial landing flare, the aircraft ballooned, and the captain corrected the flight path. The first officer subsequently landed the aircraft at 1230. During the rollout, the left main landing gear (MLG) unit collapsed, and the captain took control of the aircraft. The aircraft then skidded off the left side of the runway approximately 1880 feet beyond the threshold, contacting and severing a runway edge light. The aircraft came to rest in the grass approximately 2800 feet from the touchdown point. The captain then shut down the aircraft and discharged the engine fire bottles before he and the first officer evacuated through the main cabin door without any further incident.

1.2 Injuries to persons

There were no injuries.

1.3 Damage to aircraft

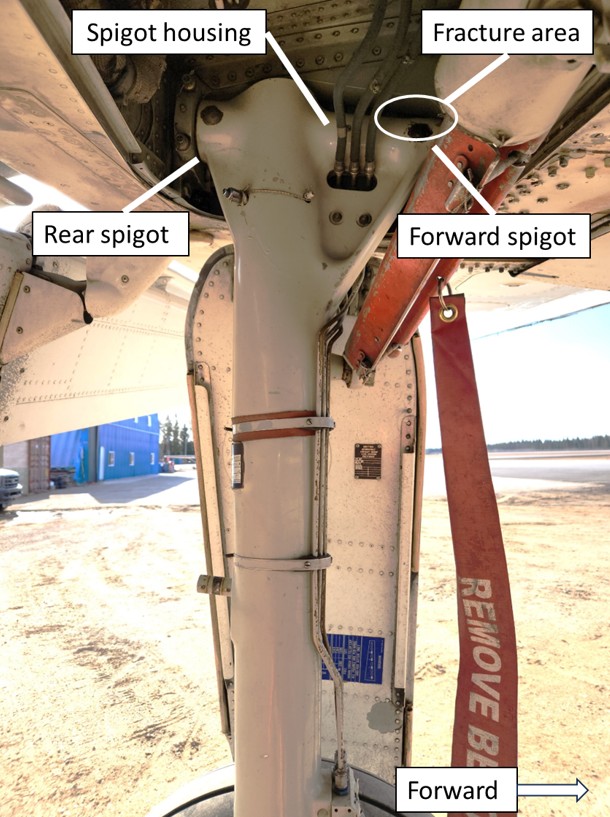

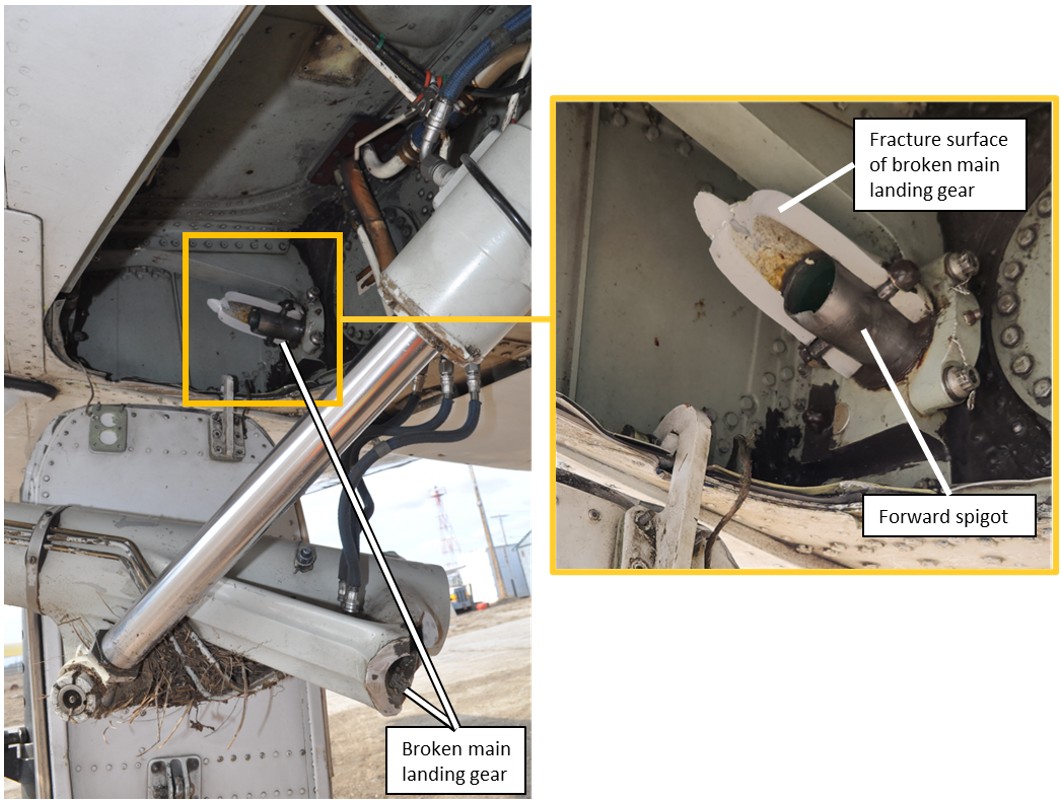

The aircraft remained upright during the landing but was substantially damaged (Figure 1) when the left MLG unit collapsed as a result of a failed spigot housing.In 3 of the main service bulletins (SBs) related to the maintenance of the MLG (SB 32-A-JA 851226, SB 32-19, and SB 32-JM7862), the term “spigot housing” is used. This term is used throughout this report. However, this structural component of the MLG is also referred to as the “pintle” or “yoke pintle” in other sources, including SB 32-A-JA 140940, SB 32-56, SB 32-JA960142, and European Union Aviation Safety Agency (EASA) Airworthiness Directive (AD) 2016-0224. For the full titles of these sources, refer to section 1.18.2 Current airworthiness directives and service bulletins related to the main landing gear in Jetstream 3100 series aircraft in this report. The left MLG unit, wing tip, propeller, and engine were significantly damaged, as was the belly cargo pod.

1.4 Other damage

A runway edge light was damaged when the aircraft skidded off the runway.

1.5 Personnel information

Captain | FO/trainee | |

|---|---|---|

Pilot licence | Airline transport pilot licence - aeroplane | Commercial pilot licence - aeroplane |

Medical expiry date | 01 October 2023 | 01 May 2023 |

Total flying hours | 11 018 | 269 |

Flight hours on type | 8067 | 5.5 |

Flight hours in the 24 hours before the occurrence | 2.3 | 2.3 |

Flight hours in the 7 days before the occurrence | 7.5 | 3.6 |

Flight hours in the 30 days before the occurrence | 10.6 | 5.5 |

Flight hours in the 90 days before the occurrence | 46 | 38 |

Flight hours on type in the 90 days before the occurrence | 46 | 5.5 |

Hours on duty before the occurrence | 4 | 4 |

Hours off duty before the work period | 15 | 72 |

On the occurrence flight, the captain, who was NWAL’s chief pilot, sat in the left seat and was the pilot monitoring. The FO, who was being trained, sat in the right seat and was the pilot flying.

The captain held a valid airline transport pilot licence - aeroplane with a Group 1 instrument rating. He held a type rating for the British Aerospace Jetstream 3100 (BA31) and 3200 (BA32) series aircraft. The captain had been employed with NWAL since April 2003; he started as an FO and became a captain in 2005. In 2006, he became a training captain, and in 2008, he became the chief pilot.

The FO held a valid commercial pilot licence - aeroplane and a Group 1 instrument rating. At the time of the occurrence, the FO had recently been hired by NWAL and was being trained to be an FO on the Jetstream 3100 and 3200 series aircraft.

The captain and FO both held the appropriate licence and ratings for the flight in accordance with existing regulations.

1.6 Aircraft information

Manufacturer | British Aerospace P.L.C.* |

|---|---|

Type, model, and registration | Jetstream Model 3112, C-FCPE |

Year of manufacture | 1988 |

Serial number | 825 |

Certificate of airworthiness date | 03 February 1989 |

Total airframe time | 28 346.3 hours |

Total airframe cycles | 28 956 |

Engine type (number of engines) | Garrett TPE331-10UGR-516H (2) |

Propeller type (number of propellers) | MT-Propeller GmbH MTV-27-1 (2) |

Maximum allowable take-off weight | 15 322 lb (6950 kg) |

Recommended fuel type(s) | Jet A. Jet A-1, JP-8 |

Fuel type used | Jet A |

* BAE Systems (Operations) Limited (BAE Systems) currently holds the type certificate for the aircraft type.

The British Aerospace Jetstream 3100 series aircraft is a turboprop aircraft with a seating capacity of 19 passengers. At the time of the occurrence, only 2 aircraft of this type, including the occurrence aircraft, were being operated in Canada.

The occurrence aircraft had been operated by NWAL since 1995 and had been maintained in accordance with a maintenance schedule approved by Transport Canada (TC). There were no recorded defects outstanding at the time of the occurrence.

The aircraft was in maintenance from August 2022 until February 2023. On 22 February 2023, the maintenance was completed and certified at a total airframe time of 28 331.5 hours and 28 942 landing cycles. Several flights, including the occurrence flight, were conducted during the period from 22 February 2023 to 14 April 2023, totalling 14.8 hours and 14 landing cycles. There were 12 additional maintenance entries in the technical records for ongoing maintenance over the same period.

The occurrence training flight had a take-off weight of 13 119 pounds and a landing weight of 11 768 pounds. The aircraft’s weight was within the maximum landing weight and within the centre of gravity envelope.

1.6.1 Main landing gear

The Jetstream 3100 series MLG is hydraulically actuated to extend and retract. Shock absorption is provided by an oleo that is incorporated into each of the landing gear units. Each MLG cylinder is made of DTD 5094 aluminum unless the modifications described in optional Service Bulletin (SB) 32-JA-880340Jetstream, Service Bulletin (SB) No. 32-JA-880340: Landing Gear – To Introduce Main Landing Gear Cylinders Manufactured from L161 Material (06 January 1989). have been carried out,The accomplishment instructions for complying with SB 32-JA-880340 are contained in British Aerospace, Dynamics Division, Service Bulletin No. 32-36: Landing Gear – Main Gear – Fit Cylinder Manufactured from New Material (20 July 1988) and APPH Precision Hydraulics, Service Bulletin No. 32-67: Landing Gear – Main Gear – New Casing Introduced (January 1999). which replace the cylinders with new ones manufactured from composition controlled L161 material. The occurrence aircraft did not have the modifications described in this optional SB carried out.

Each MLG unit is attached to the wing by half cap bearing housings mounted to the spigots through the spigot housing. During the landing of the occurrence flight, the spigot housing of the left MLG unit failed, resulting in the collapse of this MLG unit (figures 2, 3, and 4).

At the time of the occurrence, the MLG had 1274 cycles since its overhaul in December 2016. The left MLG unit had been installed on the occurrence aircraft on 22 September 2020, and at that time, it had 644 cycles since overhaul. Since the installation of the left MLG unit in 2020, the MLG had been inspected 3 times by eddy currentFor a description of eddy current inspections, refer to 1.12.7 Eddy current inspection in this report. (the same inspection carried out at overhaul) and 10 times visually. As required by European Union Aviation Safety Agency (EASA) Airworthiness Directive (AD) 2016-0224,European Union Aviation Safety Agency (EASA), Airworthiness Directive (AD) 2016-0224: Landing Gear – Main Landing Gear – Inspection / Replacement (issued 09 November 2016). the last non-destructive testing (NDT) inspection using eddy current was completed on 13 December 2022, and a maintenance release was signed in the aircraft journey log on 22 February 2023 (at 28 942 airframe cycles). A visual inspection was also completed on 22 February 2023.

During the December 2022 eddy current inspection, a discontinuity (corrosion pit) was found at the 6 o’clock position on the forward face of the spigot housing. This discontinuity was repaired at that time.

1.6.1.1 Main landing gear maintenance requirements

EASA AD 2016-0224 mandates that the MLG be inspected in accordance with BAE Systems SB 32-A-JA 851226.

SB 32-A-JA 851226 requires that inspections be carried out in 2 parts. Part A, which consists of NDT using eddy current, must be completed within either 300 landings (landing cycles) or 3 calendar months of the initial receipt of this SB and repeated every 1200 landings or within 1 calendar year, whichever is sooner. An eddy current inspection is also required within 300 landings or 3 months of an “abnormal or heavy landing.”BAE Systems (Operations) Limited, Service Bulletin (SB) 32-A-JA 851226: Landing Gear – To Introduce NDT and Visual Inspections of Main Landing Gear Spigot Housing for Cracks, Revision 8 (12 November 2020), 1. Planning Information, p. 4. Part B, which involves an intermediate visual inspection, is required at intervals of 300 landings or 3 calendar months, whichever is sooner.Ibid.

The SB stipulates that part C, which details an eddy current NDT inspection of the microswitch hole, is required if the MLG has a microswitch hole in each cylinder web.Ibid. This inspection is not applicable to the MLG involved in the occurrence, which did not have microswitch holes.

SB 32-A-JA 851226 refers to several other SBs that provide instruction to accomplish the inspections and are referenced throughout this report.For a list of current SBs, refer to section 1.18.2 Current airworthiness directives and service bulletins related to the main landing gear in Jetstream 3100 series aircraft in this report.

AD 2016-0224 also requires compliance with SB 32-JM7862, which was issued by the manufacturer to protect each MLG unit’s forward spigot from environmental degradation that could lead to cracking. This SB calls for the restoration of protective treatment (Alocrom 1200 or Alodine) to the forward face of the spigot housing (if necessary), the installation of a protective tabbed washer to the forward face using Loctite sealant, and the application of a corrosion prevention compound (Tectyl 502-C) to the remaining exposed surface of the forward face.BAE Systems (Operations) Limited, Service Bulletin (SB) 32-JM7862: Landing Gear – Introduction of Special Washer to Protect the Main Landing Gear Cylinder at the Forward Spigot, Revision 4 (11 January 2016), 2. Accomplishment Instructions, B. Accomplishment, pp. 7–8. After the washer is installed, a witness mark must be painted on the tabbed portion to identify inadvertent washer rotation during service.Ibid., p. 7.

1.6.2 Extension of time between overhaul in approved maintenance schedule

According to the TC-approved maintenance schedule, the manufacturer requires that the MLG be overhauled at 10 000 landing cycles or 6 years, whichever occurs first. However, NWAL sought approval to extend the calendar time between MLG overhauls to 9 years on the grounds that the MLG would accumulate only 4000 to 6000 cycles, or 40 to 60% of the limit, in the 6-year period. In addition, NWAL argued that the MLG parts had a less-than-average amount of wear and tear and that the annual overhaul costs were well below the standard overhaul allowance, an indicator that the MLG was in a good state of repair. The extension process did not include any discussions with the manufacturer. TC agreed with NWAL and approved the extension in 2012. The manufacturer’s requirements would have had the MLG overhauled in December 2022, but with the extension granted by TC, an overhaul was not required until December 2025. The left MLG unit failed during the occurrence flight in April 2023.

In TC’s Civil Aviation Maintenance Schedule Approval Policy and Procedures Manual (TP 13094), which was designed to provide guidance to industry personnel regarding the development and approval of aircraft maintenance schedules, section 13.1 states:

Changes for economic reasons will require the demonstration of an acceptable level of reliability, in the form of workshop reports, inspection findings, etc. Increases in the times between overhaul (TBO) of major items such as engines and propellers should normally be based upon a trial/sampling program.Transport Canada, TP 13094, Civil Aviation Maintenance Schedule Approval Policy and Procedures Manual, Revision 03 (June 2006), Chapter 3: Approval, section 13.1.

NWAL had requested this extension for economic reasons. TC did not have any information available validating any data or internal research, other than the authorizing letter to NWAL.

At the time of the occurrence, even though TC had extended the calendar requirement for the MLG’s overhaul beyond the manufacturer’s 6-year requirement, the inspections required by AD 2016-0224 for the detection of cracks had still occurred annually since the last overhaul inspection, during which time no cracks had been found.

1.7 Meteorological information

The aerodrome routine meteorological report (METAR) for CYSM issued at 1200 reported the following:

- Winds variable at 6 knots

- Visibility of 15 statute miles

- Few clouds at 12 000 feet above ground level (AGL) and 18 000 feet AGL, with a broken ceiling at 24 000 feet AGL and another broken cloud layer at 27 000 feet AGL

- Temperature 4 °C and dew point −5 °C

- Altimeter setting 30.02 inches of mercury

Weather was not considered to be a factor in this occurrence.

1.8 Aids to navigation

Not applicable.

1.9 Communications

There were no known communication difficulties.

1.10 Aerodrome information

CYSM is a certified aerodrome located on the south side of the Slave River, west of the town of Fort Smith, Northwest Territories. The airport has 2 intersecting runways. Runway 03/21 is approximately 1800 feet long and 100 feet wide, and its surface is a combination of gravel and asphalt. Runway 12/30 is considered the main runway. Measuring 6001 feet long and 100 feet wide, it is 100% asphalt.

1.11 Flight recorders

The aircraft was equipped with a cockpit voice recorder, which had a recording capacity of 2 hours. Its recorded data were successfully downloaded and contained audio of the occurrence flight.

The aircraft was not equipped with a flight data recorder, nor was one required by TC regulations.

1.12 Wreckage and impact information

1.12.1 General

During the landing of the occurrence flight, the left MLG unit fractured at the forward section of the spigot housing and was not able to hold the weight of the aircraft. The left wing and propeller as well as the belly cargo pod contacted the runway during the rollout.

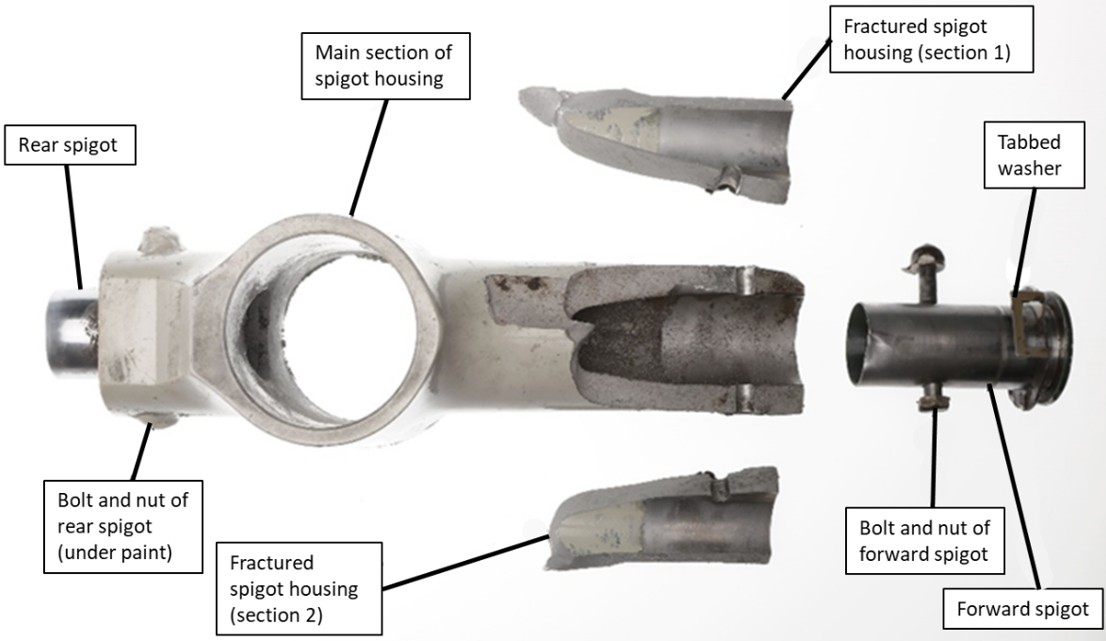

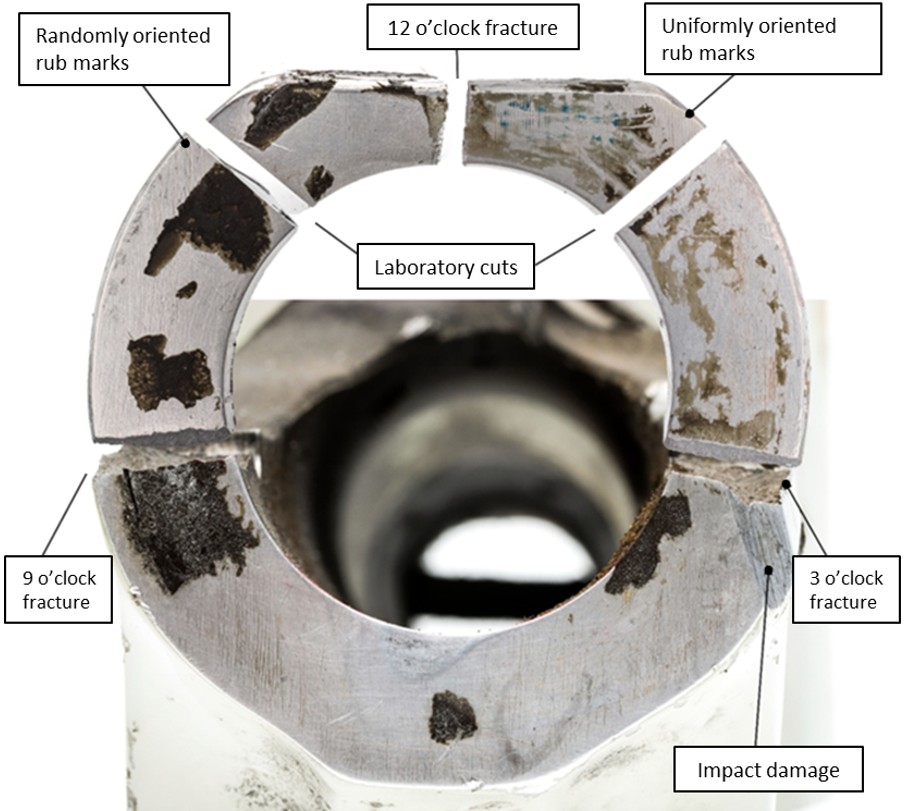

The forward end of the spigot housing fractured into 3 pieces (Figure 5), causing part of it to separate from the forward spigot and fall away. The spigot was retained by the half cap bearing housing that held the gear to the aircraft.

The TSB laboratory carried out an in-depth examination of the failed parts of the left MLG unit.

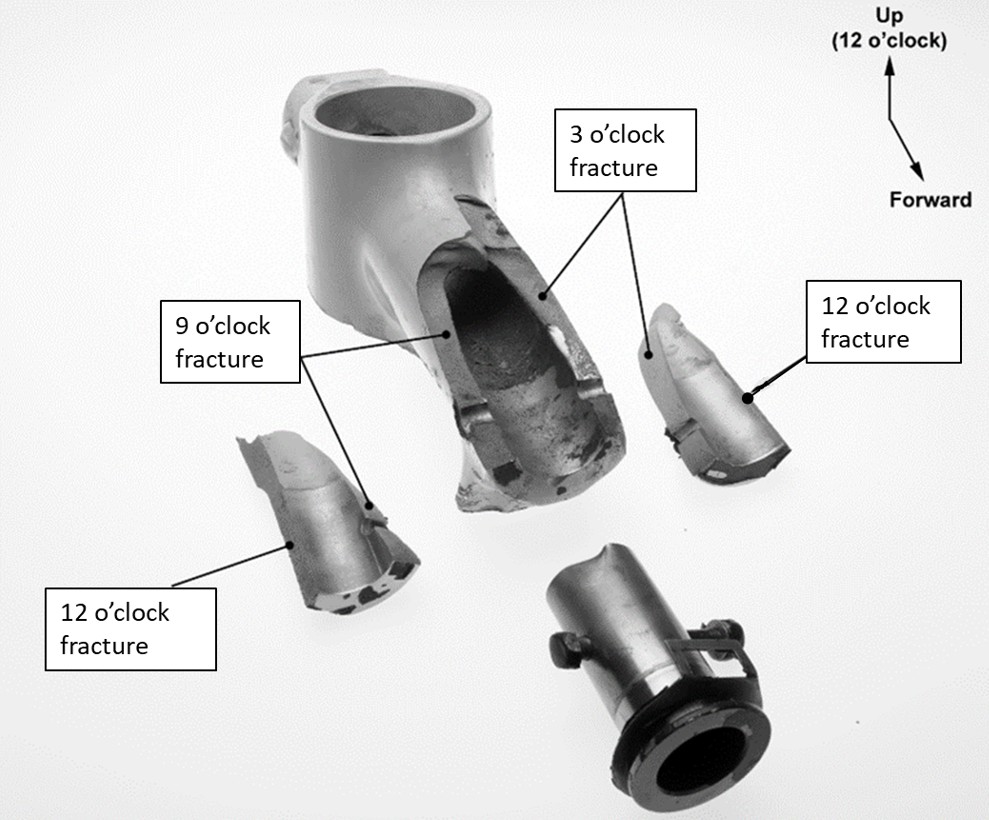

1.12.2 Visual examination of fractures

When the forward end of the MLG unit’s spigot housing was visually examined and found to have broken into 3 pieces, fractures were observed at the 3 o’clock, 9 o’clock, and 12 o’clock positions (Figure 6).

The 3 o’clock and 9 o’clock fractures each intersected a bolt hole, indicating that they each consisted of 2 independent fractures, 1 forward and 1 aft of the bolt hole (Figure 6). Sealant was observed on the edge of 1 of the mating fracture surfaces, adjacent to the forward face of the spigot housing. The forward face of the spigot housing (Figure 7) was also examined for evidence of corrosion protection. Some brownish and black sealant residue (likely Loctite 5188) remained on the forward face; however, there was no visual indication of a chemical conversion coating,Chemical conversion coating is a surface treatment process for metals that is designed to provide corrosion protection. Through a chemical reaction, a metal’s surface is modified so that a thin protective layer forms. such as Alocrom 1200 (golden in colour) or Tectyl 502-C (an amber-coloured wax compound). There was also no evidence of primer, paint, or a chemical conversion coating on the repaired area.

The tabbed washer (Figure 5), which had been installed to the forward face of the spigot housing, was also examined for evidence of rotation. No evidence of rotation was observed; however, it was noted that there was no painted witness mark on the tab, as is required by SB 32-JM7862.

The forward face of the spigot housing and the inside of the spigot housing’s bore were also examined for corrosion and cracking. One crack was observed on the forward face at the 12 o’clock position, adjacent to the bore and the fracture. No significant amount of corrosion was observed.

1.12.3 Microscopic examination of fractures

The forward face, inner bore surface, and painted surface were also examined using a scanning electron microscope. Surface cracks were observed along the forward face surface, close to the main fracture at 12 o’clock, and most of these cracks were minute (less than 0.505 mm, or 0.02 inches, long), except the larger crack that had been observed macroscopically. This larger crack was 1.6 mm (0.06 inches) in length, and approximately half of the crack was filled with what appeared to be sealant. Qualitative energy dispersive spectrometry (EDS) was carried out both on the sealant adhered to the forward face of the spigot housing and on this material protruding from the larger crack. Both spectra were very similar, and it is likely that the material within the crack originated from the sealant used during the installation of the washer. None of the other surface cracks appeared to be filled with sealant. Other than the cracking, very little corrosion pitting was observed.

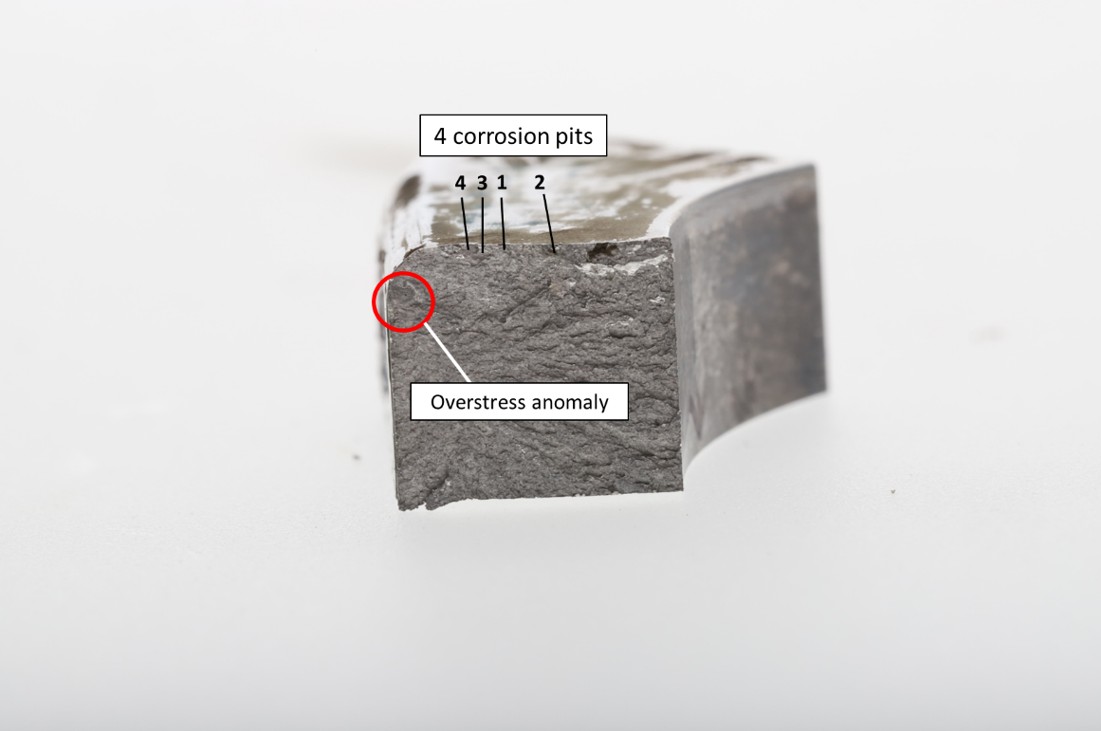

The features observed on the 12 o’clock fracture surface mainly consisted of rock candyA rock candy fracture in metal is a type of fracture that is intergranular, meaning that the metal breaks apart by cracking along grain boundaries rather than through the grains themselves. The surface of such a fracture resembles that of rock candy. fracture features (indicative of intergranular fracture) and ductile dimples (indicative of ductile overstress). These features initiated from 4 small corrosion pits and 1 overstress anomaly, the latter of which appeared as a dark circular feature (Figure 8). The 3 and 9 o’clock fracture surfaces also contained rock candy fracture features and ductile dimples. However, on those 2 fracture surfaces, there was no fatigue and very little corrosion pitting, and the origin of the intergranular cracking could not be determined from the features that were observed.

1.12.4 Further examination of the forward face of the spigot housing

EDS was also performed on the forward face of the spigot housing in multiple locations to determine if there was evidence of Alocrom 1200 (or Alodine) or SurTec 650 (both are chromium-rich chemical conversion coatings). The EDS analysis found a minor amount of chromium in all analyzed locations, except in the repaired area at the 6 o’clock position (no coating was present in this repaired area). The analysis also found that the fracture at the 12 o’clock position had likely originated at an overstress anomaly and various minute corrosion pits, none of which were larger than 6 mm (approximately 0.2 inches), the critical crack length.The critical crack length is the length at which the crack growth becomes unstable.,United Kingdom Air Accidents Investigations Branch (AAIB), AAIB Bulletin 10/2012, G-CCPW, EW/C2012/03/03 (08 March 2012), p. 30. The cause of the overstress anomaly is unknown, and the formation of corrosion pits indicated that the base material had been exposed to the environment at some point in time.

Although the EDS analysis confirmed that a chromium-based chemical conversion coating was present on the forward face of the spigot housing, other than at the repaired area at the 6 o’clock position, this coating could not be seen, as noted by the manufacturer.

Based on the fact that this coating is normally visible, it is likely that it had not been reapplied to the forward face during the last eddy current inspection. According to the overhaul manual for the MLG, Alocrom 1200 (or Alodine) must be applied on the forward face of the spigot housing during overhaul.APPH Ltd., Overhaul Manual 32-10-1, Overhaul Manual with Illustrated Parts List for Main Gear, Revision No. 20 (24 September 2025), Check, pp. 503, 505, and 507. In addition, a review of related SBs (SB 32-A-JA 851226,BAE Systems (Operations) Limited, Service Bulletin (SB) 32-A-JA 851226: Landing Gear – To Introduce NDT and Visual Inspections of Main Landing Gear Spigot Housing for Cracks, Revision 8 (12 November 2020), 2. Accomplishment Instructions, B. Accomplishment, Part B - Visual Inspection, p. 6. SB 32-19,Héroux Devtek, Service Bulletin (SB) 32-19: MLG Assembly – Inspect Cylinder Attachment Spigot Housing, Revision 9 (03 November 2020), 2. Accomplishment Instructions, B. Non-destructive Test, (6) Examination Standard, p. 5. SB 32-JM7862,BAE Systems (Operations) Limited, Service Bulletin (SB) 32-JM7862: Landing Gear – Introduction of Special Washer to Protect the Main Landing Gear Cylinder at the Forward Spigot, Revision 4 (11 January 2016), 2. Accomplishment Instructions, B. Accomplishment, p. 7. and SB 32-A-JA 140940BAE Systems (Operations) Limited, Service Bulletin (SB) 32-A-JA 140940: Landing Gear – Inspection of Main Landing Gear Special Washer Installation (03 October 2014), 2. Accomplishment Instructions, B. Accomplishment, Part 2, p. 7.) found that the reapplication of the chemical conversion coating is to be carried out on repaired areas on the forward face, where corrosion or wear marks (due to washer rotation) have been removed. There is no mention of reapplication of the chemical conversion coating according to visibility. Given that the zone from 7 o’clock to 5 o’clock was outside of the repaired area and that the cylinder was not being overhauled when the repair was performed, this zone did not have a requirement for recoating according to the SBs.

Even though the cracking occurred at the 12 o’clock location on the forward face of the spigot housing, the repair at the 6 o’clock position was also examined. It was found that the repaired area had not been coated with the coloured protective coating (chemical conversion coating), contrary to the instructions listed in SB 32-19. Although the absence of coating on the repaired area did not play a role in the failure of the MLG unit, if the coating omission is repeated during other MLG repairs, it could lead to pitting, stress corrosion cracking (SCC), and subsequent MLG failures.

In addition to the chemical conversion coating on the spigot housing’s forward face, outside of the repaired area, randomly and uniformly distributed wear marks were also present on this surface, and the manufacturer noted that the surface did not meet the surface finish specification. The overhaul manual specifies that the surface roughness of the spigot housing’s forward face should be at least 0.000016 inchesAPPH Ltd., Overhaul Manual 32-10-1, Overhaul Manual with Illustrated Parts List for Main Gear, Revision No. 20 (24 September 2025), Check, p. 503. (0.00041 mm). However, the 4 SBs listed above do not specifically refer to this minimum required surface finish, nor do they provide guidance on the removal of wear marks caused by something other than the rotation of the washer. SB 32-A-JA 140940 simply specifies that if there is “evidence of wear marks that may have been caused by migration of the special washer,” all such marks are to be removed.BAE Systems (Operations) Limited, Service Bulletin (SB) 32-A-JA 140940: Landing Gear – Inspection of Main Landing Gear Special Washer Installation (03 October 2014), 2. Accomplishment Instructions, B. Accomplishment, pp. 6-7. Although the wear marks did not appear to have contributed to the formation of most of the corrosion pits, it is possible that the wear marks damaged the coating protection, exposing the base material to an environment conducive to the formation of pitting.

1.12.5 Additional publications referenced in service bulletins

The main SBs related to the maintenance of the Jetstream 3100 series MLG direct maintenance personnel to other references for further information.

For example, SB 32-A-JA 851226, in section K, provides the following references:

Héroux Devtek SB 32-19 Revision 9 or later.

APPH SB 32-40 Revision 1 or later.

Maintenance Manual (Jetstream Series 3100).

Maintenance Manual chapters 7, 24 and 32.BAE Systems (Operations) Limited, Service Bulletin (SB) 32-A-JA 851226: Landing Gear – To Introduce NDT and Visual Inspections of Main Landing Gear Spigot Housing for Cracks, Revision 8 (12 November 2020), 1. Planning Information, K. References, p. 3.

In the same SB, section L states:

The following aircraft manuals are affected by this ISB.

Jetstream Series 3100 aircraft;

Maintenance Manual.

Maintenance Schedule.

|Component Maintenance Manual.Operators are requested to advise the Business Support Team, BAE SYSTEMS

(Operations) Limited, Prestwick International Airport, Ayrshire, KA9 2RW, SCOTLAND, of the accomplishment of this ISB and request the necessary revisions for the affected manuals.Ibid., L. Publications Affected, p. 3.

Similarly, section K (titled Other Publications Affected) in SB 32-19 states:

Recommended Maintenance Schedule Publication No. J/PSD/RMS/80.

NOTE This Service Bulletin amplifies the Special Instructions contained within the Recommended Maintenance Schedules, Section 3, Page 4, Para, 4.1.2, but does not constitute substitution for these Special Instructions.Héroux Devtek, Service Bulletin (SB) 32-19: MLG Assembly – Inspect Cylinder Attachment Spigot Housing, Revision 9 (03 November 2020), 1. Planning Information, K. Other Publications Affected, p. 2.

In order to comply with all requirements for maintenance (in this case, the maintenance of the MLG), it is necessary for maintenance personnel to reference or consult all maintenance publications. The SBs, maintenance manual, and maintenance schedule do not provide the specific requirements for the surface finish of the spigot housing’s forward face, nor do they discuss the specifications for the application of the chemical conversion coating, other than in a repaired area. It is only in the overhaul manual that the specific requirement for the surface roughness of the forward face can be found. As for the requirements for the visibility of the chemical conversion coating, they could not be found in any of the maintenance publications during the investigation.

The application of a chemical conversion coating following an eddy current inspection or a washer installation on a MLG ensures protection to the component’s base metal, delaying and possibly preventing the formation of corrosion pits. In this occurrence, although the wear marks did not appear to have contributed to the formation of most of the pits, it is possible that they damaged the coating protection, exposing the base material to an environment conducive to the formation of pitting.

1.12.6 Failure modes

Intergranular fracture of DTD 5094 aluminum is known to be caused by SCC; however, the dynamic testing carried out at the TSB Engineering Laboratory in Ottawa, Ontario, demonstrated that DTD 5094 can also fail intergranularly under impact loads. To determine which failure mode caused the intergranular fracture features, both SCC and intergranular overstress were considered.

SCC is a time-dependent failure mechanism that occurs when the following 3 conditions are met:

- a material susceptible to cracking is used;

- the material is exposed to tensile stresses; and

- the material is exposed to a corrosive environment.

SCC in DTD 5094 is a common issue that has been documented in multiple sources;BAE Systems (Operations) Limited, Service Bulletin (SB) 32-A-JA 851226: Landing Gear – To Introduce NDT and Visual Inspections of Main Landing Gear Spigot Housing for Cracks, Revision 8 (12 November 2020), 1. Planning Information, p. 1.,British Aerospace – Dynamics Division, Service Bulletin (SB) 32-36: Landing Gear – Main Gear – Fit Cylinder Manufactured from New Material (20 June 1988), p. 1.,United Kingdom Air Accidents Investigations Branch (AAIB), AAIB Bulletin 07/2015, G-GAVA, EW/C2014/08/02 (15 August 2014), p. 14.,McDonnell-Douglas Astronautics Company, SEM/TEM Fractography Handbook (Metals and Ceramics Information Center, 1975), pp. 50-53. therefore, the 1st condition is met. It is also likely that the spigot housing was exposed to tensile stresses in the form of service loads and tensile residual stresses (which are introduced during manufacturing and remain even when no external load is applied). Finally, the EDS analysis of the corrosion pits at the 12 o’clock position confirmed the presence of a corrosive environment within the aluminum. The presence of SCC was also supported by evidence of intergranular cracking present at various locations along the 3, 9, and 12 o’clock fracture surfaces.

Tensile and impact testing carried out found that intergranular features are inherent to fractures in DTD 5094 when it is exposed to impact loads, but not when it is loaded slowly in tension. Intergranular fracture due to overstress is an undesired failure mode because it consists of a severe reduction in grain boundary energy due to the segregation of metal or impurities along grain boundaries. In this case, it is unknown which kind of segregation caused the intergranular fracture due to overstress or whether the segregation occurred during manufacturing or over time as a result of environmental exposure. It is also unknown why the material partially fails intergranularly when exposed to dynamic loads but not when exposed to static loads.

The TSB laboratory determined that it is likely that a corrosive environment entered the MLG unit’s spigot housing at the overstress anomaly and the 4 corrosion pits and associated fatigue zones. These features are all well below the 6 mm critical crack length. In addition, there is metallurgical evidence of intergranular cracking at this location. Therefore, it is likely that the failure mode transitioned to SCC. SCC then propagated within the spigot housing, and the cracking likely progressed not only during landings, but also when the aircraft was parked. At some point, the amount of pre-failure cracking (a combination of the overstress anomaly, corrosion pits, fatigue cracking, and SCC) reduced the component strength to the point where the intact structure could not support the landing loads, and a final failure occurred in the form of ductile and intergranular fracture.

Owing to the fact that a distinction could not be made between the cracks caused by intergranular overstress and those caused by SCC, it is unknown how large the SCC cracks were before the failure and whether they had breached the surface enough to be detectable using existing inspection methods.

1.12.7 Eddy current inspection

Eddy current inspection is a technique that uses electromagnetic induction to identify a variety of physical, structural, and metallurgical conditions in a component. This requires that the component be made of electrically conductive ferromagnetic and nonferromagnetic metal parts. The inspection relies on a probe that is placed near the component, introducing a changing magnetic field to the conductive material. The changing magnetic field induces eddy currents within the material, and the flow of these eddy currents is disrupted by the material’s discontinuities. These changes in eddy currents are detected and then interpreted on a flaw detector screen so that the nature of these discontinuities can be analyzed.

The eddy current inspection method is well suited to find cracks, voids, and inclusions. Although it can detect subsurface defects (that is, those not open to the surface), this capability is limited. When the frequency of the eddy currents is increased, both their sensitivity and their ability to detect small defects are also increased, but their ability to detect subsurface defects is decreased or eliminated.

When an eddy current inspection technique is developed, such as the technique in SB 32-A-JA 851226, a minimum crack size is identified based on the equipment being used and the type of defect that is intended to be detected. The eddy current inspection technique developed for the spigot housing was intended to detect cracks that were a minimum of 1.27 mm (0.05 inches) in length or corrosion pits that measured a minimum of 1.27 mm long and 0.13 mm (0.005 inches) deep. However, depending on the location of the defects, they may go undetected if they do not exceed both of these specifications.

1.12.7.1 Eddy current inspection requirements for the main landing gear

To satisfy the requirements of EASA AD 2016-0224, BAE Systems SB 32-A-JA 851226, Héroux Devtek SB 32-19, and APPH SB 32-40 must all be consulted and followed.

In addition to providing instructions with respect to how often the eddy current inspection is to be carried out on the MLG spigot housing, SB 32-A-JA 851226 also provides instructions for preparing the aircraft for this inspection. For the eddy current inspection to be accomplished, the aircraft must be made safe and placed on jacks, with the MLG and special washer (post-modification SB 32-JM7862) removed from the aircraft. The eddy current inspection must be completed in accordance with SB 32-19 and reassembled once any required repairs have been made.

SB 32-19 lists the minimum requirements for the equipment and provides instructions for both the set-up of the instrumentation and calibration and the carrying out of the eddy current inspection. The areas to be inspected are to be cleaned, and if any of the protective finish shows signs of lifting or cracking, the areas are to be cleaned back to the bare metal. The forward and rear faces of the spigot housing as well as the forward and rear machined flat surfaces are to be inspected (Figure 9).

At the beginning of the inspection, a standard reference sample must be used to establish the sensitivity of the tester for that specific inspection. This standard reference sample serves as a calibration standard and has a human-made discontinuity (a 0.5 mm [0.02 inches] slot) in it. The eddy current inspection technique for the spigot housing must be capable of resolving (indicating) the 0.5 mm discontinuity on the reference sample at the required level of sensitivity.

As previously stated, the inspection technique is intended to detect cracks 1.27 mm or greater in length and corrosion pits 1.27 mm long by 0.13 mm deep or greater on the spigot housing faces or the machined flats.

Using the calibration standard with the 0.5 mm slot, the equipment settings are adjusted to obtain a vertical displacement of 80% full screen height when the probe slides over the slot. As stated in SB 32-19, “Any indication […] having an amplitude of 20% full screen height or greater that cannot be attributed to probe handling or component geometry shall be considered as a crack.”Héroux Devtek, Service Bulletin (SB) 32-19: MLG Assembly – Inspect Cylinder Attachment Spigot Housing, Revision 9 (03 November 2020), (5) Acceptance Criteria, p. 4.

1.12.7.2 Eddy current inspection of the main landing gear before the occurrence

On 13 December 2022, the MLG had undergone an eddy current inspection, conducted in accordance with SB 32-A-JA 851226, in order to meet the requirements of EASA AD 2016-0224. The results of the inspection indicated a corrosion pit at the 6 o’clock position; the depth of this corrosion pit was 0.51 mm (0.02 inches). This defect was repaired by being blended out in accordance with SB 32-19, which permits the repair of small cracks measuring a maximum depth of 2.54 mm (0.1 inches) from the face of the spigot housing.Ibid., (6) Examination Standard, p. 5.,Ibid., Figure 2: Local Repair, p. 8. The eddy current inspection was then carried out again; no other defects were noted.

When this defect was initially discovered, NWAL hired an NDT company, Cougar NDE Ltd., to verify the inspection. NWAL often hired Cougar NDE Ltd. to conduct these eddy current inspections.

In addition to conducting an inspection at 500 kHz, the frequency stated in the instructions presented in SB 32-19, Cougar NDE Ltd. also carried out the eddy current inspection at 200 kHz, given that deeper defects can be detected at this frequency. No other defects were noted.

1.12.7.3 Evaluation of past eddy current inspections

Eddy current NDT inspection methods that had been used on the MLG unit before the occurrence were evaluated at the TSB Engineering Laboratory. During this evaluation, the corrosion pits observed on the forward face of the spigot housing were all below 1.27 mm (0.05 inches) in length, the minimum crack length that these inspection methods were intended to detect.

In the case of the overstress anomaly, there is clear evidence (based on observations of the dark circular feature) that it grew radially from its initial size, and it appeared to have breached the top surface of the spigot housing. Because of some post-failure wear damage, it was difficult to determine the exact size of the crack that breached this surface. However, it appeared that the crack had a breach length of approximately 0.046 mm (0.002 inches), which is below the 1.27 mm detectability limit of the inspection technique.

The application of the eddy current inspection technique on the 1.6 mm (0.06 inches) surface crack adjacent to the 12 o’clock fracture was also examined. The presence of sealant in approximately half of the length of the crack (0.8 mm, or 0.03 inches) indicated that a crack of at least 0.8 mm in length had been present before the last washer installation, which coincided with the last time the MLG was removed from the aircraft for eddy current inspection.

1.13 Medical and pathological information

There was no indication that the performance of the captain or the FO had been negatively affected by medical or physiological factors, including fatigue.

1.14 Fire

There was no fire either before or after the occurrence.

1.15 Survival aspects

Not applicable.

1.16 Tests and research

1.16.1 TSB laboratory reports

The TSB completed the following laboratory reports in support of this investigation:

- LP069/2023 - NVM Recovery – Flight Tracker

- LP076/2023 - Main Landing Gear Failure

- LP094/2023 - CVR Audio Recovery

- LP122/2023 - Main Landing Gear NDT Evaluation

1.17 Organizational and management information

NWAL is based in Fort Smith, Northwest Territories, and at the time of the occurrence, it held an air operator certificate issued by TC for the following operations: aerial work (CARs Subpart 702), air taxi operations (CARs Subpart 703), and commuter operations (CARs Subpart 704). NWAL operated a fleet of single- and multi-engine aircraft and provided chartered and daily scheduled flights to northern communities in Alberta and the Northwest Territories. In January 2025, NWAL shut down its CARs Subpart 704 flight operations.

NWAL also holds an approved maintenance organization certificate that authorizes it to conduct maintenance on its fleet of aircraft. Under the certificate, it is authorized to carry out the required eddy current inspections.

1.18 Additional information

1.18.1 History of main landing gear failure on the Jetstream Model 3112

This occurrence is the 1st accident in Canada in which the Jetstream Model 3112 MLG failed due to SCC and intergranular overstress. Globally, to date, there have been several reported Jetstream 3100 series aircraft accidents involving the failure of the MLG as a factor (Appendix A).

1.18.2 Current airworthiness directives and service bulletins related to the main landing gear in Jetstream 3100 series aircraft

The current AD and SBs related to the NDT inspection of the MLG and to concern regarding SCC and intergranular overstress are listed below. The AD references 2 SBs, which each also reference multiple SBs, as follows:

- EASA AD 2016-0224: Landing Gear – Main Landing Gear – Inspection / Replacement

- BAE Systems SB 32-A-JA 851226 (Revision 8)

Title: Landing Gear – To Introduce NDT and Visual Inspections of Main Landing Gear Spigot Housing for Cracks- Héroux Devtek SB 32-19 (Revision 9)

Title: MLG Assembly – Inspect Cylinder Attachment Spigot Housing

Description: provides instructions for the eddy current NDT inspection - APPH SB 32-40 (Revision 1)

Title: Landing Gear – Main Gear – Inspect Cylinder Web for Cracks

Description: provides inspection instructions for a MLG with microswitch holes and is therefore not applicable to the occurrence MLG - BAE Systems SB 32-JA880340 (original issue)

Title: To Introduce Main Landing Gear Cylinders Manufactured from L161 Material

Description: optional guidance - BAE Systems SB 32-JM7862 (Revision 4)

Title: Landing Gear – Introduction of Special Washer to Protect the Main Landing Gear Cylinder at the Forward Spigot

Description: provides guidance for the installation of the tabbed washer

- Héroux Devtek SB 32-19 (Revision 9)

- SB 32-JM7862

- BAE Systems SB 32-A-JA 140940 (original issue)

Title: Landing Gear – Inspection of Main Landing Gear Special Washer Installation - SB 32-A-JA 851226

- SB 32-JA 880340

- BAE Systems SB 32-A-JA 140940 (original issue)

- BAE Systems SB 32-A-JA 851226 (Revision 8)

Two additional SBs related to the NDT inspection are:

- Héroux Devtek SB 32-56 (Revision 4)

Title: Landing Gear – Main Gear – Inspect Pintle to Cylinder Interface for Cracks - BAE Systems SB 32-JA960142 (Revision 5)

Title: Landing Gear – Main Gear – To Introduce Repeat Inspection of Pintle to Cylinder Interface for Cracks

2.0 Analysis

The investigation did not identify any operational or weather-related issues, nor did it find any mechanical problems with the aircraft other than the one involving the failed main landing gear (MLG) unit. The analysis will therefore examine the metallurgical factors that led to the collapse of the left MLG unit and the ability of the current non-destructive testing inspection technique to detect cracks in the MLG’s structure before they expand to the critical crack length.

2.1 Main landing gear failure

A corrosive environment likely entered the spigot housing of the left MLG unit at the overstress anomaly (the dark circular feature) and the 4 corrosion pits and associated fatigue zones. Evidence of intergranular cracking appeared at all 3 fracture locations in the spigot housing, and it is likely that the failure mechanism transitioned to stress corrosion cracking (SCC).

SCC is a time-dependent failure mechanism that occurs when the following 3 conditions are met: a material susceptible to cracking is used, the material is exposed to tensile stresses, and the material is exposed to a corrosive environment. It is also likely that the spigot housing was exposed to tensile stresses in the form of service loads and tensile residual stresses (which are introduced during manufacturing and remain even when no external load is applied).

SCC then propagated within the component, and the cracking likely progressed not only during landings, but also when the aircraft was parked. The amount of pre-failure cracking (caused by the combination of the overstress anomaly, corrosion pits, fatigue cracking, and SCC) eventually reduced the strength of the spigot housing to the point where the intact structure of the MLG unit failed in the form of ductile and intergranular fracture.

Finding as to causes and contributing factors

During the aircraft’s landing, several cracks in the spigot housing of the left MLG unit grew, to the point where the structure of the MLG unit failed. The cracks likely propagated because the material used was susceptible to SCC, and it was exposed to both tensile stress and a corrosive environment.

2.2 Service bulletin compliance

During the investigation, it was found that the requirements in Service Bulletin (SB) 32-19 for the application of chemical conversion coating to the forward face of the spigot housing and those for the surface finish of this surface were not followed.

Following the occurrence, the manufacturer, BAE Systems (Operations) Limited, noted that the chemical conversion coating was not visible on the forward face of the spigot housing. However, according to 4 SBs related to the maintenance of the MLG, the reapplication of chemical conversion coating during an inspection is required only on repaired areas, where the coating has been removed during the removal of corrosion or wear marks left by an inadvertently rotating washer. Nothing is stated about the coating being visible, nor is this specified as a requirement.

The metallurgical examination performed after the occurrence showed that the chemical conversion coating, though not visible, was present in the areas of the 3 fracture surfaces (at the 3, 9, and 12 o’clock positions) but was not in the 6 o’clock area, which had been repaired. Although the guidance provided in SB 32-19 states that repaired areas, where the protective treatment has been removed, must be reprotected using a coloured chemical conversion coating, this coating was not reapplied to the repaired area at the spigot’s 6 o’clock position.

Finding as to risk

If repair instructions contained within an SB are not explicitly followed, there is a risk that the repair will be ineffective and the respective part will fail prematurely.

The manufacturer also noted that the forward face of the spigot housing did not meet the surface finish specification. Although the overhaul manual provides a specific required surface roughness of the forward face (a minimum of 0.00041 mm, or 0.000016 inches), the 4 SBs do not specify this minimum required surface finish. SB 32-A-JA 140940 simply specifies that rework is necessary if wear marks that may have been caused by migration (rotation) of the washer are present.

The investigation determined that in order for maintenance personnel to find these specific requirements with respect to chemical conversion coating visibility and the minimum required surface roughness, it is necessary for them to reference several documents other than the main SBs.

Finding as to risk

If SBs do not provide specific details, such as the requirements for chemical conversion coatings and the minimum required surface finish, the issue identified in the SB may not be adequately addressed.

2.3 Eddy current inspection

When an eddy current inspection technique is developed, a minimum crack size is determined based on the equipment being used and the type of defect that is intended to be detected. The eddy current inspection technique developed for the spigot housing and outlined in SB 32-19 was intended to detect cracks that were a minimum of 1.27 mm (0.05 inches) long or corrosion pits that were a minimum of 1.27 mm long and 0.13 mm (0.005 inches) deep. However, depending on the location of the defects, those that do not meet both of these minimum sizes may remain undetected. The fracture at the 12 o’clock position started at the overstress anomaly, which was later observed on the fracture surface, as a dark circular feature. This overstress anomaly expanded, and the resulting crack appeared to have breached the top surface. It was determined that the length of this crack was under the 1.27 mm minimum crack length that the inspection process was intended to detect.

Finding as to causes and contributing factors

The required eddy current inspection method described in the SB was unable to detect the defects observed on the occurrence spigot housing. As a result, these defects remained undetected during service and contributed to the failure of the spigot housing.

3.0 Findings

3.1 Findings as to causes and contributing factors

These are the factors that were found to have caused or contributed to the occurrence.

- During the aircraft’s landing, several cracks in the spigot housing of the left main landing gear unit grew, to the point where the structure of the main landing gear unit failed. The cracks likely propagated because the material used was susceptible to stress corrosion cracking, and it was exposed to both tensile stress and a corrosive environment.

- The required eddy current inspection method described in the service bulletin was unable to detect the defects observed on the occurrence spigot housing. As a result, these defects remained undetected during service and contributed to the failure of the spigot housing.

3.2 Findings as to risk

These are the factors in the occurrence that were found to pose a risk to the transportation system. These factors may or may not have been causal or contributing to the occurrence but could pose a risk in the future.

- If repair instructions contained within a service bulletin are not explicitly followed, there is a risk that the repair will be ineffective and the respective part will fail prematurely.

- If service bulletins do not provide specific details, such as the requirements for chemical conversion coatings and the minimum required surface finish, the issue identified in the SB may not be adequately addressed.

4.0 Safety action

4.1 Safety action taken

4.1.1 BAE Systems (Operations) Limited and APPH

As a result of the occurrence, the manufacturer, BAE Systems (Operations) Limited, published Electronic Service Information Leaflet 32-J31-820-1, titled Corrosion Protection and Maintenance of the Jetstream 31 MLG Forward Pintle End Face,BAE Systems (Operations) Limited, Electronic Service Information Leaflet 32-J31-820-1: Corrosion Protection and Maintenance of the Jetstream 31 MLG Forward Pintle End Face (09 September 2024). highlighting the requirement for corrosion protection and the polishing of the spigot housing end face.

Revision 9 of BAE Service Bulletin (SB) 32-A-JA 851226BAE Systems (Operations) Limited, Service Bulletin (SB) 32-A-JA 851226: Landing Gear – To Introduce NDT and Visual Inspections of Main Landing Gear Spigot Housing for Cracks, Revision 9 (04 October 2023). and Revision 10 of APPH (Heroux Devtek) SB 32-19Héroux Devtek, Service Bulletin (SB) 32-19: MLG Assembly – Inspect Cylinder Attachment Spigot Housing, Revision 10 (04 October 2023). were also issued to address the required finish and the re-protection requirements for the end face of the spigot housing.

This report concludes the Transportation Safety Board of Canada’s investigation into this occurrence. The Board authorized the release of this report on 17 December 2025. It was officially released on 14 January 2026.

Appendices

Appendix A – Previous main landing gear failures on Jetstream 3100 series aircraft

Date | Aircraft registration | Occurrence summary | |

|---|---|---|---|

04 January 2022 | HR-AYY | A Jetstream 3100 series passenger aircraft experienced a right main landing gear (MLG) unit collapse upon landing on Runway 07 at Juan Manuel Galvez International Airport, Honduras. The No. 2 propeller struck the runway surface. The aircraft veered off the right side of the runway and came to rest on soft ground. | |

15 August 2014 | G-GAVA | The aircraft’s left MLG unit failed shortly after it landed on Runway 20 at Doncaster Sheffield Airport, England. The left MLG unit detached from its mounts, and the aircraft slid along the runway on its remaining landing gear, left wing tip, and cargo belly pod before veering off the runway and coming to rest on the adjacent grass. The single passenger and the flight crew vacated the aircraft without injury. | |

08 March 2012 | G-CCPW | The aircraft’s right MLG unit failed as the aircraft landed on Runway 26 at Isle of Man Airport. The right MLG unit detached, and the aircraft slid along the runway on its remaining landing gear units, right wing tip, and cargo belly pod. It came to rest on the grass adjacent to the runway. The passengers and flight crew vacated the aircraft without injury. The final failure was initiated as a result of stress corrosion cracking in the forward portion of the spigot housing at the top of the right MLG leg. One Safety Recommendation was made by the United Kingdom Air Accidents Investigations Branch. | |

12 February 2009 | SX-SKY | After a Jetstream 3100 series aircraft had covered a distance of approximately 80 m on the runway while landing at Nikos Kazantzakis Airport, Greece, the right MLG unit collapsed, folding backwards, and the right propeller came into contact with the runway. After a further distance of 930 m, which the aircraft covered with its left MLG unit operating normally but with its collapsed right MLG unit being dragged along the runway, the aircraft came to a stop 4.6 m to the right of the runway centreline. | |

1980 | XX 493 | On a Jetstream 3100 series aircraft operated by the United Kingdom Royal Air Force, a crack 127 mm long was discovered during unrelated work. The crack appeared to have originated from a number of intergranular corrosion cracks growing from the outer edge of the spigot housing. Fatigue banding was found at the end of these cracks. Photographs of the crack, after it had been opened, show evidence of dark staining similar to that seen on the failed spigot housing fitted to G-CCPW. Two years before the discovery of the crack, the aircraft had been used for crosswind landing trials. | |

1985 | XX 491 | On a Jetstream 3100 series aircraft operated by the United Kingdom Royal Air Force, a crack approximately 160 mm long was found in the spigot housing on the left MLG unit; the aircraft had had a runway excursion 5 months and 478 landings earlier. The crack initiated on the outer edge of the forward face of the spigot housing and extended along the upper machined face for 130 mm when it then split into 2 branches that were 25 and 30 mm long. There was no evidence of fatigue, and the failure did not appear to have been caused by overstress produced by a heavy landing. Examination of the crack found evidence of intergranular cracking and exfoliation along the inside of the bore, halfway along the crack. In addition, there was a “dried mud” feature at the start of the fracture. | |

1987 | XX 491 | A crack approximately 120 mm long was found in the forward spigot housing in the landing gear that had been installed following the discovery of the crack in the 1985 occurrence. The investigation determined that the new crack was caused by stress corrosion cracking (SCC) and that the crack originated at the outer corner of the end face of the spigot housing. There was no evidence of the “dried‑mud” feature that had been observed during the previous occurrence. It was believed that the SCC probably extended for no more than 5 mm and then resulted in a subsequent rapid failure from a dynamically applied load. The investigation also concluded that a breakdown of the corrosion protection allowed inter-crystalline corrosion to propagate with subsequent crack propagation by SCC. The MLG unit had flown a total of 10 289 landings and had last been overhauled 9 months and 2622 landings before the discovery of the crack. During overhaul, corrosion had been removed from the end face of the spigot housing. The last eddy current inspection had been carried out 31 flights previously. | |

Unknown | XX 494 | As a result of the 1984 findings on the occurrences involving XX493 and XX491, the United Kingdom Royal Air Force inspected the spigot housings on another Jetstream 3100 series aircraft using an eddy current inspection technique. The examination revealed small defects on the forward face of the spigot housing on both MLG cylinders that had resulted from “end grain” corrosion. The examination also found that the protective treatment (anodized layer) on the face of the spigot housing had been worn away. | |

![Figure 3. Schematic diagram showing the main components of the main landing gear unit (Source: APPH Ltd., Overhaul Manual 32-10-1, Overhaul Manual with Illustrated Parts List for Main Gear, Revision No. 20 [24 September 2025], Description, Operation and Data, p. 2, with TSB annotations) Figure 3. Schematic diagram showing the main components of the main landing gear unit (Source: APPH Ltd., Overhaul Manual 32-10-1, Overhaul Manual with Illustrated Parts List for Main Gear, Revision No. 20 [24 September 2025], Description, Operation and Data, p. 2, with TSB annotations)](/sites/default/files/2026-01/A23W0039-figure-03-ENG.jpg)

![Figure 9. Areas to be inspected by eddy current (highlighted in yellow) on the spigot housing (Source: Héroux Devtek, Service Bulletin [SB] 32-19: MLG Assembly - Inspect Cylinder Attachment Spigot Housing, Revision 9 [03 November 2020], Figure 1: Areas of Inspection, p. 7, with TSB annotations) Figure 9. Areas to be inspected by eddy current (highlighted in yellow) on the spigot housing (Source: Héroux Devtek, Service Bulletin [SB] 32-19: MLG Assembly - Inspect Cylinder Attachment Spigot Housing, Revision 9 [03 November 2020], Figure 1: Areas of Inspection, p. 7, with TSB annotations)](/sites/default/files/2026-01/A23W0039-figure-09-ENG.jpg)