Stall at takeoff and collision with water

Conair Group Inc. (dba Conair)

Air Tractor AT-802A Fire Boss Amphibian, C-GXNX

Chantslar Lake, British Columbia

The Transportation Safety Board of Canada (TSB) investigated this occurrence for the purpose of advancing transportation safety. It is not the function of the Board to assign fault or determine civil or criminal liability. This report is not created for use in the context of legal, disciplinary or other proceedings. See Ownership and use of content. Masculine pronouns and position titles may be used to signify all genders to comply with the Canadian Transportation Accident Investigation and Safety Board Act (S.C. 1989, c. 3).

Summary

An Air Tractor AT-802A on amphibious floats (registration C-GXNX, serial number AT-802A-0530), operating as Tanker 685, was carrying out wildfire management operations during daylight near Chantslar Lake, British Columbia. Three similar aircraft were working as a group with Tanker 685, which was second in line on a touch-and-go to scoop water from Chantslar Lake. Upon liftoff, control was lost and the aircraft’s right wing struck the water. The aircraft water-looped, and the floats and their support structure separated from the fuselage. The aircraft remained upright and slowly sank. The pilot received minor injuries, egressed from the cockpit, and inflated the personal flotation device being worn. The third aircraft in the formation jettisoned its hopper load as it continued its takeoff and remained in the circuit. The fourth aircraft jettisoned its hopper load, rejected its takeoff, and taxied to pick up the accident pilot. There was sufficient impact force to activate the on-board 406-megahertz emergency locator transmitter, but the search-and-rescue satellite system did not detect a signal from the emergency locator transmitter until the wreckage was being recovered 6 days later.

Factual information

1.1 History of the flight

The aerial firefighting operation involved 5 aircraft: a Bird Dog (Cessna 208 Caravan) and 4 single-engine air tankers (SEATs) on amphibious floats (Air Tractor AT-802A Fire Boss). The accident aircraft, an Air Tractor AT-802A on amphibious floats (registration C-GXNX, serial number AT-802A-0530), was operating as Tanker 685 (T685). The Bird Dog crew (made up of a pilot and an air attack officer) planned and directed the fire suppression activity. The group of 4 tanker aircraft carried out a circuit-like pattern in formation between the fire and Chantslar Lake (5 nautical miles [nm] south).

The first flight of the day consisted of 25 scooping runs, dropping a total of 100 loads of fire suppressant agent on the same fire. The group had stopped at 1415 Footnote 1 to refuel and take a lunch break at the Puntzi Mountain Aerodrome (CYPU), 16 nm east of Chantslar Lake, and departed at 1630 with full fuel and full foam Footnote 2 for the second flight of the day. The plan was for the tanker group to continue the same operation.

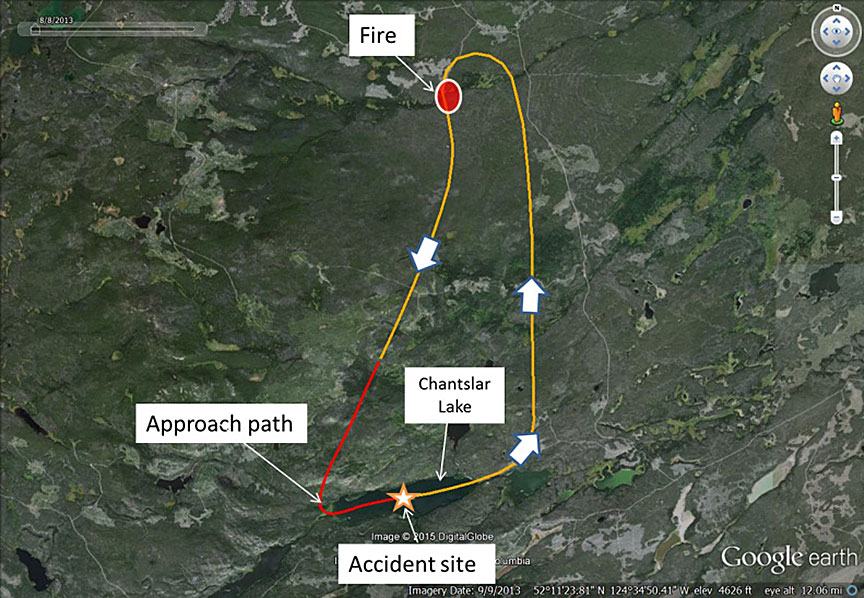

Global positioning system (GPS) data showed that T685 touched down for the accident scooping run at 0.25 nm from the southwest end of the lake (Figure 1) and maintained an average heading of 076° magnetic (M) for 0.75 nm. The ground speed gradually increased and remained steady at 71 knots for about 4 seconds before the aircraft decelerated and came to a near stop 2 seconds later. The accident occurred halfway down the lake, after the aircraft had been on the water for approximately 44 seconds.

Calculations based on GPS data, density altitude, true airspeed, and wind allowance determined that T685 had lifted off at a speed equivalent to 67 knots indicated airspeed (KIAS). The liftoff speed was 6 knots below the published power-off stall speed of 73 KIAS.

The accident scooping run was conducted in accordance with Conair standard operating procedures (SOPs). The flaps were selected to about 20°, and the scooping probes (1 in each float) were extended after the aircraft was on the water and were set to retract automatically when the pilot-selected load level was achieved. Full takeoff power was applied during the scooping run, to keep the floats planing on the water while loading the hopper and to accelerate to liftoff speed after the probes retracted.

Moments after liftoff, control of the aircraft was lost as the aircraft rolled to the right, and the right-hand wing tip contacted the water. The aircraft then yawed further to the right, rolled to the left, and pitched down before the front outboard side of the left float contacted the water again. The aircraft remained right-side-up and came to rest on a northerly heading.

The accident occurred at 1741 during the thirteenth scooping run of the second flight (thirty-eighth scoop of the day), moments after liftoff.

1.2 Injuries to persons

The pilot received minor injuries to the left hand and an abdominal bruise. The pilot was wearing a helmet, a personal flotation device (PFD), and a 4-point safety harness. In addition, the aircraft was equipped with a portable emergency air supply (helicopter emergency egress device), which was not required in this case.

1.3 Damage to aircraft

The aircraft was substantially damaged and was assessed as beyond economical repair.

1.4 Other damage

None.

1.5 Personnel information

Records indicate that the pilot was certificated for the flight in accordance with existing regulations. The pilot had been seasonally employed by the operator since 2007 and had completed type-specific pilot competency training on the AT-802A annually since May 2008. This training was last completed in April 2014. Non type-specific training included safety management systems (SMS) and pilot decision making, which were completed in March 2014.

The group's duty day began at about 0930 and included a 2-hour-and-15-minute refuel and lunch break from 1415 to 1630. A review of duty schedules and the 72-hour history for the accident pilot did not identify fatigue as a factor.

| Pilot licence | Airline transport pilot licence - Aeroplane (ATPL-A) |

|---|---|

| Medical expiry date | 01 April 2015 |

| Total flying hours | 7500 (3300 on floats) |

| Hours on type | 1200 |

| Hours on type in 2014 | 165 (approx. 1000 scoops) |

| Hours on type in the previous 3 days | 17 |

| Hours on duty prior to the occurrence | 8.2 |

| Hours off duty prior to the work period | 13.5 |

1.6 Aircraft information

1.6.1 General

The Air Tractor AT-802A is advertised to be the world's largest single-engine aircraft. The aircraft is a single-seat, low-wing design manufactured with a standard tail-wheel style of undercarriage and intended specifically for the agricultural role. The design was certificated in Canada in the restricted classification and operates under a Special Certificate of Airworthiness—Restricted. This means that the aircraft has been shown to conform to its type design and found to be safe for flight when operated within the limitations and prohibitions specified for its intended use. It has not been shown to comply with Canadian airworthiness standards or with International Civil Aviation Organization airworthiness standards.

Air Tractor offers several choices of Pratt & Whitney Canada PT6A engine models. T685 was delivered from the factory with a PT6A-67F model, which developed a takeoff power of 1424 shaft horsepower (SHP) to a Hartzell, 5-bladed, fully reversing propeller. The aircraft has a maximum takeoff weight (MTOW) of 16 000 pounds. The hopper, Footnote 3 located between the cockpit and the engine, has a capacity of 3028 litres.

Fuel tanks are installed in the wings; T685 had a useable fuel capacity of 1416 litres. There was also a 68-litre capacity storage tank for foam concentrate in the engine compartment forward of the hopper and a foam concentrate tank of 113 litres in the right-hand float.

The factory version of the aircraft was modified by several supplemental type certificates (STCs) for the firefighting role. The 2 primary STCs were:

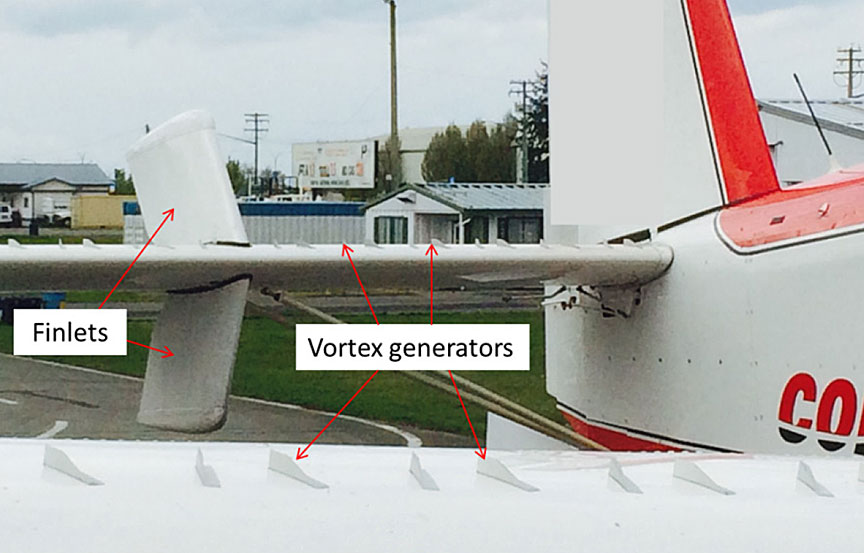

- the Fire Boss conversion (Photo 1), which included the installation of the amphibious floats and stall performance enhancements (known as a stall improvement array); and

- a power upgrade, which increased the maximum takeoff power to 1600 SHP.

1.6.2 Weight and balance

It is Conair's unwritten policy, conditions permitting, for scooping flights to take off at the aircraft's MTOW in order to deliver maximum value to the client. Pilots carry a quick reference chart, produced by the company, which allows them to easily adjust the hopper load to compensate for fuel and foam concentrate consumed throughout a flight so as not to exceed the MTOW.

As part of the investigation, the weight and balance were calculated to reflect the expected operating configuration. No data were available to determine the actual hopper load; there was no information to indicate that the aircraft exceeded the MTOW limitation at the time of the accident. Allowing for fuel consumed, and assuming that the delivery of 12 loads of suppressant consumed half of the foam concentrate and windshield washer fluid, and that the hopper was filled to bring the weight at takeoff to 16 000 pounds, the centre of gravity (CG) would have been located 26.8 inches aft of the datum at the time of the accident. The aft CG limit at 16 000 pounds is 27.0 inches aft of the datum. The CG was within allowable limits at the time of the accident.

1.6.3 Aircraft performance

1.6.3.1 Float operations (general)

When a typical, normal certification float-equipped aircraft is planing on the water, the pilot can pitch the aircraft a few degrees nose-up and nose-down to identify the sweet spot of the floats. This is the attitude of least water resistance and greatest acceleration. Pitching the aircraft beyond the sweet spot in either direction causes noticeable deceleration. Pilots are normally limited to operating at pitch angles within the sweet spot for water takeoffs.

1.6.3.2 Wipaire supplemental type certificate SA03-54 (Fire Boss float installation)

The Wipaire Wipline model 10000 float is based on the model 13000 float design. Modifications to the model 13000 floats were required to improve the takeoff performance by shortening the float afterbody, which allows the aircraft a greater range of pitch-up capability on the water. The scooping and foam concentrate tank assemblies as well as airframe-mounted operating controls and components were installed.

Additional airframe modifications were found to be necessary to return the aircraft flight performance characteristics to regulatory standards in the restricted category. These modifications, collectively known as a stall improvement array, principally included the installation of finlets on the top and bottom of the horizontal stabilizers, a ventral fin under the empennage, and vortex generators on the wings and horizontal stabilizers (Photo 2). In addition, the pitot tube was relocated further outboard and the stall warning vane was repositioned.

Performance data included in the Wipaire airplane flight manual supplement (AFMS) were determined with the PT6A-67F engine installed by Air Tractor flat-rated to 1350 SHP. The performance section in the AFMS indicates that the aircraft is capable of achieving or exceeding the minimum required climb gradient or rate of climb in accordance with the certification criteria at the MTOW of 16 000 pounds under the conditions existing at the time of the accident. Footnote 4 The AFMS limitations and performance charts do not account for the additional 250 SHP available after supplemental type certificate (STC) P-LSA08-072 (Power Increase Kit) was incorporated.

The stall improvement array installation resulted in a reduction of the stall speed. The AFMS shows the power-off stall speed to be 73 KIAS (instead of 83 KIAS) with flaps 20°, bank 0°, engine power set to flight idle, aircraft total weight of 16 000 pounds, and a most-aft-allowable CG location. The stall improvement array also resulted in a delay of the stall buffet until full wing stall occurs, with engine power applied.

Stall behaviour of the Fire Boss is described in the Wipaire AFMS as follows:

Stall characteristics of this airplane are overall quite docile. With power off or at low power, a strong buffet and tail shake will be noted at approximately the same time as the stall warning sounds. With higher power settings the buffet onset speed slows to near the stall speed . . . WARNING! Continued aft control stick movement after stall cues have developed with the slip indicator ball displaced from centre, particularly with power on, will result in a sharp roll off with attendant loss of altitude. Normal control usage will affect prompt recovery. Footnote 5

At airspeeds near the power-on stall, an existing condition is identified in the Wipaire AFMS:

Indicated airspeed values at the stall, especially with power applied are typically not very accurate or repeatable due to static pressure variations at the static ports. Footnote 6

Further:

For most aircraft relying on pitot-statics for airspeed determination, the indicated stall speed with power on is meaningless due to the very low speed and the inability to determine the position errors required to correct the speed back to a useful number. The AT802's airspeed [indicator] during a power on stall is not useable. Footnote 7

The Fire Boss was previously equipped with angle-of-attack (AOA) indicators, but Conair found them to be problematic and they were removed.

1.6.3.3 Conair supplemental type certificate P-LSA08-072, issue 5

The new aircraft, as received by Conair, was equipped with the Wipaire Fire Boss STC and the PT6A-67F engine model, but rated at 1424 SHP, which is an Air Tractor option.

With the 1424-SHP engine, the aircraft continued to meet the certification criteria for a restricted category aircraft, but operators wanted more power to improve the takeoff and climb performance. Conair developed an independent STC to increase the engine power to 1600 SHP. The MTOW remained the same at 16 000 pounds. The STC applied to the aircraft in the Fire Boss configuration only, and T685 was equipped with this STC.

The AFMS for the power-increase STC contains engine operating limitations for the higher-powered engine. It includes 3 advisory statements under Flight Limitations about the potential consequences of high-power stalls and skidding or slipping turns, Footnote 8 and 4 statements in the Performance section about the increased fuel consumption. Footnote 9 It also contains a statement that reads, “For Limitations, Procedures and Performance Data not contained in the Supplement consult the ‘Fire Boss' Flight Manual Supplement (SA03-54) and/or appropriate optional equipment supplements.” Footnote 10

Transport Canada (TC) airworthiness standards allow applicants for a performance-increase modification—in this case, a power increase from 1424 to 1600 SHP—to exercise the option of quantifying the increase in performance via flight test, or simply accepting the current performance, knowing that the performance resulting from incorporation of the STC will be equal to, or exceed, the current published performance. Conair chose to accept the performance data presented in the Wipaire AFMS (1350 SHP).

1.6.3.4 Aircraft stall performance

The following information regarding low-energy flight hazards is taken from the Conair company operations manual:

[S]talls are another problem to be wary of with operation in the region of reversed command. Since angles of attack are already high, a stall can occur on the overshoot, particularly if the exit requires immediate manoeuvring for terrain avoidance. In no other flying situation are the combinations of low energy flight, the region of reversed command and stall as intolerant of mishandling as in the low altitude, maximum performance operations typical of aerial firefighting. […] It is imperative that all operations are carefully orchestrated with crews alert, and approaches and exits carefully planned. Being aware of such hazards to low and slow flight will help to mitigate their effects. Footnote 11

The United States Federal Aviation Regulations and Canadian airworthiness design standards (paragraph 23.201(f)(5)(iii) require that turbine-powered airplanes demonstrate stalls under certain combinations of engine thrust and aircraft configuration. The demonstration of a full-power-on stall does not fall within the requirements. The full-power-on stall characteristics of the Fire Boss have not been determined.

The AT-802A Fire Boss is known for its stall characteristics with power off, and there are mandatory placards in the cockpit for pilot reference.

The STC P-LSA08-072, Issue 5, increased the SHP output to the propeller, which produces additional thrust and, therefore, slipstream over the tail surfaces and inboard sections of the wings. Like any powered aircraft with tractor-type propellers producing slipstream over the wings, this artificial airflow allows for a higher pitch-up attitude before a full stall and loss of control occurs. Since the outboard sections of the wings of a single-engine aircraft do not benefit from slipstream, these sections of the wings may be stalled even though the aircraft can lift off.

In 2008, flight tests with the same make and model of aircraft included stall characteristics with power on. Conair Engineering project report number 1-3173.5, Table 15 recorded the results of interest to this investigation related to the configuration of the aircraft at the time of the accident: 0° bank, 20° flaps, 16 000-pound takeoff weight, maximum takeoff power (1600 SHP), aft CG. The tests were limited to 50% maximum continuous power due to safety concerns at higher power settings. The results of the tests showed that the buffet and stall both occurred at 65 KIAS, and the stall warning activated at 75 KIAS. In addition, 6 tests were completed: 2 at the forward and 2 at the aft CG condition, with flap settings of 10°, 20°, and 30°. The results were as follows: 1 case did not produce any roll, 4 cases resulted in a roll of 20° to the right, and 1 case resulted in a roll of 30° to the right.

1.6.3.5 External factors affecting stalls

1.6.3.5.1 Ground effect

Ground effect is a phenomenon that is considered to occur when an aircraft is flying within 1 wingspan of the surface.

In general, ground effect reduces the wing downwash angle resulting in a lower AOA. This translates into […] a higher lift/drag ratio. Low wing aircraft are more susceptible to ground effects than high wing aircraft. […] When taking off [with] a low wing aircraft, it might be possible to attain flight in ground effect at weights or speeds that are not possible out of ground effect. Footnote 12

In this case, despite any potential benefits of ground effect, the aircraft had not climbed out of ground effect when the accident occurred. It was not determined whether ground effect had any influence on the sequence of events.

1.6.3.5.2 Wing-tip vortices

Wing tip vortices are generated by the same forces that provide lift to the airplane. High- pressure air beneath the wing flows outward around the wing tip into the low-pressure air above the wing flowing inward and forms a vortex behind each wing that counter-rotates Footnote 13 and descends behind the aircraft. The typical risk to a trailing aircraft encountering these vortices is an induced roll, which can exceed the control authority of the affected aircraft. Footnote 14

Wing-tip vortices are unpredictable. Many factors affect the size, intensity, longevity, and movement of these disturbances. Vortices are considered to be generated while an aircraft is airborne and the wings are generating lift; they are greatest behind slow and heavy aircraft. During takeoff and landing, the vortices tend to spread out over the surface behind the generating aircraft—opposite to the vortex rotation—and linger the longest in calm or light wind conditions.

Conair pilots encounter wake turbulence generated by wing-tip vortices on a regular basis and consider it a phenomenon worthy of respect. It is regarded by some as a normal part of everyday operations. Annual ground school training at Conair includes discussion of wing-tip vortices and methods to try to avoid wake turbulence encounters. However, despite the frequency of such encounters, some company's pilots have difficulty distinguishing the difference between a stall buffet and a wing-tip vortex encounter on takeoff.

1.6.4 Standard operating procedures—scooping operations

Aerial firefighting operations can be intense yet repetitive work conducted within a small team of single-pilot aircraft (e.g., repeated takeoffs at MTOW, in groups, dumping precisely, for long hours in forested areas, in dry summer weather).

When firefighting with the Fire Boss, Conair normally operates in teams of 4 aircraft, in a loose line-astern arrangement. During scooping operations, the pilots adjust their relative positions to suit local conditions such as the lake dimensions, wind, and terrain in relation to the target fire. Scooping in an echelon or upside-down “V” formation, as they were on the accident flight, is common (Photo 3). At the fire (drop site), the aircraft are at minimum 10 seconds apart, normally line astern.

According to Conair SOPs, the normal procedure for a scooping run is to touch down at about 60 KIAS Footnote 15 with scoops retracted and flaps set to 20°. Touchdown is accomplished with nose-up elevator trim and full-right rudder trim. Once the hopper fills to the selected volume, the scoops retract automatically—manual mode is not recommended—and a distinct acceleration can be felt. As the aircraft accelerates to 60 knots with the nose held up to reduce porpoising, a float‑normally the right-side one‑can be lifted with left roll control input and may be assisted by torque between the engine and propeller. The aircraft becomes airborne shortly after the first float breaks free of the water surface. The attitude on liftoff is nose high, respective wing low, with a momentary stall buffet. Once airborne, the wings are leveled, the nose is then lowered to remain in ground effect and the airspeed will increase to 80–85 knots when a positive climb can be initiated. Climb continues at 85 knots with 20° flap until obstacles are cleared. Footnote 16

The investigation did not find any documentation to verify that the technique of lifting 1 float before the other actually provides any benefit during the takeoff run. The Wipaire AFMS discusses scooping takeoffs but describes the liftoff segment as a “normal floatplane takeoff” without mention of this technique or suggestion of a target liftoff speed.

All company Air Tractor Fire Boss pilots had received the same ground school and flight training regarding stall characteristics and behaviour at altitude with power off. The investigation did not find any documentation or guidance regarding ground school training in stall behaviour for the aircraft in the takeoff configuration with full power applied.

Pilots had differing understandings of the aircraft capabilities. Some pilots do not use the technique of lifting 1 float off the water first, but rather accelerate, wings-level, on the water to a liftoff speed greater than the power-off stall speed for the airplane configuration, or reduce the load in order to achieve liftoff conditions that will reduce the risks of a wing stall.

1.6.5 Emergency locator transmitter

T685 was equipped with a Kannad 406 AF-COMPACT emergency locator transmitter (ELT), which operated on a frequency of 406 megahertz (MHz). There was sufficient impact force to activate the ELT, but the search-and-rescue satellite system (SARSAT) did not detect the signal until the wreckage was re-floated 6 days later. It is a common occurrence for submersion to attenuate the ELT distress signal.

1.7 Meteorological information

The Environment Canada weather site, located at the Puntzi Mountain Aerodrome, recorded the following conditions at 1700: temperature 31 °C, dew point 8 °C, wind 020° true (T) at 5 knots, station pressure 990.9 kilopascals (kPa) (29.26 inches of mercury [in. Hg]). The visibility was not recorded.

Conditions at 1800 were: temperature 29 °C, dew point 11 °C, wind 110°T at 9 knots, station pressure 990.88 kPa (29.26 in. Hg). The visibility was not recorded.

There is no official source of recorded weather data at Chantslar Lake; however, all 4 tanker pilots described the wind as 5 knots or less and variable in direction, generally from the east. The water was calm with a small ripple. Given the information obtained, a headwind allowance of 3 knots was made for the investigation of takeoff performance.

1.8 Aids to navigation

Not applicable.

1.9 Communications

Not applicable.

1.10 Aerodrome information

Chantslar Lake is located at 52°08.7934′N, 124°35.2925′W (16 nm west of the Puntzi Mountain Aerodrome) at an elevation of 3941 feet above sea level (asl). The lake is oriented 060/240°M and is about 1.95 nm in length by 0.38 nm wide. The density altitude at Chantslar Lake at the time of the accident was calculated to be about 7581 feet asl.

1.11 Flight recorders

The aircraft was not equipped with a cockpit voice recorder or a flight data recorder, nor was either required by regulation.

T685 was equipped with a global positioning system (GPS), which transmitted position reports to a remote site every 2 minutes. This system's non-volatile memory stores these positions as well as non-transmitted second-by-second positions for the last 2-minute period recorded. All of these data were recovered.

T685 was equipped with a data acquisition alarm monitor (DAAM) system, which principally monitored and recorded engine operating parameters. This unit was recovered, but no data were recovered from it.

1.12 Wreckage and impact information

During the accident sequence, the aircraft yawed to the right and water-looped. The forward section of the right-hand wing at the outboard end was crushed. Both floats and all attachments separated from the fuselage and the float attachments remained fixed to the floats, which were separated from each other and remained floating nearby. During the water-loop, the aircraft travelled backward through the water and came to rest about 270° off the original takeoff heading. The majority of the right-hand wing flap was missing. Otherwise, flight control surfaces were all accounted for.

The elevator trim was set to about 2/3 aft of neutral, the aileron trim was set to a neutral position, and the rudder trim was set to the nose-right end of the green takeoff arc. The wing flaps were extended to about 20°. The elevators were jammed in the full nose-up position, beyond the stops, and exhibited damage where contact occurred with the finlets on top of both horizontal stabilizers. The rudder had been pushed to the right side beyond its stops.

The aircraft itself sank and was recovered 6 days later. Before disassembly for transport, an initial examination was carried out and the flight controls were examined for continuity; no pre-existing defects were found. The left wing did not exhibit any damage except to the wing flap.

The propeller and the reduction gear box (RGB) detached from the engine during the impact sequence and were not recovered. The RGB detached at a circumferential fracture surface immediately forward of the engine exhaust duct attachment flange. The engine had continued to run and was shut down by the pilot. Visual examination of this fractured cast surface did not identify any sources of progressive fatigue, and it was not subjected to further examination. It was also observed that the engine exhaust duct was twisted, consistent with a high torque event while the engine was producing high power and the propeller encountered significantly higher than normal resistance. The engine power turbine (PT) blades did not fracture or exhibit signs of thermal damage.

At the time of the accident, the aircraft's total air time was recorded as 223 hours. No mechanical or technical deficiencies affecting the pre-impact airworthiness of the aircraft were identified.

1.13 Medical and pathological information

Not applicable.

1.14 Fire

Not applicable.

1.15 Survival aspects

Not applicable.

1.16 Tests and research

The operator estimates that since 2003, they have completed 100 000 scooping operations using the Fire Boss; the TSB database contains 7 reportable occurrences and 4 voluntary reports in Canada and 25 foreign entries concerning Air Tractor AT-802 models. Review of these 36 entries identified 1 accident Footnote 17 that may have some similarities to this accident. It involved an AT-802A Fire Boss, in position No. 4 of a 4-aircraft group that encountered multiple wake vortices that upset the aircraft while still on the water.

Conair Engineering project report number 1-3173.5, Table 15 recorded the test results of Fire Boss stall characteristics with partial power on. This testing is described in section 1.6.3.4.

1.16.1 TSB laboratory report

The following TSB laboratory report was completed in support of this investigation:

- LP174/2014 – Data recovery from Latitude Technologies GPS tracking unit and Perkins Technologies data acquisition and alarm monitor (DAAM)

1.17 Organizational and management information

1.17.1 Conair Group Inc.

Conair is a specialty aircraft operations provider that caters to national and international customers. The company employs about 250 people (including 80 pilots) and has a fleet of 65 fixed-wing aircraft. For the 2014 fire season, the Air Tractor fleet consisted of 14 AT-802A Fire Boss aircraft (on amphibious floats) and 11 AT-802A aircraft on wheels.

Firefighting makes up all of this operator's business. Although the operator uses several large aircraft types (MTOW of 12 500 pounds or greater), firefighting operations are carried out under CARs Part VII, Subpart 2 (aerial work). Operators under this subpart are not required to implement an SMS, but this operator did so voluntarily. TC conducted a process validation inspection (PVI) on this operator in November 2013; there were no findings. Since an SMS was not required, the company's SMS was not subject to TC oversight or inspections and, in accordance with that policy, was not included in the PVI.

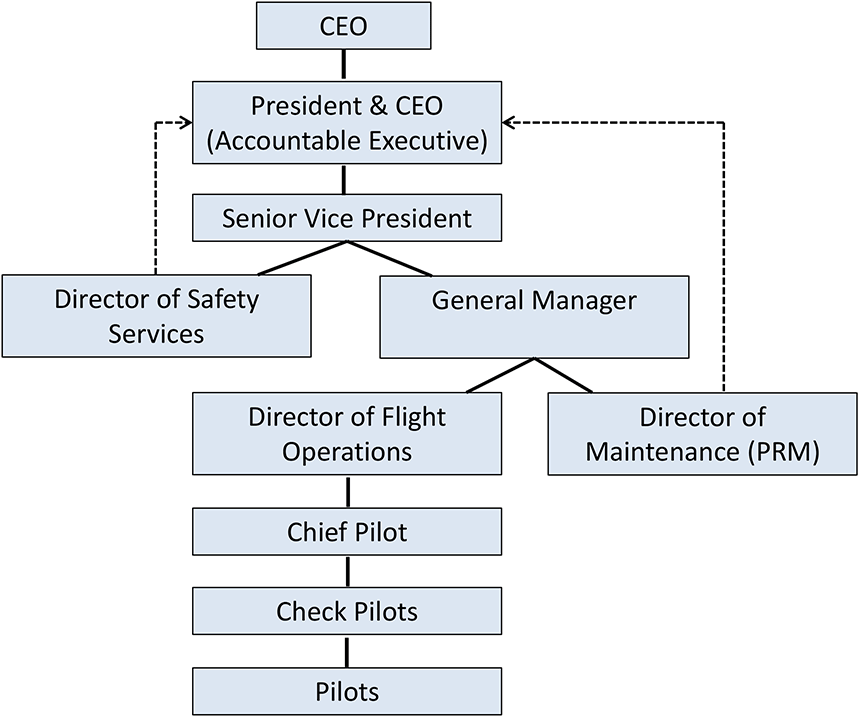

The company experienced significant organizational changes between 2010 and 2014. Its organization chart for 2010 identified 5 management levels, occupied by 5 people, above the company check pilot position, plus the director of safety services (DSS) (Appendix A, Figure 1). At that time, there were 3 check pilots supporting the chief pilot (CP).

During the 2011 and 2012 periods, Conair divested itself of another business entity, and a re-organization of the company management structure resulted in the removal of 2 levels of upper management. The director of flight operations (DFO) was also temporarily replaced, and the 3 company check pilot positions became vacant. In 2013, the director of safety services became the new DFO and continued to cover the vacated DSS position, with assistance from the quality assurance manager, until a suitable replacement could be found.

In 2014, company organization charts identified 3 management levels (Appendix A, Figure 2) above the company check pilot position. The company check pilot positions were replaced with type-training pilots identified as line check pilots; the AT-802 line check pilot happened to be assigned, as a full-time member, to the British Columbia group. The line check pilot did not have management or supervisory responsibilities; the role included leadership and mentorship as well as conducting check rides on other group members. Efforts to hire a new DSS continued and were successful in January 2014; however, this position was suddenly vacated again when the individual left the company in July 2014.

1.17.2 Introduction and evolution of the Fire Boss operation

Conair acquired 2 AT-802 aircraft on wheels in 1996 to try out the single-engine air tanker (SEAT) for assessment against other aerial firefighting operations (e.g., rotary-wing, fixed-wing, multi-engine, multi-crew). The fleet of AT-802 on wheels continued to grow, and in 2003 the first production Fire Boss (amphibious AT-802) was leased for a trial. In 2014, 4 additional Fire Boss aircraft were purchased for the new British Columbia contract bringing the fleet total to 14 Fire Boss and 11 AT-802 on wheels.

In the late 1990s, the amphibious SEAT was relatively new, and there was a perceived need to demonstrate the aircraft's capabilities to clients. New SOPs were developed utilizing the wheeled aircraft experience. As operational experience was gained with the Fire Boss, the pilots learned the capabilities of the aircraft through occurrences of exceeding limitations and SOPs (flying overweight, experimenting with flap settings, takeoffs below the published stall speed, etc.). As they conducted operations in more demanding conditions (such as shorter takeoff runs at more demanding lakes closer to fires), the pilots began competing with each other and refined an unorthodox procedure to “horse it off”: a manoeuvre that takes advantage of the aircraft's capability to pitch up and lift off at lower indicated airspeed and shorter distances.

At the request of customers, the company asked the manufacturer about an increase in the MTOW limit so that a greater load of suppressant could be carried, but the manufacturer did not support this idea. The original Fire Boss model was equipped with a 1350-SHP engine, and the manufacturer did develop an optional engine package, which increased the engine power to 1424 SHP. This option improved the takeoff and climb performance as the MTOW remained the same.

There were competitive advantages to the SEAT operation, provided that it could meet operational needs. The effort to compete with other aircraft types and operators and meet client requests created an environment where exceedances of the aircraft's limitations occurred.

In 2008, Conair developed STC P-LSA08-072, Issue 5, which increased the engine power to 1600 SHP. This STC improved the takeoff and climb performance to its current status; again, the MTOW remained the same.

The customers became convinced of the aircraft's value in fire management; however, practices of operating outside of the aircraft's airspeed limitations persisted among some pilots.

Conair added the Fire Boss aircraft to its firefighting operations before implementing formal risk management processes. Informal assessments of the operational flight risks associated with the use of the Fire Boss were undertaken; however, behaviours such as operating below the published stall speed (COM 3.7.1), repetitive encounters with wing-tip vortices, or not staying together as a group during ferry flights, continued to exceed the operating policies and procedures. In an effort to encourage compliance with the company's safety policy, the DFO and the CP began to use informal coaching to address the behaviour of the pilots that had evolved throughout the introduction of the Fire Boss.

By 2013, the company's AT-802A Fire Boss operation in Alberta consisted of 2 groups: 1 group had 6 aircraft and the other had 4. The DFO and CP were satisfied with how these groups were managing client expectations and the competitiveness and urgency that can develop in firefighting operations.

In 2014, the company began a multi-year contract with the government of British Columbia for SEAT aerial firefighting operations, which included 4 SEAT aircraft plus a Bird Dog aircraft. The British Columbia Fire Boss base was operated with some new and some returning contract pilots. The geographical region served by this group was mountainous, with narrow lakes at higher elevations confined by high terrain, making group scooping operations more challenging. Although this operation was new, it was viewed by management as an extension of the Alberta operation, and no additional hazard identification or risk analysis process was deemed to be necessary. An operational safety survey of the British Columbia base was conducted by the manager of quality assurance in May 2014; no risk findings were made.

1.17.3 Team performance

Management was aware that interpersonal differences with respect to how to operate the aircraft or fly the missions existed in all Fire Boss groups, and contributed to some flying the aircraft below minimum airspeed limitations. These systemic issues were discussed during base visits by the CP and DFO. These coaching discussions, combined with the assessment and selection of pilot groups, were the primary means of mitigating the issues.

Before the organizational changes that occurred in 2012, each aircraft type had a company check pilot who was responsible for maintaining company standards (e.g., compliance with policies and procedures, the safe operation of aircraft, and relief flying to cover temporary vacancies). The changes to the management structure resulted in 3 check pilot positions becoming vacant. A remedial measure was taken by assigning a senior line pilot, who was not a manager, in each group to carry out some of the base administrative and coordination duties.

The CP and the DFO routinely conducted base visits, including base safety audits; however, their operational workload increased with the vacancies in management positions, the unexpected resignation of the new DSS, and the continuation of new company expansion programs.

Following an inter-base exchange of 2 pilots, personnel issues at the British Columbia base were raised informally. The DFO and CP visited the base about 5 weeks before the accident to evaluate the effects of this change. During the visit, the DFO coached the British Columbia group about interpersonal dynamics within the group and to slow down and follow procedures. Management believed that this coaching had been effective and that these issues had been resolved. No hazard reports on this issue were identified in the safety management system (SMS), no formal documentation was created, and no further follow-up to this mitigation was undertaken to check that it had been successful.

1.17.4 Safety management

1.17.4.1 General

Safety management refers to an organization's ability to identify hazards that are associated with its operation and to put mitigations in place to reduce the risks associated with those hazards to a level that is as low as reasonably practicable.

In terms of safety, risk assessment is the process whereby

- hazards are identified,

- the risk associated with those hazards are analyzed or evaluated, and

- appropriate ways to eliminate or control the hazards are determined. Footnote 18

Effective hazard mitigation requires

- knowledge of, and competence in, the field being analyzed;

- processes to support the identification of hazards;

- means of identifying effective mitigations; and

- processes for tracking mitigations and identifying whether further action may be required.

All organizations engage in some form of safety management. In some domains, SMS provides a formalized approach to safety management; it may be required by regulation and audited periodically by a regulator or third party.

An organization that is committed to managing safety effectively is governed according to a philosophy of continual improvement, which is communicated to employees and stakeholders both explicitly, by means of values and mission statements, for example, and implicitly, through day-to-day actions. This philosophy is formalized through policies that clearly communicate the importance of safety and recognize the contribution of each person in an organization to improving safety. Consequently, policies should be enacted through procedures that are in keeping with the organization's safety philosophy and policies.

1.17.4.2 Conair's safety management system

Conair's safety management program was initiated in 1996. The company hired a full-time safety manager and concentrated on developing a culture of openness in an effort to improve the safety of flight operations. In 2008, the safety manager retired and Conair recruited a new manager of safety to continue development of the company's SMS. Conair operated under CARs Subparts 702 and 703 and was not required to incorporate a formal SMS but it voluntarily developed an SMS using TC's guidance for Subpart 705 operations. A comprehensive external (insurance related) SMS audit (covering occupational health and safety, and the rest of operations) was completed in 2014 with a very favourable audit of the company's processes.

The Conair Safety Management System Policy and Procedures Manual describes its approach to safety management as follows:

[W]e manage risk through our Health and Safety Program, policies and procedures, hiring practices, employee orientation and training, operational control and on-going communication.

[…]

As a proactive safety organization, our commitment is to effectively identify all hazards and reduce the daily operational risks to our employees, our customers and our equipment. By developing a ‘reporting culture' within all departments of our operation, we ensure that correct and timely information is being regularly assessed and acted upon to improve safety throughout the company.

[…]

Company-wide safety targets and objectives have been established.

[…]

The success of each department to improve their safety performance shall be measured. Footnote 19

Conair has implemented a Safety Management System that has 1 goal - to achieve “zero” accidents and incidents by ingraining safety as everyone's overriding responsibility! Footnote 20

In terms of SMS processes and outputs, Conair conducted a full flight test program in 2008 as part of the power-increase STC for the Fire Boss to determine the safe operating envelope with the higher takeoff power. This data resulted in the identification of hazardous stall characteristics, which were mitigated by a requirement for warning placards to be installed in the aircraft in view of the pilot. The data were not used in the STC to quantify the increased performance, and it was decided to retain the conservative performance data provided in the Wipaire airplane flight manual supplement for the aircraft with a 1350 SHP engine.

Two risk assessments were conducted prior to the departure of 2 senior managers in 2012. The risk assessments identified the hazard that important safety elements might be dropped due to increased workload. Temporary mitigations were implemented to redistribute priorities and responsibilities among other senior managers, but an effective solution had to be implemented before training started in the spring of 2013.

As a consequence of the reorganization that began in 2010, the DSS position was vacant for about 2 years. With support from other managers, the DFO retained the DSS responsibilities; the workload of these 2 positions was demanding. Encouraging the pro-active reporting of hazards was one of the safety activities that dropped off, as indicated by the lack of pro-active safety reporting in the company SMS records, although risk assessments were continued on reactive hazard reports that were viewed as potentially urgent.

Despite years of effort, employee buy-in and safety reporting required continuous encouragement. These processes were more firmly established in the Abbotsford, British Columbia, hangar maintenance operation, likely because most aircraft maintenance engineers (AME) worked all year in the same environment, whereas the pilot community worked on seasonal contracts. A large number of safety reports were initiated through flight operations feedback on equipment changes and upgrades. However, a review of the safety reporting database identified that reporting on flight operations issues (e.g., competitive flying, SOP non-compliance, wake turbulence encounters) was predominantly verbal from line pilots to the CP or DFO. Written submissions were occasionally forwarded to management, but subsequent documentation was not always completed which left no record of the rationale supporting the decisions that were made. Some corrective actions, often the more complex ones, took time to implement. SOP changes were often saved for off-season implementation and changed as a set to prevent hastily made changes in the middle of a fire season. However, in some cases, the line pilots believed that delaying implementation for even 1 week was too long of a delay.

Between 2013 and 2014, the DFO/acting DSS established a flight operations monitoring program for the AT-802A using a DAAM system. Footnote 21Monitoring identified an engine parameter exceedance due to a pilot technique issue with a group of pilots, which led to improvements in the training program. Data monitoring also resulted in risk assessments on aircraft upgrades. The focus of those assessments was more on the technical aspects of the changes and less on the flight operations aspects. Field visits and base safety audits were established for operations; however, team issues in British Columbia were not documented in these operational safety surveys. No reports about British Columbia team operations from Bird Dog pilots or customer air attack officers were made.

The DFO/acting DSS prioritized monitoring trends in the SMS database and, in 2014, identified that procedures needed to be specific, relevant, and brief to remain practical for this type of visual flight operation, where pilot judgement and stick-and-rudder skills played such a critical role in safety. A trend identified in occurrences centred on communication between pilots and lack of leadership by pilots-in-command in multi-crew operations like the CL215T operations. Between January and November 2014, approximately 70 flight operations safety reports were reviewed by the Pilot Safety Committee.

1.17.5 Safety culture

Conair employs the slogan “Target Zero—A Culture of Safety” to address safety management.

Safety culture can be defined as the shared values and beliefs that interact with an organization's structures and control systems to produce behavioural norms, and it is important to safety management. As a description of what the members of an organization collectively believe is important and valuable, safety culture is a critical determinant of how people behave on a day-to-day basis. Safety culture tacitly communicates expectations to new and existing members of an organization and, as such, impacts both the degree to which work is accomplished safely and the degree to which members of an organization comply with policies and procedures.

Conair management was actively working on developing and sustaining its safety culture through all of its SMS processes and activities; safety of operations was a constant agenda item in senior executive meetings.

1.17.6 TSB Watchlist

Safety management and oversight is a multi-modal issue on the 2014 Watchlist. The Watchlist is a list of issues posing the greatest risk to Canada's transportation system; the TSB publishes it to focus the attention of industry and regulators on the problems that need addressing today.

As this occurrence demonstrates, effectively managing safety risks poses a challenge to all air operators, especially concerning proactively identifying risks that may not be evident until after an incident occurs. Active reporting by frontline personnel is a cornerstone of proactive risk management.

The Watchlist says:

Transport Canada must implement regulations requiring all operators in the air industry to have formal safety management processes. And Transport Canada must oversee these processes.

In all transportation modes, those companies that do have a safety management system must, in turn, demonstrate that it is working—that hazards are being identified and effective risk mitigation measures are being implemented.

Finally, when companies are unable to effectively manage safety, Transport Canada must not only intervene, but do so in a manner that succeeds in changing unsafe operating practices.

1.18 Additional information

During the wreckage examination, 2 hazards were identified concerning potential control interference in the cockpit. One was exposed rudder control cables on the floor that ran along both sides of the pilot's seat. These cables may be subject to interference by items placed on top of them. The other was the exposed elevator control push-pull tube, which is attached to the control stick about 4 or 5 inches above the floor under the pilot's seat and runs parallel to the longitudinal axis of the airplane. The push-pull tube may be subject to interference by loose objects on the floor becoming lodged on its left side and preventing full left roll control input.

1.19 Useful or effective investigation techniques

Not applicable.

2.0 Analysis

2.1 General

This analysis will focus on the operational procedures, management oversight, and other underlying factors that caused or contributed to the accident. It will also discuss why previously identified risky takeoff practices were not addressed by the operator's safety management system (SMS).

2.2 Aircraft takeoff and stall performance

Several situations can disrupt the airflow over the wings of an aircraft and result in separation of the airflow from the upper wing surface, contributing to a stall event. Although the full-power-on stall characteristics of the AT-802A in the Fire Boss configuration with the 1600-shaft-horsepower (SHP) engine modification are undocumented, flight testing with partial power in the takeoff configuration demonstrated that the stall would occur at 65 knots indicated airspeed (KIAS) with a typical roll to the right. Calculations determined that T685's airspeed indicator should have been indicating 67 knots at liftoff, but the accuracy and reliability of the airspeed indicator at low airspeeds is questionable. The aircraft lifted off and rolled to the right. Because of the low altitude, the right wing tip's contact with the water surface prevented the aircraft from rolling excessively and allowed it to remain upright. This is consistent with T685 entering a wing stall moments after liftoff, which would cause a loss of control and collision with the water.

The investigation identified 2 scenarios that, separately or in combination, likely contributed to this accident: a wing stall, and/or a wing-tip vortex encounter.

Had the aircraft lifted off at a higher indicated airspeed, the first scenario could be discounted; but, given the low airspeed at liftoff and the possibility of exceeding the critical angle of attack (AOA), the first scenario must be considered a potential cause.

Reliance on power (slipstream) and pitch capability to get airborne in a single-engine aircraft below the published power-off stall speed means that the outboard sections of the wings could be in a stalled condition until the power-off stall speed is exceeded. This practice is an example of accepting avoidable risks rather than taking a few seconds to accelerate above the published power-off stall speed to minimize the risks. All pilots had received stall training at altitude, but some had not considered the risk (probability or consequences) of a stall at takeoff, in spite of the placards in the aircraft. Therefore, issues of stall dynamics at takeoff were not equally recognized or understood by all company Fire Boss pilots.

The standard operating procedures (SOPs) for the Fire Boss runway takeoff specify a target liftoff speed, whereas SOPs for the water takeoff do not. The water takeoff procedure, as prescribed in the company's SOPs, indicates that it is normal to feel a buffet at liftoff. Flight testing demonstrated that the stall warning activates at 75 KIAS and the buffet occurs at 65 KIAS, about the same time as a wing stall while some power is applied. The airspeed indicator is known to be unreliable at or near the stall speed, and the aircraft was not equipped with an AOA indicator.

These factors demonstrate that at speeds below 75 KIAS, the stall warning is the last defence, and the pilot could be at risk of suddenly losing control due to a full-power-on stall with no further warning.

As seen in this occurrence, pilots were taking advantage of engine power and pitch control capability to get the heavy aircraft airborne at relatively low speed. The operator's standard takeoff procedures did not specify a liftoff speed for scooping operations. Lifting off below the published power-off stall speed contributed to a loss of control at an altitude insufficient to permit a recovery. If takeoff procedures do not specify a liftoff speed, pilots may take advantage of engine power and pitch control capability to get airborne below the published stall speed, risking loss of control at an altitude insufficient to permit a recovery.

This takeoff practice has carried over from years past. It has likely exposed pilots many times over the estimated 100 000 completed scooping takeoffs to the risk of losing control due to power-on stalls. As no adverse consequences had previously been reported, and pilots were not able to distinguish between a stall buffet and a wing-tip vortex encounter, it is likely that these buffets were misdiagnosed and attributed to a typical wing-tip vortex encounter. In the takeoff condition in which the aircraft is heavy, its speed is below the published stall speed, and it has a high AOA, with no remaining defences, a small pitch command error could have caused the wings to exceed the critical AOA and stall completely.

In the second scenario, wing-tip vortices may have been encountered. This phenomenon is always present somewhere behind an aircraft in flight and is well known to Fire Boss pilots, who usually operate in groups. Wing-tip vortices are unpredictable, and the light and variable wind on the lake produced conditions that were ideal for vortices to linger over the water. Given T685's position behind and to the right of the lead aircraft, it is not likely that T685 encountered the lead aircraft's left wing-tip vortex. However, it is possible that T685 overtook the lead aircraft's right wing-tip vortex at, or beyond, the lead aircraft's liftoff point. T685's right-hand wing may have encountered the down-flowing side, or the left-hand wing may have encountered the up-flowing side of the counter-clockwise-rotating vortex generated by the lead aircraft's right-hand wing, resulting in a roll to the right leading, in turn, to the right-hand wingtip making contact with the water.

There were, then, factors that made the aircraft susceptible to a wing stall in undisturbed air or susceptible to encountering a wing-tip vortex generated by the lead aircraft. As a result, a wing stalled either independently or in combination with an encounter with a wing-tip vortex generated by the lead aircraft. This caused a loss of control moments after liftoff, and resulted in the right-hand wing tip contacting the water and in a subsequent water-loop.

The takeoff condition, with the aircraft heavy, its speed below the published power-off stall speed, and a high AOA, contributed to the loss of control.

2.3 Competitive behaviour and team oversight

Until some time after the increased-power supplemental type certificate (STC) (1600 SHP) was incorporated in 2008, the Fire Boss aircraft was operated in a manner that allowed the company and the pilots to learn the aircraft's capability and limitations and its value in single-engine air tanker (SEAT) firefighting operations.

Attitudes and practices within the company have evolved since then. By 2013, efforts by management to encourage compliance with company procedures, safety policies, and safety culture led management to believe that the Fire Boss bases and operations were operating in accordance with company expectations and that their efforts were achieving success. However, some of these historical behaviours and practices appeared again in the British Columbia operation in the 2014 season. These issues were not entered into the SMS records, but management learned about them informally, and became aware that differences in risk tolerance and non-compliance with procedures were creating conflicts within the group. Trying to exceed the client's expectations may have unwittingly contributed to the competitive manner in which the aircraft was flown by some individuals. Efforts by the director of flight operations (DFO) and chief pilot (CP) to address these issues began with base visits, which included coaching pilots; however, this was not a permanent mitigation strategy. Without sufficient management supervision, both the lack of specified takeoff speed in the SOP and the client influence may have contributed to the manner in which the aircraft was flown by some individuals.

2.4 Safety management

Implementing effective safety management practices is a long-term endeavour that requires consistent commitment by senior management and the allocation of adequate resources. During the early years of Fire Boss operations, procedures were written to address known unsafe conditions that had been identified through first-hand experience on the Fire Boss and other aircraft types. Conair's formal hazard identification and risk management processes were not fully developed at the time, so no documented systematic reviews of hazards and risks were undertaken. The SOPs described an operational takeoff technique that did not draw from a proactive hazard and risk analysis of the aircraft's stall performance. Using a procedure that included risk of a low-speed stall contributed to the accident.

Although training provided pilots with awareness of hazards, such as a power-on stall, neither the training, nor the placards, nor company oversight was effective at preventing pilots from operating below published minimum airspeed limitations. Despite the company's estimate that 100 000 scooping operations had been completed with the Fire Boss over the years, and the operator's intentions and efforts to proactively identify hazards and mitigate risks, the company hazard registry did not contain any entries regarding hazards during the takeoff or other phases of flight for the Fire Boss operations. Training covered the topic of wake turbulence and unofficial procedures to avoid wake turbulence encounters; however, there was no documentation of the fact that Fire Boss pilots continued to encounter wing-tip vortices multiple times per day.

The benefit of documentation is that it provides the rationale to support decisions and actions. Quality assurance and tracking processes can then be used to determine whether the changes have achieved, and will sustain, the desired outcome. The informal process led to some beneficial changes which, by 2013, led management to believe that their efforts to promote safety culture, policies, and procedures were showing signs of success. However, the fact that management remained unaware of the resurgence of unsafe practices and unsafe conditions in the British Columbia group during the 2014 fire season indicates a weakness in the process.

The most difficult safety management processes to implement were the proactive ones (i.e., reporting safety-related concerns regarding events that might occur). Pilots were committed to working under this SMS, but were not consistent in raising safety issues proactively. Encouraging proactive safety reporting was a management task that was reduced to manage the excessive workload. Without this source of information, management oversight alone was not effective in assessing the risks.

Even though an SMS and processes were in place, an understaffed management structure during organizational changes likely led to excessive workload for existing managers. Risk assessments carried out by management in 2012 had identified that the limited number of senior personnel could lead to important safety elements being dropped due to increased workload. This situation occurred, thereby requiring managers to continually prioritize workload issues. This contributed to risks, contained within the SOPs, not being addressed through the operator's SMS, resulting in continued aircraft operations below published minimum airspeed limitations. If organizations do not maintain the necessary management resources to oversee effective safety management practices, long-term efforts may dissipate, resulting in the risk of unsafe practices persisting in flight operations.

The pilot's takeoff procedure complied with company procedures, but the procedure contained elements of risk which exposed the pilot and the aircraft to the hazard of a power-on stall. The takeoff procedure had not been subjected to a formal risk assessment. Pilots new to the operation, and even pilots experienced on the aircraft type, may not have been aware of critical safety issues which can be unique to each aircraft model in a restricted classification. It is possible that pre-stall buffets due to handling errors, which were common for years, were misdiagnosed and mistakenly attributed to other causes such as wake turbulence, mechanical turbulence, or wind gusts. If the aircraft is operated outside of the demonstrated flight envelope, there is a risk that pilots will be exposed to aircraft performance for which they are not prepared.

3.0 Findings

3.1 Findings as to causes and contributing factors

- A wing stalled either independently or in combination with an encounter with a wing-tip vortex generated by the lead aircraft. This caused a loss of control moments after liftoff, and resulted in the right-hand wing tip contacting the water and in a subsequent water-loop.

- The operator's standard takeoff procedures did not specify a liftoff speed for scooping operations. Lifting off below the published power-off stall speed contributed to a loss of control at an altitude insufficient to permit a recovery.

- The takeoff condition, with the aircraft heavy, its speed below the published power-off stall speed, and a high angle-of-attack contributed to the loss of control.

- An understaffed management structure during organizational changes likely led to excessive workload for existing managers. This contributed to risks, contained within the standard operating procedures, not being addressed through the operator's safety management system, resulting in continued aircraft operations below published minimum airspeed limitations.

3.2 Findings as to risk

- If takeoff procedures do not specify a liftoff speed, pilots may take advantage of engine power and pitch control capability to get airborne below the published stall speed, risking loss of control at an altitude insufficient to permit a recovery.

- If the aircraft is operated outside of the demonstrated flight envelope, there is a risk that pilots will be exposed to aircraft performance for which they are not prepared.

- If organizations do not maintain the necessary management resources to oversee effective safety management practices, long-term efforts may dissipate, resulting in the risk of unsafe practices persisting in flight operations.

3.3 Other findings

- The exposed rudder control cables on the floor, which run along both sides of the pilot's seat, may be subject to interference by items placed on top of them.

- The exposed elevator control push-pull tube, under the pilot's seat, may be subject to interference by loose objects on the floor

4.0 Safety action

4.1 Safety action taken

Conair hired a safety manager and a company check pilot for the Fire Boss fleet before the 2015 spring training season started.

Conair has put forward a risk mitigation plan for 2015–2016, applicable to the company AT-802 fleet. The plan addresses issues mentioned in this TSB report, plus an additional issue identified in-house:

- Aileron-rudder interconnect arms were found to be incorrectly manufactured with a 0°−5° bend rather than the 11° bend specified in the Air Tractor drawing. The purpose of the bend is to hold the aileron-rudder interconnect cable away from an adjacent arm. All of these arms in the company fleet have been replaced. The manufacturer is aware of the manufacturing anomaly.

- Instances in the company fleet of elevator-flap interconnect cables wearing through a rub strip on the air conditioning air plenum were found. Company maintenance has added an annual inspection to its supplemental maintenance document with criteria to inspect this particular cable run, paying particular attention to where it has been found to rub.

- The possibility of foreign objects on the cockpit floor becoming lodged on the left side of the control stick under the elevator push-pull control tube beneath the pilot seat was analyzed for interference with left aileron control input. Conair chose to manage this risk by engineering a physical defence. Conair Engineering Order EO3753 installs a boot to surround the lower end of the cockpit control stick and yoke assembly to prevent any foreign objects from becoming lodged under the control stick. This installation has been completed fleet-wide.

- Elimination of loose items in the cockpit: Pilots are instructed to keep areas around control cables and tubes clear and free at all times. Conair has also designed additional storage space in the cockpit. Engineering Order EO3737 introduces a storage box mounting to the existing map holder. Prototypes have proven to help manage the risk; this storage solution will be implemented fleet-wide before the 2016 operating season.

- Ionode Onboard Loads Monitoring system (Latitudes Technology) will be installed on each Fire Boss for the 2016 fire season. The device will record preset parameters which can include aircraft pitch angle at takeoff, flap setting, airspeed, ground speed and more to enhance operational oversight so that unsafe techniques such as forcing the aircraft to lift off at unsafe airspeeds can be eliminated.

- Conair is endeavoring to enhance its hazard identification and risk assessment efforts to ensure all hazards associated with the Fire Boss operation are identified, assessed and mitigated. Ground school material and operational procedures are being reviewed and will be modified before the 2016 season to ensure that pilots are trained to mitigate all hazards of the operations.

This report concludes the Transportation Safety Board's investigation into this occurrence. the Board authorized the release of this report on . It was officially released on .

Appendices