Rail Recommendations R14-01, R14-02, R14-03

Table of contents

Date Issued:

23 January 2014

Forwarded to:

The Honourable Lisa Raitt, P.C., M.P.

Minister of Transport

Transport Canada

Ms. Cynthia L. Quarterman

Administrator

Pipeline and Hazardous Materials Safety Administration

Background

On 05 July 2013, at about 2250 Eastern Daylight Time, Montreal, Maine & Atlantic Railway (MMA) freight train MMA-002 (the train), en route from Montréal, Quebec, to Saint John, New Brunswick, was stopped at Nantes, Quebec (Mile 7.40 of the Sherbrooke Subdivision), the designated MMA crew change point. The train, consisting of 5 head-end locomotives, 1 VB car (special purpose caboose), 1 box car, and 72 Class 111 tank cars carrying flammable liquids (petroleum crude oil, UN 1267, Class 3), was then secured on the main track on a descending grade.

Shortly before 0100 on 06 July 2013, the unattended train started to move and gathered speed as it rolled uncontrolled down the descending grade towards the town of Lac-Mégantic, Quebec. Sixty-three (63) Class 111 tank cars and the box car derailed near the centre of the town. Most of the derailed cars released their contents due to tank car damage. The released product ignited almost immediately, resulting in a large pool fire that burned for more than a day. The petroleum crude oil that did not burn permeated and contaminated the downtown soil, with some crude oil reaching two rivers and Mégantic Lake. The 63 derailed tank cars were transporting 6.72 million litres of petroleum crude oil from the Bakken field in North Dakota. During the derailment, approximately 5.98 million litres (89%) of product was released. This derailment is among the largest on-land oil spills in North American history.

Forty-seven (47) people were fatally injured. Many buildings, vehicles, and the railway tracks were destroyed. About 2000 people were initially evacuated from the surrounding area (TSB occurrence R13D0054).

Safety Issues – Context

In recent years, the transportation of crude oil by rail has increased dramatically in North America such that the amount of crude oil that is now being shipped by rail is staggering. In Canada, shipments of crude oil by rail have increased from a mere 500 car loads in 2009 to 160 000 car loads in 2013. Footnote 1 In the United States, crude oil shipments have increased from 10 800 car loads in 2009 to about 400 000 in 2013. Footnote 2

According to the Rail Energy Transportation Advisory Committee and data from the North American Freight Car Market, longer-term projections for crude oil and its shipment by rail include:

- The United States could produce as much as 11.6 million barrels per day (b/d) of crude by 2022.

- The Canadian production is expected to reach as much as 5.6 million b/d of crude by 2025.

- In North America, roughly 1.0 million b/d of crude is currently moved by rail and the total volume of crude transported by rail is expected to grow to 4.5 million b/d in the next 10 years.

Given this significant projected growth, the TSB is concerned that infrastructure and operating conditions may not ensure a safe rail system now and in the future. With the introduction of unit trains, Footnote 3 which can consist of 80 tank cars or more carrying large volumes of liquid hydrocarbons over long distances and through urban areas, the risks to the public and the environment along the train’s route have increased significantly.

Efforts are ongoing to reduce the risk of accidents involving trains carrying dangerous goods and to reduce the consequences to the public and the environment from derailments. Over the years, these efforts have focused on restricting the products carried, improving the crashworthiness of tank cars transporting dangerous goods, and adopting operational measures to minimize the frequency and consequences of derailments involving dangerous goods.

As part of its ongoing investigation into the Lac-Mégantic accident, the TSB has identified three key safety issues that must be addressed to further improve the safety of the Canadian rail system:

- vulnerability of Class 111 tank cars to sustain damage,

- route planning and analysis for trains carrying dangerous goods, and

- requirements for emergency response assistance plans.

Vulnerability of Class 111 tank cars to sustain damage (R14-01)

There are approximately 228 000 Class 111 tank cars currently in service in North America. These cars carry many types of dangerous goods, mainly Class 3 (flammable liquids) and Class 8 (corrosives). The majority of these tank cars are general-service cars such as DOT-111A100W1.

Many Class 111 tank cars do not have top fitting protection, head shields or thermal protection, and are not jacketed. The sides and heads of these tank cars are typically constructed with 7/16-inch-thick steel plate, which is thinner than some other classes of tank cars. When involved in accidents, these Class 111 tank cars are vulnerable to head and shell damage due to impacts, as well as fitting damage, which can result in the release of product. Furthermore, without thermal protection, additional product can be released through excessive venting of the safety relief device(s), or worse, through a thermal tear, which can result in complete product loss.

Photo 1. Vulnerability of general-service Class 111 tanks cars to sustain damage during a railway accident

Previous recommendations

The TSB has been commenting on the vulnerability of Class 111 cars for about 20 years. In previous investigations, the TSB identified the risks posed by the release of product from Class 111 tank cars and the vulnerability of these cars to release product due to accident damage. The weaknesses of Class 111 tank cars have been acknowledged by the regulator and industry. Some of the TSB safety messages on Class 111 tank cars are listed in Appendix A.

As a result of an accident involving a petroleum product unit train near Lévis, Quebec, in August 2004, the Board recommended that:

The Department of Transport extend the safety provisions of the construction standards applicable to 286 000-pound cars to all new non-pressurized tank cars carrying dangerous goods.

Subsequent to this recommendation, an Association of American Railroads (AAR) task force examined improvements to tank car safety, and the AAR tank car standards were amended to incorporate a number of enhancements to all new Class 111 tank cars built for the transportation of crude oil and ethanol in Packing Group (PG) I or PG II. These enhancements include: construction of the tank cars to 286 000-pound standards; protection of the service equipment on the top shell; use of reclosing pressure relief devices; use of normalized steel for the tanks and heads; increased minimum thickness for all tank cars not jacketed and insulated; and at least ½-inch half-head shields. The AAR petitioned the Canadian and United States regulators in 2011 to adopt these changes in their respective regulations. After reviewing the AAR petition, Transport Canada (TC) discussed these modifications during a consultative meeting with stakeholders in February 2013, and proposed them for adoption in the Transportation of Dangerous Goods Regulations in Canada Gazette, Part I, in January 2014. TC's response to this recommendation was assessed as Satisfactory Intent.

However, recent accidents at Cherry Valley, Illinois (June 2009), Lac-Mégantic, Quebec (July 2013), Aliceville, Alabama (November 2013), Casselton, North Dakota (December 2013), and Plaster Rock, New Brunswick (January 2014), again highlight the vulnerability of these cars to accident damage and product release. Following the Cherry Valley investigation, the United States National Transportation Safety Board (NTSB) recommended that the Pipeline and Hazardous Materials Safety Administration (PHMSA):

Require that all newly manufactured and existing general service cars authorized for the transportation of denatured fuel ethanol and crude oil in Packing Groups I and II have enhanced tank head and shell puncture-resistance systems and top fittings protection that exceeds existing design requirements for DOT-111 tank cars (NTSB; R-12-5).

Lac-Mégantic – Examination of Class 111 tank cars

The examination of the 63 general-service Class 111 tank cars that derailed at Lac-Mégantic revealed that 60 of the cars (95%) had released product due to tank car damage. The following types of tank car damage were observed:

| Shell punctures: | 33 cars |

|---|---|

| Head punctures: | 26 cars |

| Top fittings: | 20 cars |

| Pressure relief devices: | 20 cars |

| Bottom outlet valves (operating lever handle): | 7 cars |

| Thermal tears: | 4 cars |

| Manways: | 2 cars |

Tank car shells and heads

Of the 63 derailed cars, the majority were impact-damaged. More than half of the cars released product due to damage to the shell (33 cars) and/or to the head (26 cars). These parts of the car structure are often subjected to impacts during a derailment. For the Lac-Mégantic tank cars, the impact damage ranged from small punctures (that is, a few inches in diameter) to large ruptures (approximately the size of the tank diameter).

The derailed tank cars were subjected to a range of impact speed and forces, depending on their position in the train. However, it is important to note that the cars at the rear of the train were travelling at much slower speeds before coming to rest, but still experienced significant tank shell and head damage as well as product loss. Some of the product release, especially from the tank cars closer to the end of the train, could have

been reduced had the tank car shells and heads been more impact-resistant. Specifically, tank cars built with thicker steel, full-head shields, and tank jackets would have been better protected.

Bottom outlet valves

Of the 63 derailed cars, 7 cars exhibited impact damage resulting in an open or partially open bottom outlet valve (BOV), allowing the release of product. For each, the operating lever handle for the BOV had been damaged. This issue was highlighted during the investigation into a 2013 derailment involving Class 111 tank cars in Ontario (TSB occurrence R13T0060). TSB Rail Safety Advisory (RSA) 15/13 was issued to TC Footnote 4 to communicate the risk of product loss through BOV handles that are damaged during derailments.

Top fittings

Approximately half of the derailed tank cars were equipped with top fitting discontinuity protection that met the requirements specified by the AAR for cars ordered after October 2011. Only 18% of these tank cars released product due to damage. For the tank cars with top fittings that were not so protected, 66% experienced product loss due to damage. The majority of the tank cars with damaged top fittings came to rest on their sides or upside down, allowing the product to flow from the damaged top fittings to feed the pool fire. Top fitting discontinuity protection provides an effective means to reduce product release during derailments.

Pressure relief devices

Pressure relief devices (PRD) are used to reduce the build-up of excessive internal pressure. For the Lac-Mégantic tank cars, there was a significant improvement in PRD survivability when they were protected similarly to the top fittings within a protective housing. In fact, about half of the PRDs were protected and only 10% of these exhibited release of product from impact damage. For the unprotected PRDs, 29% exhibited impact damage resulting in product release. The protective housing around the PRD provides an effective means to reduce product loss during accidents.

Fire survivability

Of the 63 derailed cars, 4 cars exhibited thermal tears. At least 2 occurred within 20 minutes of the accident. Simulations for tank car survivability have been conducted by the AAR. The simulations showed that some of the high-energy events could have been due to damaged PRDs or structural damage to the tanks. The simulations also showed that thermal protection, thicker steel, and jacketed tanks can significantly extend the time a tank car can survive in a pool fire. For example, tank cars equipped with a thermal protection system and an 11-gauge jacket exhibited fire survivability of up to 1000 minutes. For tank cars equipped with PRDs with a start-to-discharge pressure of no more than 75 psi and with high flow capacity (27 000 standard cubic feet per minute or more), the risk of tank cars building up excessive internal pressure during a fire was reduced.

In 2011, the AAR proposed upgraded standards for new tank cars built to transport crude oil and ethanol meeting the requirements of PG I and PG II. In November 2013, both the AAR and the American Short Line and Regional Railroad Association (ASLRRA) expressed support for even more stringent standards for tank cars used to transport these materials. Furthermore, the AAR and the ASLRRA suggested additional improvements for tank cars transporting flammable liquids (including PG III flammable liquids), retrofitting existing tank cars in flammable liquid service, and an aggressive phase-out of tank cars that cannot meet retrofit requirements. The suggested tank car improvements include modifications such as:

- Puncture-resistant jackets

- Full-height head shields

- Thermal protection blanket or coatings in conjunction with jackets

- High-capacity PRDs

- Reconfiguration of the BOV handles

- Possible designation of a new tank car class

Following the Lac-Mégantic accident, federal regulators in the United States and Canada are accelerating their review and consideration of enhancements to these tank cars. The Board also recognizes that many tank car owners are voluntarily building new tank cars for crude oil service that meet the AAR upgraded standards introduced for tank cars transporting PG I and PG II goods.

However, considering the susceptibility of Class 111 general-service tank cars to product release during accidents, the large number of general-service Class 111 cars remaining in service, and the increased movements of large volumes of flammable liquids by rail through many Canadian and American communities, the Board believes that further action is required immediately.

Design improvements to these types of cars are needed to mitigate the risks of a dangerous goods release and the consequences as occurred in the Lac-Mégantic accident. These should include defences such as stronger tank shells, tank car jackets, full-height head shields, thermal protection and high-capacity PRDs. Given the magnitude of the risks and given that tank car standards must be set for the North American rail industry, the Board recommends that:

The Department of Transport and the Pipeline and Hazardous Materials Safety Administration require that all Class 111 tank cars used to transport flammable liquids meet enhanced protection standards that significantly reduce the risk of product loss when these cars are involved in accidents.

R14-01

Route planning and analysis for trains carrying dangerous goods (R14-02)

The Lac-Mégantic derailment and other recent rail accidents demonstrate that, when accidents involving unit trains (or blocks of tank cars) transporting large volumes of flammable materials occur, there is significant risk for loss of life and damage to communities and the environment.

The Lac-Mégantic investigation has identified these issues relating to the operation of trains transporting dangerous goods:

- Securement of unattended trains

- Trains secured on a descending grade

- Rail conditions

- Trains left unattended and accessible for extended periods of time

- Effect of speed on the severity of the derailment

In July 2013, the TSB issued two safety advisories on the securement of trains (RSA 08/13 and RSA 09/13). Further attention is required to address the remaining issues in order to reduce the frequency of derailments and their severity. To this end, the industry has charged the AAR Tank Car Operations Working Group with evaluating alternative operational options. Some of the operational options include speed reduction, rail integrity, braking systems and emergency response. These options should be considered as part of a comprehensive strategy to identify and reduce the safety risks along the entire route used by trains carrying dangerous goods.

Relation between speed, rail breaks and derailments

The severity and consequences of a derailment are related to speed because the energy dissipated during a derailment depends on the kinetic energy of the train in movement, thus its speed and mass. Analysis conducted on Federal Railroad Administration (FRA) data Footnote 5 for main-line freight train derailments over the period from 1992 to 2001 shows that the number of cars derailed, an indicator of accident severity, is highly correlated with speed (see Appendix B, Figure 1) and with dangerous goods being released. TSB data on main-track derailments from 2003 to 2012 also indicate that higher derailment speeds are significantly associated with a higher number of derailed cars. Interestingly, FRA data from 1997 to 2001 indicate that the rate of accidents (main-line derailments per million train-miles) is higher on short lines than on major railways despite a slower operating speed. Footnote 6

FRA accident data segregated by cause show that broken rail is the factor most likely to pose the greatest risk to train operations because accidents due to broken rails are more frequent and more severe than average (see Appendix B, Figure 2). Broken rails were the cause of major derailments involving dangerous goods both in the United States (New Brighton and Arcadia) and in Canada (Mont-Saint-Hilaire [TSB report R99H0010] and Wabamun [TSB report R05E0059]). Consequently, a reduction in broken rails is essential to any strategy to improve the safety of dangerous goods transportation by rail.

Speed reduction has the potential to reduce the severity and consequences of derailments but would not necessarily result in a reduction of the number of derailments on lower classes of track due to the fact that track maintenance standards are less stringent for lower classes of track. Unless the track is maintained at a level higher than Class 2, the full benefits of speed reduction of “key trains” will not materialize.

Route planning and Circular OT-55

Route planning and analysis involves a comprehensive system-wide review of all operational changes, infrastructure modifications, traffic adjustments, and other changes affecting the safety of train movements. Safety assessments of potential routes used for the transportation of dangerous goods will help ensure that the route selected is the one presenting the fewest overall safety risks. Factors to be considered include hazards related to the nature of the product, the volume being transported, the handling of the product, speed of train operations, passenger traffic along the route (that is, shared track), railway infrastructure characteristics (for example, signaling, track class, crossings, wayside systems, traffic density), geography, environmentally sensitive areas, population density along the route, and emergency response capability along the route. In the absence of alternative routes, an assessment of the safety risks along the route is critical to enhancing rail transportation safety as the identified vulnerabilities can be proactively addressed.

Additional safety benefits can be achieved when route planning and analysis is complemented by tighter operating measures. These measures can include a maximum allowable speed for trains carrying dangerous goods and a minimum level for class of track. Although speed reduction reduces the capacity of the route, the impacts can be minimized if the speed reduction is applied selectively to the trains that present the higher risks. This practice has been in place for over 20 years in the United States for some specific dangerous goods. Based on recommendations of the Inter-Industry Task Force on the Safe Transportation of Hazardous Materials by Rail, in January 1990, the AAR issued Circular OT-55, Recommended Railroad Operating Practices for Transportation of Hazardous Materials. Circular OT-55 gave the rail industry routing guidance for selected dangerous goods, including poisonous by inhalation (PIH) or toxic by inhalation (TIH) products and radioactive materials. It defined a list of TIH products (over 200, including chlorine and anhydrous ammonia). Furthermore, it identified technical and handling requirements for “key trains” and “key routes.” Following the Lac-Mégantic accident, the definition of a “key train” was expanded in Circular OT-55-N (see Appendix C).

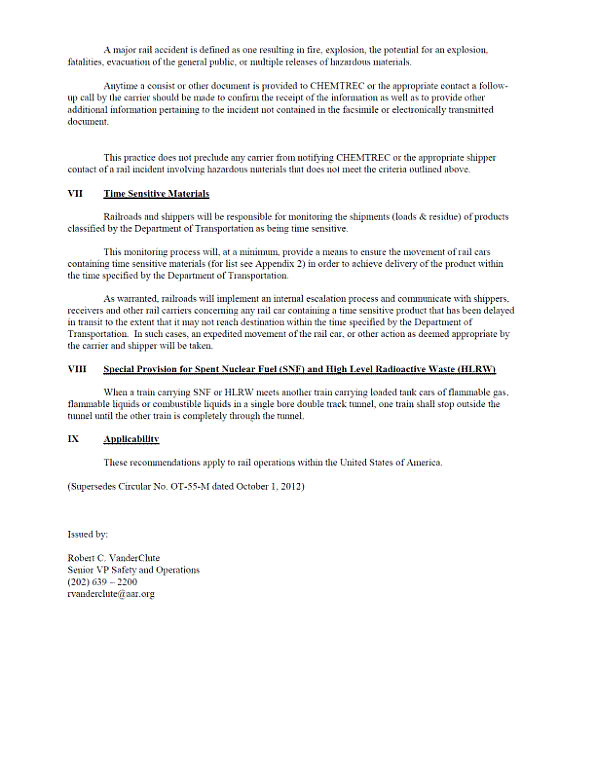

The essential elements of Circular OT-55-N are:

A “key train” is any train containing one or more cars of PIH or TIH material, anhydrous ammonia, ammonia solutions, spent nuclear fuel or high-level radioactive waste, or 20 car loads or intermodal portable tank loads of any combination of other hazardous materials.

Key trains are limited to a maximum speed of 50 mph and consist of cars that must meet certain technical standards.

In the event that a wayside device detects an abnormal condition in a key train, further speed restrictions and car handling requirements are imposed.

A “key route” is any route that carries more than 10 000 car loads or intermodal portable tank loads of hazardous materials, or a combination of 4000 car loads of PIH or TIH material, anhydrous ammonia, flammable gas, Class 1.1 or 1.2 explosives, environmentally sensitive chemicals, spent nuclear fuel, and high-level radioactive waste over a period of one year.

Track on key routes must be rated Class 2 or higher.

Key routes must have wayside defective bearing sensors spaced not more than 40 miles apart.

On key routes, all main tracks must be inspected at least twice per year and all sidings at least once per year using rail flaw detection and geometry cars. All tracks must have periodic track inspections between rail defect and geometry car inspections to detect cracks and breaks in rail joint bars.

AAR member railroads are responsible for tracking the location of PIH or TIH shipments from shipper to consignee, and ensuring the timely delivery of the material in accordance with United States Department of Transportation guidelines. They are also required to provide, on request, a list of the top 25 hazardous materials that are transported through the jurisdiction.

The requirement for a “key route” to have main tracks inspected at least twice per year and all sidings at least once per year using rail flaw detection and geometry cars would have a positive impact. It would mitigate risks associated with wide gauge and rail breaks, which are the major causes for derailments. This in turn would reduce the risk of damage to Class 111 tank cars and the release of dangerous goods.

A primary safety concern related to the transportation of dangerous goods by rail is the prevention of a catastrophic release or explosion in a densely populated area or in an environmentally sensitive area. The Lac-Mégantic accident has heightened the public’s awareness of the risks associated with the transportation of dangerous goods. Canadian municipalities are now demanding better communications about dangerous goods travelling through their territory.

Circular OT-55-N or similar operating restrictions are necessary to alleviate many of the shortcomings identified during the Lac-Mégantic investigation and other investigations involving the release of dangerous goods. However, these measures need to be complemented by a more comprehensive, proactive approach. Although Circular OT-55-N is not applicable in Canada, in October 2013, Canadian National (CN) indicated that these measures have been extended to its Canadian operations. An approach based on Circular OT-55-N, strengthened with a requirement to conduct route planning and analysis, would be a positive step to improve the safety of transporting dangerous goods by rail. Therefore, the Board recommends that:

The Department of Transport set stringent criteria for the operation of trains carrying dangerous goods, and require railway companies to conduct route planning and analysis as well as perform periodic risk assessments to ensure that risk control measures work.

R14-02

Requirements for emergency response assistance plans (R14-03)

An Emergency Response Assistance Plan (ERAP) is required by the Transportation of Dangerous Goods Regulations for certain goods that pose a higher-than-average risk when transported in certain quantities. When there is an accident, the handling of these dangerous goods requires special expertise, resources, supplies and equipment. An approved ERAP will describe the specialized response capabilities, equipment and procedures that will be available to local emergency responders and will assist emergency responders in addressing the consequences of the accident.

The risks posed by specific dangerous goods are determined based on the properties, characteristics and quantities of the dangerous goods being transported. Importers, as well as persons who offer for transport a dangerous good that requires an ERAP, must have an ERAP approved by TC.

Previous recommendation

Following the TSB investigation into the 1999 derailment, collision and subsequent fire of a CN unit train carrying flammable liquid hydrocarbons in tank cars near Mont-Saint-Hilaire, Quebec (TSB report R99H0010), the Board determined that a comprehensive emergency response plan, where roles, resources and priorities for emergency response are defined ahead of time, would enhance the emergency response and alleviate post-accident risks. The Board recommended that:

Transport Canada review the provisions of Schedule I and the requirements for emergency response plans to ensure that the transportation of liquid hydrocarbons is consistent with the risks posed to the public.

(R02-03, issued June 2002)

The Transportation of Dangerous Goods Regulations were amended to require an approved ERAP for 3 flammable liquids (UN 1202, diesel fuel; UN 1203, gasoline; and UN 1863, aviation fuel) when offered for transport or imported in a specific configuration of 17 or more interconnected rail tank cars that are each at least 70% full.

As part of its assessment of Recommendation R02-03, the Board noted that the updated ERAP application criteria, as implemented by TC, did mitigate the risks to the public posed by the transportation of large volumes of liquid hydrocarbons that were, at that time, regularly transported between Québec and Montréal in interconnected tank cars. The Board therefore assessed Recommendation R02-03 as Fully Satisfactory in August 2008.

Emergency response assistance plans

In the Lac-Mégantic accident, following confirmation that the dangerous goods involved in the fire consisted of petroleum crude oil, the emergency responders assessed the situation and estimated that approximately 33 000 litres of foam concentrate would be required to allow a continuous uninterrupted production of foam to be applied to the fire. As that quantity of supply was not available locally, the Lac-Mégantic Fire Department arranged to transport the foam concentrate from a refinery in Lévis, Quebec, about 180 km away.

In this accident, the relative proximity of the refinery, the availability of the required type and quantity of foam concentrate and the capability to deliver it to Lac-Mégantic in a timely manner provided the firefighters with one of the critical materials to successfully fight the large hydrocarbon fire. However, if this accident had occurred in a community in Canada where supplies and other specialized resources were not available in a timely manner, the emergency response efforts would have been jeopardized.

The transportation of large volumes of flammable liquids, such as petroleum crude oil, does not currently require an ERAP. However, approved ERAPs would consistently ensure that first responders have access, in a timely manner, to the required resources and assistance in the event of an accident involving significant quantities of flammable hydrocarbons.

In November 2013, an Emergency Response Working Group (Working Group) was established by the Transportation of Dangerous Goods General Policy Advisory Council. The Working Group is chaired by the Canadian Association of Fire Chiefs and is tasked to examine the possibility of extending the ERAP program to include flammable liquids such as crude oil or to recommend other viable emergency response solutions to accomplish a similar goal of ensuring access to appropriate response capability and specialized supplies. The Working Group’s recommendations are expected to address short-term or longer-term solutions or actions that TC can take to enhance emergency response.

The Board acknowledges this TC initiative. Given the significant increase in the quantities of crude oil being transported by rail in Canada, and the potential for a large spill with the risks it would pose to the public and the environment, the Board recommends that, at a minimum:

The Department of Transport require emergency response assistance plans for the transportation of large volumes of liquid hydrocarbons.

R14-03

Next steps – Lac-Mégantic investigation

The TSB investigation into the Lac-Mégantic derailment is ongoing. Further analysis of the information collected continues and more work needs to be done before a final report is published. However, as the investigation proceeds, should the Board identify additional safety deficiencies in need of urgent attention, it will make further rail safety recommendations.

Wendy A. Tadros

Chair

Transportation Safety Board of Canada

cc :

Mr. Michael Bourque

President and Chief Executive Officer

Railway Association of Canada

Mr. Joseph C. Szabo

Administrator

Federal Railroad Administration

The Honorable Deborah A.P. Hersman

Chairman

National Transportation Safety Board

Mr. Edward R. Hamberger

President and Chief Executive Officer

Association of American Railroads

Appendices

Appendix A - TSB Investigations and Safety Messages on Class 111 Tank Cars (1992 to Present)

| Report Number | Occurrence Date | Location | Summary | Safety Message | Response or Action Taken |

|---|---|---|---|---|---|

| R10T0020 | 2010-02-09 | MacMillan Yard, Toronto, Ontario | During switching operations, tank car ACFX 73936 (DOT-111A100W5) on a Canadian National (CN) yard assignment failed catastrophically and derailed. The tank car broke into 2 sections, and released its entire load of approximately 57 000 litres of ferric sulphate (UN 3264) along the roadway and adjacent tracks. A total of 2 cars derailed and 3 additional cars were damaged. There were no injuries. |

Rail Safety Advisory (RSA) 05/11 on the application of re-pads to non-pressure, non-jacketed tank cars constructed prior to September 1990. RSA 06/11 on applicable standards for non-pressure tank cars and fracture toughness criteria for material used in their construction. RSA 07/11 on suitability of existing visual method for inspecting welds that secure partial stub sill re-pads to non-pressure tanks. |

|

| R04Q0040 | 2004-08-17 | Saint-Henri-de-Lévis, Quebec | A CN petroleum product unit train derailed 18 tank cars. Approximately 200 000 litres of gasoline (UN 1203) and diesel fuel (UN 1202) spilled into the marshy area from 3 DOT-111A100W1 tank cars, but the spilled product was recovered. There were no injuries. |

RECOMMENDATION The Board believes that further attention is required to address the issue of puncture resistance of cars of lower weight and recommends that: The Department of Transport extend the safety provisions of the construction standards applicable to 286 000-pound cars to all new non-pressurized tank cars carrying dangerous goods. |

|

| R00T0067 | 2000-03-14 | Temagami, Ontario | An Ontario Northland Railway (ONR) freight train derailed 29 cars; 25 of these were tank cars containing sulphuric acid (UN 1830). Approximately 386 000 litres of sulphuric acid was spilled from 12 DOT-111A100W2 tank cars. There was minimal mortality to organisms and fish in Martin Creek and Hornet Lake. There were no injuries. |

The TSB investigation revealed that the failure of the top fitting on Class 111 tank cars caused sulphuric acid to leak, resulting in environmental impact. The TSB also found that the absence of a standard requiring that Class 111 tank cars used in the transportation of sulphuric acid be equipped with top fitting protection designed to minimize loss of product during rollover presents a continuing risk to the public and the environment. |

|

| R99D0159 | 1999-08-27 | Cornwall, Ontario | During switching operations, 6 tank cars from a CN yard assignment ran away. The cars struck the stop block at the end of the track. STEX 20520, a Class 111A tank car, derailed and its tank was punctured. Approximately 5000 gallons of a class 3 combustible liquid (NA 1993) was released but was almost all recovered. There were no injuries. |

In its investigation, the TSB concluded that, in general, Class 111A tank cars do not have sufficient protection against punctures, even in a low-speed impact due to the thinness of the tank shell and the absence of a head shield. |

|

| R95D0016 | 1995-01-21 | Gouin, Quebec (Petit lac Masketsi) | A CN train derailed 28 loaded cars of sulphuric acid (UN 1830). Approximately 230 000 litres of sulphuric acid was released from 11 DOT/CTC-111A tank cars, causing environmental damage. There were no injuries. |

The TSB found that the tank cars that lost product were all Class 111A cars, a class known to be susceptible to product loss at derailment. |

|

| R94C0137 | 1994-10-17 | Lethbridge, Alberta | A Canadian Pacific Railway (CPR) train derailed 6 tank cars containing methanol (UN 1230); 4 DOT/CTC-111A tank cars lost product and approximately 230 700 litres of methanol was released. A 20-square block area of the city was evacuated and secured by police until the spilled and remaining methanol was removed from the site. There were no injuries as a result of the accident or the product spill. |

RECOMMENDATION The risks could be mitigated by reducing the probability of product release through design improvements for protecting the cars, especially the top fittings, and/or by reducing the consequences of accidents by further limiting the types of products that can be carried in minimum specification Class 111A tank cars. The Board recommends that: The Department of Transport take immediate action to further reduce the potential for the accidental release of the most toxic and volatile dangerous goods transported in Class 111A tank cars—for example, require design changes to improve tank car integrity in crashes or further restrict the products that can be carried in them. |

|

| R94T0029 | 1994-01-30 | Near Westree, Ontario | A CN train derailed 23 freight cars as the train passed through a curve. Three Class 111A tank cars containing dangerous goods (2 cars containing vinyl acetate [UN 1301] and 1 car containing methanol [UN 1230]) released product. There were no injuries. |

The TSB investigation revealed that, even though the susceptibility of Class 111A tank cars to release product at derailment and impact is well documented, the transportation of a variety of the most hazardous products in such cars continues. |

|

| R94D0033 | 1994-01-27 | Montréal, Quebec | During switching operations, a CN yard crew detected a strong odour of gasoline. The train crew determined that PROX 47917, a CTC-111A tank car loaded with gasoline (UN 1203), was leaking from a crack in the tank shell at the “B” end of the car. The tank shell fractured as a result of being subjected to impact forces that were higher than the anticipated limits of the car design. An estimated 1125 litres (250 gallons) of product leaked from the car. |

RECOMMENDATIONS To further reduce the risk of a stub sill structural failure or sill cracks propagating into the tank shell on tank cars carrying dangerous goods, the Board recommends that:

Given that stub sill tank cars are interchanged extensively between United States and Canadian railways, the Board recommends that:

|

|

| R92W0300 | 1992-12-18 | Oakville, Manitoba | A CN train derailed 3 diesel locomotives and 29 cars; 24 of the derailed cars were tank cars transporting dangerous goods and 5 DOT/CTC-111A tank cars were ruptured. A total of 345 tonnes of product was spilled from these 5 cars (vinyl acetate [UN 1301] from 1 car, acetic anhydride [UN 1715] from 1 car, sodium hydroxide [UN 1823] from 1 car and sulphuric acid [UN 1830] from 2 cars). A total of 410 residents were evacuated. There were no injuries. |

In its investigation, the TSB revealed that the regulated products escaped only from Class 111A tank cars. These cars have a high incidence of failure when involved in accidents, and frequently transport highly flammable, toxic and environmentally dangerous materials even though better protected cars are available. |

|

| R92D0065 | 1992-04-30 | Montréal, Quebec | During humping operations, tank cars containing sulphuric acid (UN 1830) rolled free and struck 33 stationary tank cars. PROX 60066, a CTC-111A tank car, was punctured, releasing 2360 gallons of product. There were no injuries. |

The TSB found that experience has revealed that, due to their construction, Class 111A tank cars have a reduced ability to maintain tank integrity, and reduced ability to provide a degree of protection against loss of product, when compared to the Class 112 and 114 cars. |

|

| R92C0021 | 1992-03-17 | Calgary, Alberta | NATX 13950, a DOT-111A100W3 tank car loaded with molten sulphur (UN 2448), caught fire around the safety relief vent on top of the car. The fire extinguished itself before the fire department arrived. There were no injuries. |

SAFETY CONCERN The Board is concerned that undetected corrosion in molten sulphur tank cars may continue to create sulphur fires or other safety-related operating problems. Additionally, the Board is concerned that many cars in service may not meet the minimum tank shell plate thickness requirement of 7/16 inch. |

Appendix B - Severity of Derailments

Figure 1. Correlation between speed and derailed cars (source: Analysis of Railroad Derailment Factors Affecting Hazardous Material Transportation Risk, op. cit.)

Click image to enlarge.

Figure 2. Frequency and severity of freight train derailments by cause (source: Association of American Railroads)

Click image to enlarge.