Rail Transportation Safety Investigation Report R18D0067

Main-track derailment

Canadian Pacific Railway

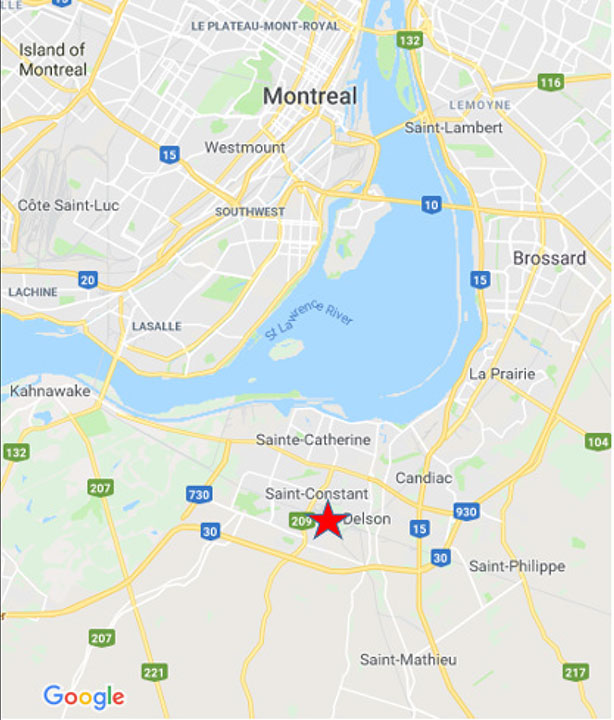

Mile 35.83, Adirondack Subdivision

Delson, Quebec

The Transportation Safety Board of Canada (TSB) investigated this occurrence for the purpose of advancing transportation safety. It is not the function of the Board to assign fault or determine civil or criminal liability. This report is not created for use in the context of legal, disciplinary or other proceedings. See Ownership and use of content.

The occurrence

On 09 July 2018, at 2100,Footnote 1 a Canadian Pacific Railway (CP) switching crew (the crew) was assigned to train FS92-09 at Delson Station, in Delson, Quebec. The crew consisted of a locomotive engineer (LE), a conductor, a brakeman and a trainee undergoing on-the-job training. All of the crew members were qualified for their respective positions, met fitness and rest standards and, except for the trainee, were familiar with the territory. The train consisted of 2 locomotives, 38 loaded cars, and 2 empty cars. It weighed about 5000 tons and was approximately 2200 feet long.

At approximately 2352, the train was exiting the CC Long SidingFootnote 2 track and travelling north at 10 mph on CP's Adirondack Subdivision (Figure 1).

The conductor, who was on the ground to handle a switch, observed sparks coming from the wheels of one of the cars. The conductor then radioed the LE to instruct him to stop the train. The LE applied the emergency brakes and made an emergency broadcast. Once the train came to a stop, the crew noted that an 81-foot-long flat car loaded with lumber (Car 25) and 4 gondola cars transporting steel coils (cars 26 to 29) had derailed (Figure 2). The conductor was trapped under the cover of one of the derailed gondola cars.

The LE then contacted the rail traffic controller (RTC) to inform him of the derailment and request assistance from emergency services. The conductor was taken to the local hospital for examination and treatment, and was discharged that same day. The consequences of the derailment were minimized by the fact that the conductor was positioned to observe the incoming movement and that he communicated with the LE in a timely manner.

At the time of the derailment, the temperature was 25 °C and the sky was clear.

Subdivision and track information

The Adirondack Subdivision extends from St-Jean Station, Quebec, Mile 20.0, to Outremont Station, Quebec, Mile 49.1. Train movements are governed by the occupancy control system (OCS), except between Mile 33.0 and Mile 49.1, where they are governed by the centralized traffic control (CTC) system. All movements are supervised by a CP RTC located in Calgary, Alberta, in accordance with the Canadian Rail Operating Rules. Rail traffic consists of approximately 6 freight trains and 18 commuter trains per day, for an annual tonnage of about 1.8 million gross tons.

Between the Delson and South Jct stations, the track is Class 3 double main track according to the Transport Canada–approved Rules Respecting Track Safety, also known as the Track Safety Rules (TSR). The maximum allowable speed in this area is 40 mph for freight trains.

The CC Long Siding track is a Class 1 non-main track measuring about 4000 feet in length. The maximum allowable speed for freight trains on this track is 10 mph. This track serves as a storage track for movements between Saint-Luc Yard and Delson Station. It is generally straight and level.

The track in the derailment area consisted of 100-pound, bolted rail manufactured between 1921 and 1931 using the Martin process.Footnote 3 The rail was laid on 10-inch, single-shouldered tie plates and on 14-inch, double-shouldered tie plates, fastened with 3 spikes per tie plate and anchored at every tie. The ties were hardwood ties and were in average condition. There were approximately 60 ties per 100 feet of track. Several gauge rodsFootnote 4 were present on this track. The ballast was made up of crushed rock. The shoulders exceeded the tie ends by approximately 12 inches.

Site examination

During the site examination, it was determined that:

- The lead locomotive had stopped near Mile 36.19, to the north of the Saint-Pierre Street public level crossing, blocking it for several hours.

- The east rail had partially rolled over and ruptured at Mile 35.83, a few inches before a compromised splice bar (Figure 3). The rail was of the head-free rail type.Footnote 5

- The first derailed car was the 25th car (SOO 601427) from the head end of the train. This car remained coupled to the head of the train, and its rear section was found on the east side and came to rest on top of the girder of the railway bridgeFootnote 6 spanning the Saint-Pierre River. Its rear truck separated from the car when the car struck the end of the bridge, resulting in damage to the bridge's southeast corner.

- The next 3 cars (the 26th to the 28th cars) derailed, but remained coupled together. They had rolled over into the ditch on the east side of the track. The last derailed car (the 29th car) came to rest upright, between the rails.

- Examination of the derailed cars did not identify any pre-derailment mechanical defects.

- A section of approximately 300 feet of track was damaged or destroyed, including the north turnout of the CC Long Siding track (Figure 4).

The east rail of the CC Long Siding track had shifted outwards, and several spikes were lifted on the inside of the rail. Numerous marks were present along the rail base. The CC Long Siding track infrastructure showed no wheel marks to the south of the derailed cars. The ties in the curve at the north end of the CC Long Siding track leading to the main track were destroyed. Several of the ties were shattered, with the wood fibres on the top surface shredded by the wheels. Deep grooves were visible on other parts of the ties, and the wood was deteriorated on many of the ties.

Based on the tie condition and the damage at the occurrence site, the ties were unable to withstand the lateral forces exerted by the rolling stock when the train negotiated the turnout curve. A section of the outside rail rolled over when the 25th car went through, resulting in its derailment and the sudden rupture of the east rail. Unable to withstand the weight of the derailed rolling stock, the ties delaminated, causing the derailment of the other cars and the destruction of the infrastructure.

CC Long Siding track inspections

The TSR establish minimum requirements for the frequency and methods of track inspections, according to class of track and annual tonnage. Only a monthly visual inspection is required for a Class 1 track with an annual tonnage of less than 5 million gross tons. This inspection must be conducted by an inspector on foot or on board a track vehicle at a speed that enables that inspector to make the required visual inspections and to detect any non-compliance with the TSR. Both turnouts leading to the Class 3 main track must be inspected visually on a weekly basis. Furthermore, an inspection on foot must be performed monthly to assess the general condition of turnouts leading to Class 3 main tracks.

The most recent visual inspection of the CC Long Siding track and the 2 turnouts leading to the main track had been conducted on 29 June 2018. No defects were noted.

The rail flaw inspection, which consists of testing for internal rail defects, is not mandatory for Class 1 track. However, internal rail defect testing on part of the CC Long Siding track had been performed on 14 April 2015. This inspection identified 3 rail defects: a vertical split head at Mile 35.42, a bolt hole crack at Mile 35.62, and an 80% transverse rail fissure at Mile 35.80. These rail sections were replaced the next day. The north end of the track (Mile 35.80 to Mile 35.98) was not inspected during the internal rail defect testing on 14 April 2015, because cars were present on the track.

According to the TSR, track geometry inspections are not required for the CC Long Siding, and no result was noted on the CC Long Siding track inspection log. However, both turnouts leading to the Class 3 main track must be inspected once a year with a heavy geometry inspection vehicle. The last inspection of the east main track and the 2 turnouts was performed on 11 May 2018. No urgent defects were observed.

Repair work following the occurrence

Internal rail defect testing was performed during remediation of the CC Long Siding track and turnout. Several rail sections and about 400 wood ties, spread along the CC Long Siding track, were replaced.

Safety action taken and safety message

Following the occurrence, CP increased the frequency of rail flaw inspection testing of the CC Long Siding track to 2 times per year.

With respect to other track inspections, although low-tonnage Class 1 tracks are inspected in accordance with applicable standards, a visual inspection of the condition of components cannot detect certain types of track defects. It is therefore possible that defects such as deteriorated ties may not be detected and that the damaged track may remain in service, compromising its integrity.

This report concludes the Transportation Safety Board of Canada's investigation into this occurrence. The Board authorized the release of this report on . It was officially released on .