Railway Investigation Report R12T0038 (Burlington)

Main-track derailment

Via Rail Canada Inc.

Passenger train no. 92

Mile 33.23, Canadian National

Oakville Subdivision

Aldershot, Ontario

The Transportation Safety Board of Canada (TSB) investigated this occurrence for the purpose of advancing transportation safety. It is not the function of the Board to assign fault or determine civil or criminal liability. This report is not created for use in the context of legal, disciplinary or other proceedings. See Ownership and use of content.

-

Table of contents

Summary

On 26 February 2012, VIA Rail Canada Inc. passenger train No. 92 (VIA 92) was proceeding eastward from Niagara Falls to Toronto, Ontario, on track 2 of the Canadian National Oakville Subdivision near Burlington, Ontario. VIA 92, which was operated by 2 locomotive engineers and a locomotive engineer trainee, was carrying 70 passengers and a VIA service manager. After a stop at the station at Aldershot, Ontario (Mile 34.30), the train departed on track 2. The track switches were lined to route the train from track 2 to track 3, through crossover No. 5 at Mile 33.23, which had an authorized speed of 15 mph. At 1525:43 Eastern Standard Time, VIA 92 entered crossover No. 5 while travelling at about 67 mph. Subsequently, the locomotive and all 5 coaches derailed. The locomotive rolled onto its side and struck the foundation of a building adjacent to the track. The operating crew was fatally injured and 45 people (44 passengers and the service manager) sustained various injuries. The locomotive fuel tank was punctured and approximately 4300 litres of diesel fuel was released.

Ce rapport est également disponible en français.

1.0 Factual information

VIA Rail Canada Inc. (VIA) operates up to 503 trains weekly on 12 500 km of track and serves 450 communities across the country. VIA carries on average 4 million customers annually on its fleet of 396 passenger cars and 74 road locomotives. It operates 159 passenger stations, 4 maintenance facilities and employs approximately 3000 people. While VIA owns 223 km of track, most of the track infrastructure it uses is owned and managed by freight railway companies.

In February 2012, VIA passenger train No. 92 (VIA 92) operated each Saturday and Sunday from Niagara Falls, Ontario, to Toronto, Ontario. On 26 February 2012, VIA 92 was made up of a single head-end locomotive (VIA 6444) and 5 Light, Rapid, Comfortable (LRC) coaches (VIA 3454, VIA 3354, VIA 3318, VIA 3319 and VIA 3311). VIA 92 weighed 389 tons and was 510 feet long. It was last inspected at VIA’s Mimico Maintenance Centre, Ontario, on 25 February 2012, with no defects noted.

There were 70 passengers on board: 41 in the 1st coach, 28 in the 2nd coach and 1 in the 3rd coach. A VIA service manager (SM) was stationed in the 2nd coach. The 4th and 5th coaches were empty. VIA 92 was usually staffed with 2 on-board service personnel. However, on that day, no additional staff was available.

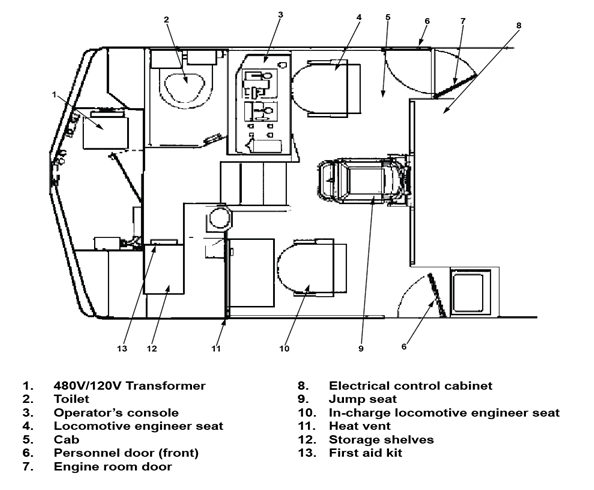

VIA trains are normally operated by 2 qualified locomotive engineers located in the lead locomotive. The operating locomotive engineer (LE) sits at the controls on the right side of the locomotive cab while the in–charge locomotive engineer (ICLE) sits on the left side of the cab and performs the duties of the conductor (see Figure 1).

The LE for VIA 92 had more than 33 years of railway experience, including 28 years as a locomotive engineer. The LE had initially worked as a locomotive engineer for Canadian National (CN) for 24 years before moving to VIA where he had worked for the past 4 years. The ICLE had 34 years of railway experience, including 25 years as a locomotive engineer. The ICLE had initially worked as a locomotive engineer for CN for 21 years before moving to VIA where he had worked for the past 4 years. The LE and ICLE were qualified for their positions, met rest standards and were experienced with the territory. They had worked together as a crew on a regular basis over the previous 16 months.

On this trip, a 3rd operating crew member was in the cab. This crew member was a locomotive engineer trainee who was on this trip as part of VIA familiarization training for trainees. A 3rd person in the cab is usually seated in the jump seat located between the LE and the ICLE. When a trainee accompanies a VIA crew, signal recognition and rules compliance are responsibilities shared equally among all crew members.

The trainee was a qualified locomotive engineer. He had 22 years of railway experience, including 9 years as a locomotive engineer. He had worked as a locomotive engineer for the Ottawa Central Railway (7 years) and for CN (2 years). He had been hired as a trainee by VIA in October 2011. As part of VIA’s locomotive engineer training program, the trainee had completed several assignments between Niagara Falls and Toronto. On some of these assignments, the trainee had been paired with the LE. The trainee met fitness and rest standards.

All 3 operating crew members were based in Toronto. On the day before the accident, the crew had come on duty at 1545 Footnote 1 and had worked westward from Toronto to Niagara Falls on VIA train No. 95 before booking off duty at 2109.

1.1 The accident

On 26 February 2012, the crew came on duty at 1306. Before departing Niagara Falls, the SM provided a pre-departure briefing to the crew. During the briefing, the SM indicated that a wheelchair passenger would be disembarking at Oakville, Ontario. To accommodate this passenger at Oakville, VIA 92 would normally arrive on track 1 adjacent to Oakville Station.

At Niagara Falls, passengers were only seated in the 1st coach (VIA 3454). Prior to departing, the SM made the standard safety announcement using the public address system regarding the safety pamphlet located in the seatback pocket. In accordance with regulatory requirements and VIA procedures, the SM designated and briefed the passengers who were seated near exit windows and side exit doors on emergency procedures.

Passengers who boarded the train at subsequent stations were seated in the 2nd car (VIA 3354), after which the SM once again designated and briefed a number of able-bodied passengers on emergency procedures. During the journey, the doors between the 1st and 2nd cars were left open to make it more convenient to provide service to passengers.

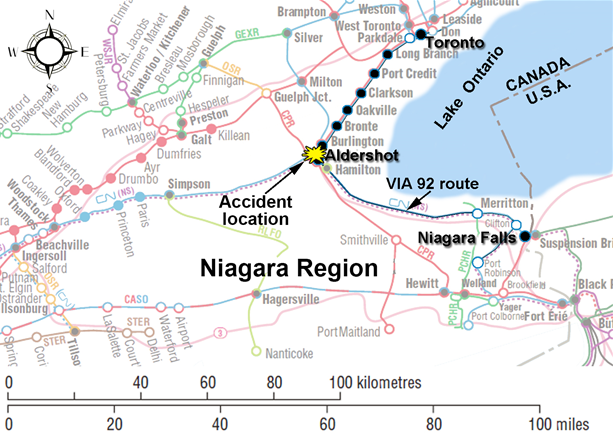

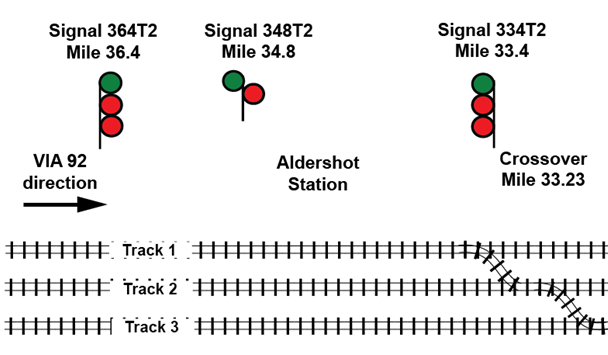

At 1404:40, VIA 92 left Niagara Falls on time destined for Toronto (see Figure 2). VIA 92 was routed on the Grimsby Subdivision from Clifton, Ontario (Mile 2.60), to Hamilton, Ontario (Mile 43.70), where it entered the Oakville Subdivision. Footnote 2 On the Oakville Subdivision, VIA 92 travelled on the north track from Hamilton (Mile 39.30) to Bayview, Ontario (Mile 36.90), where the train was routed eastward on track 2 past Aldershot Station (Mile 34.60) all the way to signal 333T2. This route required VIA 92 to pass controlled signal 364T2 (Mile 36.40) at Snake and advance signal 348T2 (Mile 34.80) at Waterdown on its approach to the Aldershot Station.

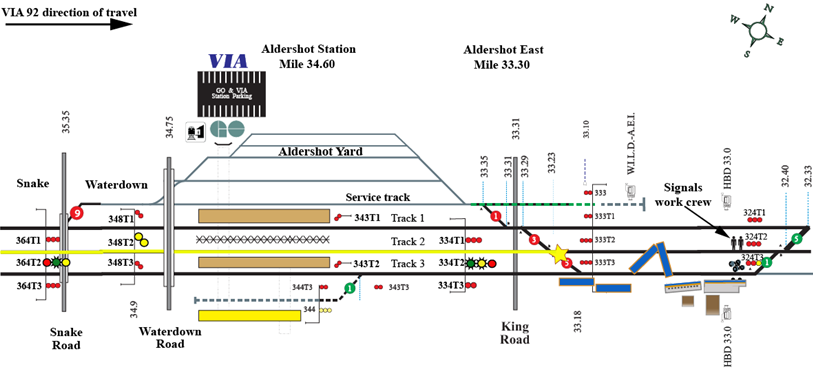

Earlier in the day, a CN signals work crew consisting of a signal maintainer and a technician had been dispatched in response to a trouble call reported by the hot box detector (HBD) at Mile 33.10 (approximately 1000 feet east of the King Road crossing). When the signals work crew arrived at the work site, they parked their vehicle north of track 1 and requested a track occupancy permit (TOP) from the CN rail traffic controller (RTC). At 1404:58, the RTC issued a TOP to the signals work crew, which authorized them with exclusive occupancy of track 2 between signal 333T2 (Mile 33.30) Footnote 3 at Aldershot East and signal 324T2 (Mile 32.40) at Burlington West. Once the TOP was issued, the signals work crew walked over to track 2 and commenced with repairs.

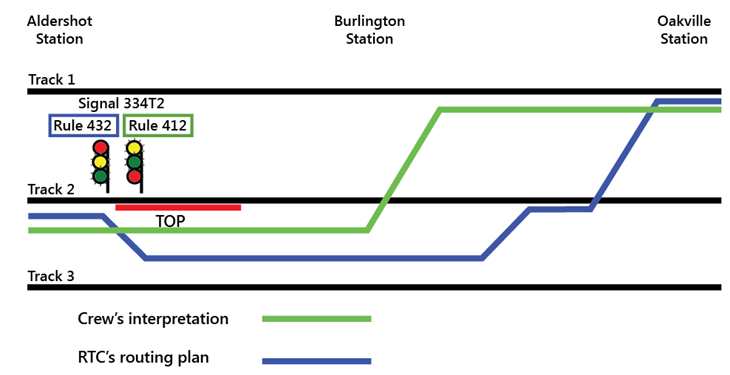

At the request of the VIA Oakville Station manager, the RTC had planned to line the route for VIA 92 to arrive at platform 1 to facilitate the disembarkment of the wheelchair passenger. When planning VIA 92’s route east of Aldershot Station, the RTC had the option to cancel the TOP on track 2. However, given the importance of having the HBD repaired, the RTC opted to route VIA 92 around the TOP on track 2. Subsequently, the RTC lined the track switches to

route the train from track 2 to track 3 through crossover No. 5 (Mile 33.23), which was authorized for a speed of 15 mph. The RTC did not communicate the TOP or route change to the VIA 92 crew, nor was there any requirement to do so.

At 1517:19, VIA 92 arrived at Aldershot Station, which was a regular stop. After this stop, the train was normally (that is, over 99 % of the time) routed straight through on track 2. At 1523:26, the trip to Toronto resumed as VIA 92 departed on track 2 and approached controlled signal 334T2 (see Figure 3).

The signals work crew observed VIA 92 accelerate towards them on track 2. Although the area was designated as anti-whistling, VIA 92 sounded the train horn several times. The signals work crew looked eastward at signals 324T1, 324T2 and 324T3 and they confirmed that signal 324T3 was permissive while signals 324T1 and 324T2 both indicated Stop, verifying that they had protection on track 2. However, from their location, they could not observe the aspect on signals 334T1, 334T2 and 334T3 (Mile 33.40), as these signals faced west towards approaching VIA 92. When they recognized that VIA 92 was not slowing down, they moved to a safe location north of track 1.

At 1525:43, VIA 92 entered crossover No. 5 while travelling at about 67 mph. The locomotive (VIA 6444) leaned northward briefly, then derailed and rolled to the south. The locomotive slid down the embankment and struck the concrete foundation of a building adjacent to the right-of-way. The entire rear truck of VIA 6444, including the traction motors, separated from the locomotive, derailed and came to rest approximately 1000 feet east of the locomotive. It was straddling track 3 near the location where the signals work crew was working moments earlier. The signals work crew immediately contacted the RTC and reported the accident. The RTC cancelled all nearby permissive signals to protect the site against other train movements and initiated emergency response protocols.

1.2 Site examination

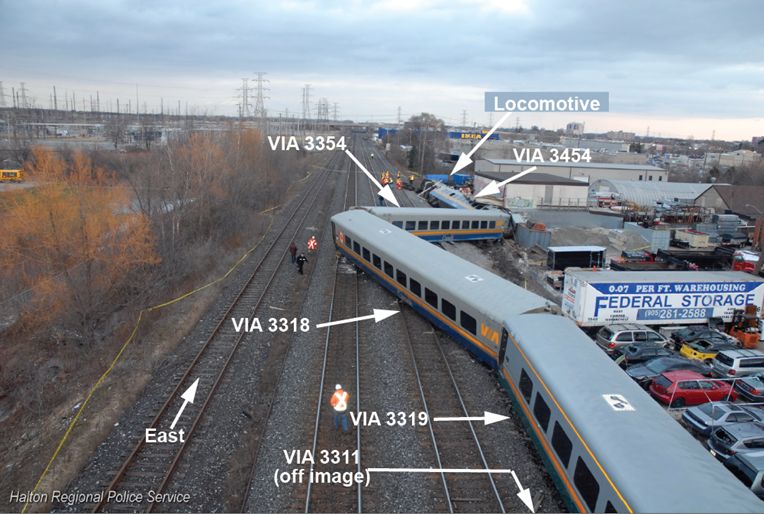

The locomotive and all 5 coaches derailed. In the vicinity of the accident, the tracks are situated at a slightly higher elevation than the surrounding terrain. During the accident, locomotive VIA 6444 and the 1st coach (VIA 3454) slid down the embankment, rolled and came to rest on their sides. The train and its air brake line remained connected and intact. The front locomotive truck was on the side of the embankment, partially attached to the locomotive by cables. The locomotive cab area just above the front nose had struck the foundation of a building adjacent to the track. The building foundation was heavily damaged, while the cab roof had completely collapsed, resulting in extensive damage to the cab interior (see Photo 1).

At the east end of the No. 5 crossover, there were wheel flange impact marks observed on the guard rail and the frog of turnout 5B, indicating that the locomotive wheels had left the north rail near the frog.

The majority of the passengers were travelling in the first 2 coaches, both of which were heavily damaged. The 2nd coach (VIA 3354) and the 3rd coach (VIA 3318) had jackknifed. The front portion of the 2nd coach had slid down the embankment. The 2nd and 3rd coaches had come to rest foul of track 2. The 4th coach (VIA 3319) and the 5th coach (VIA 3311) remained upright on the right-of-way just south of track 3 and sustained minor impact damage (see Photo 2).

1.3 Emergency response and evacuation

1.3.1 Initial emergency response

At the time of the accident, the SM was in the 2nd coach checking the tickets of passengers who had just boarded the train in Aldershot. Immediately following the accident, the SM conducted visual and verbal checks with passengers in the 2nd car to assess the extent of injuries to the passengers. The SM then tried to contact the locomotive crew with no success, following which the SM made an emergency radio broadcast on the standby channel and then an emergency call on the cell phone to the RTC.

During the derailment, the vestibule between the 1st coach and the 2nd coach broke apart, leaving the respective end doors accessible. The SM exited the 2nd coach through the east-end door and entered the 1st coach through its adjoining partially open door. Together with some able-bodied passengers, the SM provided initial assistance to the passengers. All passengers in the 1st coach remained in the coach until emergency responders arrived. The passengers in the 2nd coach disembarked on their own initiative. While some of these passengers gathered at a meeting point, others departed the site without seeking medical aid.

1.3.2 Subsequent emergency response and evacuation

The accident occurred just east of the King Road level crossing, making the accident site accessible for emergency vehicles, equipment and responders. The Halton Regional Police, Ontario Provincial Police, Emergency Medical Services (EMS) and 3 crews from the Burlington Fire Department arrived at the accident site within minutes.

An incident command post was established for the responders and a unified command structure was put in place to coordinate the activities of the various response agencies. The SM remained and provided assistance throughout the evacuation. CN staff, VIA personnel and other passengers also assisted with rescue and recovery efforts.

Since the 1st coach was on its side with its roof against the building, the available emergency exits (that is, windows and doors) were located on the side of the coach that was facing up (see Photo 3). This presented some initial difficulties and delays for evacuation as the emergency responders had to first gain access to the coach interior. An emergency responder climbed onto the side of the coach and forced entry into the car by breaking the window on the side door. Another emergency responder gained access through the partially open west end door. Once inside the coach, triage of passenger injuries commenced. Tarps were placed over some passengers to protect against falling glass as an emergency exit window was broken to aid with the evacuation.

While the west end door of the 1st coach was partially open, it was bent during the accident and could not fully open (see Photo 4). Subsequently, the door was cut away to aid with the evacuation. Additional ladders were provided to allow emergency responders to gain access to the coach and to allow passengers to evacuate from the coach. It was difficult for many of the passengers and emergency responders to make their way over the seats of the overturned coach to the available exits.

About 20 passengers were evacuated through the windows while the others were evacuated through the west end door. Mobile passengers were first evacuated, followed by those who were trapped and/or more seriously injured. During the evacuation, 4 passengers were carried and removed using backboards and stokes baskets.

To extricate the operating crew, the locomotive roof was cut away and removed. The LE, ICLE and trainee were located in the area of the locomotive cab control stand and had sustained fatal injuries. It was determined that the LE was at the controls at the time of the accident.

The passengers were initially treated at the staging area by EMS. Those who were injured or required more detailed examination were transferred to area hospitals. A total of 13 ambulances and 2 helicopter air ambulances were dispatched to transport the injured.

Since some passengers had already departed the site, it was initially challenging to determine the number of people who were on board. Following a review of VIA records, the number of people (that is, VIA crew, on-board service personnel and passengers) was confirmed and accounted for.

The locomotive fuel tank was dented and punctured along the bottom edge (see Photo 5). Subsequently, approximately 4300 litres of diesel fuel was released. During site clean-up, any fuel that had pooled on the ground was removed by vacuum truck. Contaminated soil was removed and the area backfilled. Monitoring wells were drilled in order to monitor site remediation.

1.4 Injuries

During the accident, the passengers were bounced around and many were ejected or fell out of their seats. A total of 44 passengers and the SM were transported to hospital for various injuries. This included 30 of the 41 passengers in the 1st coach, 13 of the 28 passengers in the 2nd coach and the sole passenger in the 3rd coach.

The most common diagnosis included bruises, lacerations and minor head, neck, shoulder and lower back injuries. Three passengers suffered rib fractures and one passenger sustained a fractured arm. The majority of injuries were sustained by people being ejected or falling out of a seat, being struck by another person, being struck by one of various items that came loose and moved freely within the coach or a combination of these. Seat restraints are not provided for locomotives or passenger coaches nor are they required by regulation.

1.5 Weather

The weather was sunny with clear visibility and the temperature was 0°C.

1.6 Recorded information

Recorded events between Niagara Falls and the accident location are shown in Table 1. Event times have been normalized to coincide with the locomotive event recorder (LER).

| Action | Time | Mile | mph | Brake pipe (psi) | Brake cyl. (psi) | Throt-tle | Bell | Horn | Emerg. brake app. |

|---|---|---|---|---|---|---|---|---|---|

| VIA 92 crew on duty – Niagara Falls | 1306:00 | ||||||||

| VIA 92 departs Niagara Falls | 1404:40 | ||||||||

| TOP issued to CN signal maintainer between signal 333T2 (Aldershot East) and signal 324T2 (Burlington West) | 1404:58 | ||||||||

| VIA 92 departs Grimsby | 1447:39 | ||||||||

| Crossover No. 5 lined from track 2 to track 3 for VIA 92 around CN signals work crew at work | 1512:56 | ||||||||

| VIA 92 passes controlled signal 364T2 (Snake) displaying a Clear to Limited signal (Rule 406) with aspects Y/FG/R | 1514:42 | 36.40 | 41.3 | 98 | 0 | 8 | Y | Y | |

| VIA 92 passes advance signal 348T2 (Waterdown) displaying Clear to Slow signal (Rule 409) with aspects Y /Y | 1516:23 | 34.88 | 53.2 | 90 | 0 | N | |||

| VIA 92 arrives at east end of Aldershot Station on track 2 | 1516:45 | 34.62 | 23.9 | 86 | 13 | 0 | Y | ||

| VIA 92 arrives at Aldershot Station | 1517:19 | 34.50 | 0 | ||||||

| VIA 92 departs Aldershot Station on track 2 | 1523:26 | 1 | 6 | Y | |||||

| VIA 92 activates bell at whistle post | 1525:18 | 33.67 | 58.7 | 96 | 0 | 6 | Y | N | N |

| King Road crossing gates activated | 1525:21 | ||||||||

| LE moves throttle from 6 to 8 | 1525:22 | 33.60 | 59.7 | 96 | 0 | 8 | Y | N | N |

| Horn applied intermittently | 1525:26 | 33.52 | 61.5 | 96 | 0 | 8 | Y | Y | N |

| VIA 92 passes controlled signal 334T2 (Aldershot East) displaying a Slow to Limited signal (Rule 432) with aspects R/FY/FG | 1525:33 | 33.40 | 64.6 | 96 | 0 | 8 | Y | Y | N |

| Horn blast | 1525:37 | 33.32 | 65.5 | 96 | 0 | 8 | Y | Y | N |

| Throttle moved from 8 to 6 | 1525:39 | 33.31 | 66.6 | 96 | 0 | 6 | Y | Y | N |

| Throttle moved from 6 to | 1525:40 | 33.30 | 66.6 | 96 | 0 | 3 | Y | Y | N |

| Horn off | 1525:41 | 33.26 | 66.6 | 96 | 0 | 3 | Y | N | N |

| Second horn blast | 1525:42 | 33.25 | 66.6 | 96 | 0 | 3 | Y | Y | N |

| Locomotive enters No. 5 crossover | 1525:43 | 33.23 | 66.9 | 96 | 0 | 3 | Y | Y | N |

| Throttle moved from 3 to idle (0) and locomotive derails exiting No. 5 crossover | 1525:44 | 33.19 | 66.6 | 96 | 0 | 0 | Y | Y | N |

| Locomotive comes to rest on side | 1525:51 | 33.11 | 0 | 98 | 0 | 0 | Y | N | N |

The locomotive was not equipped to record audio of in-cab conversations between crew members. There were no forward-facing or in-cab video recorders installed on the locomotive. None of the operating crew cell phones were in use at the time of the accident.

1.7 TSB re-enactment

On 04 March 2012, a re-enactment of some of the key events was conducted from the head end of another eastbound VIA passenger train routed through Aldershot Station on track 2. The re-enactment confirmed the following:

- All signals were clearly visible from the locomotive cab throughout the journey.

- It was unlikely that the sun interfered with the crew’s ability to identify the signals.

- Although signal 334T2 was visible from the locomotive cab while stopped at Aldershot Station, the precise signal indication would have been difficult to identify from that distance (approximately 4700 feet).

1.8 Subdivision and track information

Train movements on the Oakville Subdivision are governed by the Centralized Traffic Control System (CTC), as authorized by the Transport Canada (TC)–approved Canadian Rail Operating Rules (CROR) and supervised and directed by an RTC located in Toronto. Train traffic consists of approximately 49 GO Transit commuter trains, 28 freight trains and 18 VIA passenger trains per day. The maximum authorized timetable speed for passenger trains in the area of the accident is 95 mph. On the day of the accident, General Bulletin Order (GBO) 5058 required that speed be reduced to 80 mph on track 2 between Mile 32.00 and Mile 36.40.

In the vicinity of the derailment, the Oakville Subdivision consists of 3 main tracks (that is, tracks 1, 2 and 3). Track 1 is generally used by freight traffic to access CN’s Aldershot yard. Track 3 is normally used by GO Transit commuter train traffic. VIA trains are usually routed through Aldershot on track 2.

Track 1 and track 3 were equipped with 136-pound continuous welded rail. Track 2 consisted of 132-pound continuous welded rail. The rails were laid on 14-inch and 16-inch double-shouldered tie plates fastened to hardwood ties with 2 spikes per plate. The rail was box anchored every second tie. The cribs were full with crushed rock ballast and the drainage was good. The track was inspected in accordance with regulatory and company requirements and was in good condition.

In the vicinity of Mile 33.23, there were 3 crossovers (that is, No. 1, No. 3 and No. 5). These crossovers enabled eastbound and westbound traffic to switch between the Aldershot service track, which accesses the Aldershot Yard, and the 3 main tracks. Each crossover was equipped with a No. 12 turnout at each end. No. 12 turnouts have a maximum authorized speed of 15 mph. These turnouts have 36-foot, 7-inch-long switch points with point rollers that facilitate point movement. Footnote 4 Each crossover was made up of 136-pound running rail and rail bound manganese frogs. The rail was fixed with elastic fasteners to rolled tie plates that were secured to the ties with lag screws. All crossover ties were box anchored, the cribs were full with crushed rock ballast and the drainage was good.

The last inspection of the crossover switches had been conducted by hi-rail on 26 February 2012, the day of and just prior to the accident. A visual walking inspection had been performed for crossover No. 1 and No. 5 on 06 February 2012, with no defects found. A visual walking inspection was performed on crossover No. 3 just after the accident, with no defects found.

The crossovers at this location were primarily used by freight trains entering and leaving the Aldershot Yard. In this area, normal routing for eastbound VIA trains was straight through on track 2. For eastbound VIA trains, crossing over from track 2 to track 1 is usually performed at Burlington West (Mile 32.20) where the crossover consists of the higher speed No. 20 turnouts. The Burlington West crossovers are equipped with No. 20 turnouts, which have a greater distance between the switch point and the frog, allowing for speeds of up to 45 mph.

1.9 Protection for track work

When accessing main line track to perform maintenance or repairs, work crews are required to obtain track protection to protect them from trains. In CTC areas, the work crew can obtain protection to access the track under Rule 842 (Planned Protection) or Rule 849 (TOP):

- In practice, planned protection is usually requested well in advance and is included in a Tabular General Bulletin Order (TGBO), which is issued directly to operating crews.

- TOPs are used for track inspections, for track work performed on short notice or for track work necessitated by emergency situations. In CTC territory, train crews would not be advised of a TOP as they are specifically trained and expected to react to the progression of wayside signal indications as presented along the route.

At CN, small track repairs can also be performed under Safety Watch protection, which requires that 1 member of a 3-person work crew is dedicated to watching for oncoming trains or equipment while the other work crew members perform the work. When a train crew encounters workers on the track under Safety Watch protection, the train crew will typically sound the horn intermittently to capture the work crew's attention with the expectation that they will clear the track. In December 2011, following an accident where a CN Engineering Services employee was struck by a VIA train while performing track work under Safety Watch, CN suspended the use of Safety Watch as a protection method on all class 5 double-track territory (TSB investigation report R11T0161). While CN had communicated this information internally to its engineering personnel, it was not communicated to any other CN or VIA staff, nor was it required to be.

1.10 Centralized traffic control system

CTC is a system to control train movements that employs interconnected track circuits and field signals (that is, controlled, advance, and intermediate signals). Computer displays and controls are installed in the RTC office. The design of the system is such that trains are given a series of progressive track-side signal indications that require train crews to take action based on the signal displayed. In Canada, CTC does not provide any form of automatic enforcement to slow or stop a train if it were to pass a Stop signal or other point of restriction.

When an RTC requests controlled signals for trains, the signal system determines how permissive the signals will be. In the RTC office, track occupancy between controlled locations is displayed on a computer screen. Train movements approaching controlled signals are governed by advance signals that are automatically actuated by the presence of a train located between the controlled signals. The displayed signal indications convey information to train crews that indicates the speed at which they may operate and how far they are permitted to travel. Signal indications also provide protection against certain conditions such as an occupied block, broken rail, or an open switch lined against the movement.

1.11 Canadian rail operating rules and compliance

The TC–approved CROR contain the following definitions with regard to speed:

- LIMITED speed—a speed not exceeding 45 mph;

- MEDIUM speed—a speed not exceeding 30 mph; and

- SLOW speed—a speed not exceeding 15 mph.

Rule 33 (Speed Compliance) states the following:

If speed requirements for their movement are exceeded, crew members must remind one another of such requirements. If no action is then taken, or if the employee controlling the engine is observed to be non-responsive or incapacitated, other crew members must take immediate action to ensure the safety of the movement, including stopping it in emergency if required.

Signal recognition and compliance is governed in part by Rule 34 (Fixed Signal Recognition and Compliance) which states that:

- The crew on the controlling engine of any movement and snow plow foremen must know the indication of each fixed signal (including switches where practicable) before passing it.

- Crew members within physical hearing range must communicate to each other, in a clear and audible manner, the indication by name, of each fixed signal they are required to identify. Each signal affecting their movement must be called out as soon as it is positively identified, but crew members must watch for and promptly communicate and act on any change of indication which may occur.

The following signals/operating signs must be communicated:

- Block and interlocking Footnote 5 signals;

- Rule 42 and 43 signals;

- One mile sign to interlocking;

- One mile sign to hot box detector;

- Stop sign;

- OCS begins sign;

- Red signal between the rails;

- Stop signal displayed by a flagman;

- A switch not properly lined for the movement affected;

- One mile to Cautionary Limit Sign; and

- Cautionary Limit Sign.

- If prompt action is not taken to comply with the requirements of each signal indication affecting their movement, crew members must remind one another of such requirements. If no action is then taken, or if the employee controlling the engine is observed to be incapacitated, other crew members must take immediate action to ensure the safety of the movement, including stopping it in emergency if required.

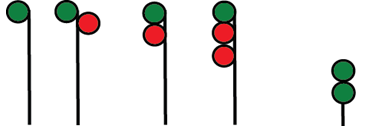

CROR Rules 405 to 440 govern signals that are utilized in CTC territory. The signal aspects, otherwise known as lights or indications, are differentiated by colour, position of colours, flashing of the lights, or combinations thereof. The signals can be displayed using 1, 2 or 3 lights. Signals are interconnected in series to provide train crews with a progressive indication. Crews are trained on this principle of progression, and in the field, continuously experience it. A “Red” light on top of any aspect is consistently used with rules with a restriction of speed. The signal aspects and associated rules that are relevant to this occurrence are detailed in Table 2.

| Signal aspects displayed | CROR Rules |

|---|---|

| Rule 405—Clear Signal—Proceed (at track speed). | |

| Rule 406—Clear to Limited—Proceed, approaching next signal at LIMITED speed (not exceeding 45 mph). | |

| Rule 409—Clear to Slow—Proceed, approaching next signal at SLOW speed (not exceeding 15 mph) | |

| Rule 412—Advance Clear to Limited—Proceed, approaching second signal at LIMITED speed (not exceeding 45 mph) | |

| Rule 432—Slow to Limited—Proceed, SLOW speed (not exceeding 15 mph) passing signal and through turnouts, approaching next signal at LIMITED speed (not exceeding 45 mph) |

Train crews must be familiar with all signal indications specified in the CROR and are required to control their trains in accordance with these rules. Crew members are also expected to know their operating territory, including the location of individual signals. This knowledge is used to facilitate the detection of signals and to help recognize the presence of an imperfectly displayed signal or absence of a signal.

Perception of signals can be viewed as a 3-step process: detect, discriminate and decide on the aspect displayed. This process can be rapid. When the signals are not obscured or obstructed and there is good visibility, signal perception (that is, recognition) can be accomplished rapidly from relatively long distances. However, signal perception can be affected by the crew's fitness for duty and by perceptual context or mental model.

1.12 Signals displayed for eastbound trains stopping at Aldershot

An eastbound passenger train travelling on track 2 of the Oakville Subdivision, usually with a stop at Aldershot Station (Mile 34.60), would encounter the following signals governing its movement:

- controlled signal 364T2 (Mile 36.40);

- advance signal 348T2 (Mile 34.80); and

- controlled signal 334T2 (Mile 33.40) just before crossover No. 5 at Mile 33.23.

1.12.1 Signal indications displayed when lined through on track 2

When the crossover at Mile 33.23 is lined straight through on track 2, with no speed restrictions in place and permissive signals displayed at Aldershot East (Mile 33.40) and Burlington West (Mile 32. 40), the signal progression is as follows (see Figure 4):

- Signal 364T2 displays a Clear signal (Rule 405) indication with aspects Green over Red over Red (G/R/R)—proceed at track speed;

- Signal 348T2 displays a Clear signal (Rule 405) indication with aspects G/R—proceed at track speed; and

- Signal 334T2 displays a Clear signal (Rule 405) indication with aspects G/R/R—proceed at track speed.

In the 3 months preceding the accident, eastbound VIA 92 arrived at Aldershot Station 27 times. On 26 of these occasions, VIA 92 stopped at the station (that is, 97 % of the time). In addition, VIA trains are routed through the 15 mph crossover at Aldershot East less than 1 % of the time in relation to all crossover moves between Aldershot and Burlington. Based on the scheduled arrivals at Aldershot and the crossover routing decisions, VIA 92 encountered a clear signal indication east of Aldershot Station more than 99 % of the time.

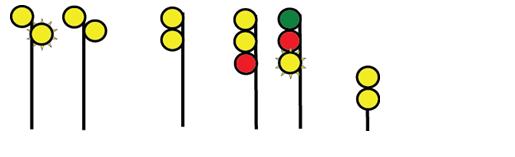

1.12.2 Signal indications displayed when crossover lined from track 2 to track 3

When the crossover at Mile 33.23 is lined to bring a train from track 2 to track 3, the signal progression (see Figure 5) is as follows:

- Signal 364T2 displays a Clear to Limited signal (Rule 406) with aspects Yellow over Flashing Green over Red (Y/FG/R)—proceed, approaching next signal at limited speed (not exceeding 45 mph);

- Signal 348T2 displays a Clear to Slow signal (Rule 409) with aspects Yellow over Yellow (Y/Y)—proceed, approaching next signal at slow speed (not exceeding 15 mph); and

- Signal 334T2 displays a Slow to Limited signal (Rule 432) with aspects Red over Flashing Yellow over Flashing Green (R/FY/FG)—proceed, slow speed (not exceeding 15 mph) passing the signal and through turnouts, approaching next signal at limited speed (not exceeding 45 mph). For eastbound VIA trains between Niagara Falls and Burlington West, this signal combination can only be displayed at Signal 334.

The electronic circuits for Signal 334T2 are such that the signal cannot display an Advance Clear to Limited (Rule 412) aspect (FY/FG/R). However, train crews would only be concerned with and focussed on aspect display and would not know specific details of circuitry.

1.13 Signal testing

The CTC on the Oakville Subdivision was upgraded from a relay-based logic system to a Geographic Signalling System (GEO) solid-state microprocessor-based system. The field signals at Aldershot East for track 1 (334T1) and track 2 (334T2) were 3-colour light aspect assemblies (Model 20R) while the signal for track 3 (334T3) consisted of a 2-colour light aspect assembly. In each case, the aspect assemblies were positioned one over the other with the top assembly identified as the “A” head, the middle as “B” head and the bottom as “C” head respectively.

Inside each aspect assembly, there are 3 lights positioned one over the other with a total of 9 lights for signals 334T1 and 334T2, and 6 lights for signal 334T3. Incandescent bulbs behind each coloured lens display the proper combination of red, yellow and/or green lights. Only one light in each assembly can be lit at one time. Attempts to activate 2 lights in one assembly would force the signal to its most restrictive state (red). The individual signals face oncoming traffic and are mounted on an aluminium gantry located above the right-of-way, positioned directly over the track that they govern (see Photo 6).

Immediately following the accident, the wayside signals governing VIA 92's movement approaching Aldershot East (Mile 33.30) were inspected and tested by CN Signals & Communications (S&C) technicians. All signal control cables and underground control circuits were tested for short circuits. The aspect lamp voltages were taken and battery ground tests were conducted. Through these tests, the signal system was determined to be functioning in accordance with CROR, CN Signals & Communications General Instructions, Code and Practices specifications, and approved plans.

To further verify the signalling system, the TSB contracted an independent signal consultant to inspect the signals and review all related data. The consultant confirmed that

- the signal hardware and software had been installed according to plan;

- the signalling system had worked as designed; and

- the signalling system complied with established block and interlocking signal rules described in the CROR.

On 08 March 2012, CN technicians (in the presence of TSB investigators and a consultant) performed procedures CN GI-309 (Test Ground Resistance) and CN Gl-312 (Testing Wire and Cable Insulation Resistance). These tests were performed on the wiring between the signal bungalow and the 3-colour light aspect assemblies of signal 334T2. The results were within tolerance and the integrity of the wiring was confirmed. The inside of the signal heads were also inspected and did not exhibit any damage or corrosion. Each of the aspects for signal 334T2 was equipped with light bulbs (part number RR-10128-SF) manufactured by GEMS. The measured voltage for each of the lights was within the accepted standards. In addition, CN performed a second download of the data stored in the signal bungalow that re-verified the data previously downloaded.

The signal inspection and testing concluded that

- on 26 February 2012, immediately before the accident, the crossover at Mile 33.23 was lined to bring VIA 92 from track 2 to track 3.

- the following wayside signals were displayed governing the route of VIA 92 as it approached Aldershot East (Mile 33.30):

- Signal 364T2 displayed a Clear to Limited signal (Rule 406) with aspects Y/FG/R;

- Signal 348T2 displayed a Clear to Slow signal (Rule 409) with aspects Y/Y; and

- Signal 334T2 displayed a Slow to Limited signal (Rule 432) with aspects R/FY/FG.

1.14 VIA locomotive engineer training

All VIA locomotive engineers undergo in-class refresher training 1 day per year, which includes a review of the signal rules. They are also tested on signal rules once every 3 years and must obtain a score of 100 % to maintain their VIA qualification. Although the test does not include all signal rules, the questions are randomly selected, requiring the locomotive engineer to be prepared for all the rules.

VIA provides its locomotive engineers with self-training aids for signal rules. VIA locomotive engineers also continually exercise signal rules recognition as a crew while performing their duties and during periodic VIA efficiency testing.

For operating crews, VIA hires either qualified locomotive engineers (trainees), certified locomotive engineers who need to complete their qualification or internal employees as student locomotive engineers. In the Toronto Terminal, the training period for qualified locomotive engineers is normally from 4 to 8 months. During training, signal rules are reviewed in detail. A trainee must achieve a score of 100 % on the signal rules test in order to pass.

In this case, the trainee was in the final stage of training and was within a few weeks of fully qualifying, after having progressed at a relatively fast pace. The trainee had already achieved 100 % on the signal rules test. The final stage of training consisted of familiarization assignments in the cab. During this type of training, the trainee would occasionally operate the locomotive under the supervision of the operating crew.

1.15 Situational awareness and mental models during train operation

Situational awareness (SA) in relation to operational matters refers to the operator knowing what is happening in the immediate environment. There are 3 stages of SA: Footnote 6

- “Perception” refers to the recognition that new unambiguous cues exist.

- “Comprehension” refers to understanding the order of importance of the new cues.

- “Projection” refers to the ability to forecast future events based on information given.

A train crew's SA comes from various information sources. These can include radio transmissions, signal indications, in-cab displays, observation of the track, environmental conditions and written information. Railway rules and operating instructions also affect SA. For example, CROR and General Operating Instructions (GOI) provide information that operating crews are required to use. When operating a train, decisions and actions greatly depend on the crew's assessment and understanding of the operational situation.

The overall understanding of a situation is based on experience, knowledge and perception of external cues resulting in a mental model. It is difficult to alter a mental model once developed, particularly in a short period of time. To change one's thinking, the existing model must be superseded by another. New information must be provided that is sufficiently noticeable and compelling to result in an update of the mental model

Accurate SA is highly dependent on switching attention between different information sources during which people can get trapped in a phenomenon called attention narrowing or tunnelling. When succumbing to tunnelling, they lock in on certain cues or features of the environment they are trying to process, and will either intentionally or inadvertently drop their scanning behaviour. In these cases, people will believe that this limited focus is sufficient because the situation they are attending to is most important in their minds. In other cases, people can fixate on certain information and forget to reinstate their information scan. Either situation can result in their SA being inaccurate. The reality is that keeping at least a high-level

understanding of what is happening across the board is a prerequisite to being able to know that certain factors are indeed still more important than others. Otherwise, it is often the neglected aspects of the situation that prove to be the fatal factors in loss of SA.Footnote 7

1.16 Additional defences for signal indications

With respect to train operations, the railways and TC have based their safety philosophy on a cornerstone of strict rules compliance. While regulatory compliance is necessary for accident prevention in transportation, regulatory compliance alone is not sufficient to maintain safety in a complex transportation system. Organizations that place excessive reliance on strict regulatory compliance tend to believe that the safety rules they have developed are invulnerable to human error. A rule-book culture can produce an attitude that assumes that all accidents are the result of individual failures to follow the rules. Unfortunately, in a complex system such as transportation, even the most rigorous set of rules will not cover every contingency and interpretation by individuals will be required to cover unanticipated situations. Even the most motivated and experienced employees are subject to the normal slips, lapses and mistakes that characterize human behaviour. The defence-in-depth philosophy advocated by safety specialists for complex systems seeks multiple and diverse lines of defence to mitigate the risks of normal human errors.

For many years, the railway industry in Canada has relied on crew compliance with wayside track signals that provide train crews with a series of signal indications requiring crew actions relative to the signals displayed. In this context, train crews are expected to react to the progression of wayside signal indications. RTCs will minimize the amount of information passed on to operating crews to reduce the risk of anticipation that can result in crew expectation bias related to the signals ahead. The level of safety afforded by wayside signal systems has not advanced significantly beyond their original design, which dates back over 100 years. However, high-speed passenger trains now share track with freight trains and the overall pace of rail transportation has increased since wayside signals were first introduced.

Following the investigation into the 1998 train collision involving 2 Canadian Pacific Railway (CPR) trains near Notch Hill, British Columbia (TSB investigation report R98V0148), the Board determined that backup safety defences for signal indications were inadequate. The Board recommended that

The Department of Transport and the railway industry implement additional backup safety defences to help ensure that signal indications are consistently recognized and followed.

Transportation Safety Recommendation R00-04 (issued February 2001)

Action to date on the deficiency has resulted in procedural improvements implemented by CPR with its crew resource management practices. While there has been some safety benefit, administrative or procedural defences are not always adequate to protect against an operating crew misinterpreting and/or misperceiving wayside signal indications. TC and the railways are exploring the potential for current locomotive fleet computer systems to include signal recognition and air brake control capabilities. However, to date, there has been no formal strategy developed to adapt either emerging technology or existing on-board computer systems to provide fail-safe physical train control defences. Therefore, the Board reassessed the response to Recommendation R00-04 to remain Satisfactory in Part.

1.17 TSB investigations involving misinterpretation of rules or signals

Since 2007, the TSB has conducted 5 investigations into train collisions or derailments where the misinterpretation and/or misperception of wayside signal indications by an operating crew was a cause or contributing factor. These investigations include

- R11E0063 (Bailey) – On 23 June 2011 at approximately 0625 Mountain Daylight Time, CN freight train Q10131-21, proceeding westward at 25 mph on the Wainwright Subdivision, collided with the tail end of CN freight train A41751-23 at Mile 262.30. As a result of the collision, 2 intermodal flat cars derailed (3 car bodies) and locomotive CN 2234 was damaged.

- R10Q0011 (Saint-Charles-de-Bellechasse) – On 25 February 2010, VIA train No. 15 (VIA 15) was proceeding westward from Halifax, Nova Scotia, to Montréal, Quebec. At approximately 0425 Eastern Standard Time near Saint-Charles-de-Bellechasse, Quebec (Mile 100.78 of the CN Montmagny Subdivision), the train entered a siding switch, which had an authorized speed of 15 mph, while travelling at approximately 64 mph. Two locomotives and 6 passenger cars derailed. Two locomotive engineers and 5 passengers were injured. In this accident, advance knowledge of the location of an opposing CN train influenced the crew's expectation that they would not be taking the siding.

- R10V0038 (KC Junction) – On 03 March 2010 at about 1410 Pacific Standard Time, CPR train 300-02, operating eastward on the north track of the Mountain Subdivision approaching KC Junction, British Columbia, side collided with westbound CPR train 671-037 when it was departing Golden from the north track through the crossovers onto the south track. As a result of the collision, 3 locomotives and 26 cars derailed. The crew members of train 300-02 were transported to hospital for observation.

- R09V0230 (Redgrave) – On 30 October 2009 at about 2225 Pacific Daylight Time, CPR train 355-429, operating westward on the signalled siding track at Redgrave, British Columbia (Mountain Subdivision), side collided with eastbound CPR train 110-30 that had stopped on the main track. As a result of the collision, 2 locomotives and 6 cars derailed.

- R07E0129 (Peers) – On 27 October 2007 at 0505 Mountain Daylight Time, the crew on CN train A41751-26 (train 417), operating westward on the main track of the Edson Subdivision, initiated an emergency brake application approximately 475 feet from a stop signal at the west end of Peers, Alberta. The train was unable to stop prior to passing the signal and collided with eastbound CN train M34251-26 (train 342) that was entering the siding. As a result of the collision, train 417's locomotives and 22 cars derailed and 5 cars on train 342 derailed.

1.18 Train control systems that protect against signal misinterpretation

The rail industry has developed technology to address the risk of misinterpreting or not following signal indications. The technologies currently in use include

- Proximity detection

- Cab signalling systems

- Positive train control

- Automatic Trainstop at Toronto Transit Commission (TTC)

- Computer-based train control on Scarborough Light Rail System (TTC)

- Speed control system at TTC

- Train control systems at Amtrak

1.18.1 Proximity detection

A proximity detection device was developed and implemented by Quebec North Shore & Labrador Railway after a 1996 collision involving 2 of its trains (TSB investigation report R96Q0050). The proximity detection device is designed to trigger penalty braking if a train crew or track unit operator does not acknowledge the alert warning status when they come within a predetermined distance of another movement. Except for limited trials, no similar systems have been implemented on other Canadian railways.

1.18.2 Cab-signalling systems

Cab signalling is a communications system that provides track status information to a display device mounted inside the locomotive cab. The simplest systems display the wayside signal indication while more advanced systems also display maximum permissible speeds. The cab signalling system can be combined with automatic train control (ATC) to warn operating crews of their proximity to points of restriction and to initiate enforcement action to slow or stop a train.Footnote 8Cab signals can reduce the risk of signal recognition errors.

In 1922, the United States Interstate Commerce Commission (ICC) made a ruling that required United States railroads to install some form of ATC in one full passenger division by 1925. In response to this ruling, the first cab signalling systems were developed and put into use in the United States. Footnote 9 Cab signalling systems have evolved and remain in use in some United States passenger train corridors. In Canada, there is currently no cab signalling system in use by freight or passenger railways.

1.18.3 Positive train control

Positive train control (PTC) is an emerging train control technology that is designed to prevent

- train-to-train collisions,

- overspeed derailments,

- incursions into work zone limits, and

- movement of a train through a switch left in the wrong position.

If the operating crew does not initiate an adequate response, the PTC system would automatically slow or stop the train.

In the United States, the PTC technology has been under development for many years. The following is a summary of the major events that have influenced the development of PTC:

- Following the investigation of the head-on collision of 2 Penn Central commuter trains near Darien, Connecticut, United States, on 20 August 1969, in which 4 people were killed and 45 people were injured, the United States National Transportation Safety Board (NTSB) recommended that the United States Department of Transportation (DOT) Federal Railroad Administration (FRA) study the feasibility of requiring a form of automatic train control system to protect against train operator error in order to prevent train collisions.

- After the rear-end collision involving a Boston and Maine Corporation commuter train and a Consolidated Rail Corporation (Conrail) freight train on 07 May 1986, in which 153 people were injured, the NTSB recommended that the FRA publish standards requiring the installation and operation of a train control system that would provide for positive train separation (NTSB Recommendation R-87-16, May 1987).

- In 1990, when the NTSB first established its Most Wanted List of transportation safety improvements, it included the issue of positive train separation, which was later changed to PTC.

- In September 1997, the FRA asked its Railway Safety Advisory Committee (RSAC) to address the issue of PTC. A PTC Working Group, which included TC, was formed. In 1999, the working group submitted its report defining the core functions of PTC.

- In 2002, the need for safety improvements was again highlighted when a freight train and a commuter train collided head on in Placentia, California.

- On 12 September 2008, a collision between a Metrolink passenger train and a Union Pacific freight train in California resulted in 25 fatalities and more than 135 serious injuries.

The Metrolink accident prompted the passage of the Rail Safety Improvement Act of 2008, which mandated that, by 2015, PTC be installed on many higher risk rail lines in the United States. However, due to a number of technical challenges, it is anticipated that the United States implementation of PTC will be delayed beyond the 31 December 2015 deadline.

In Canada, there are currently no PTC systems in use by freight or passenger railways and there are no planned PTC installations. Any application of PTC in Canada likely would not occur for a number of years after the United States implementation is complete. However, to meet the PTC requirements for United States operations, both CN and CPR have PTC implementation plans:

- As part of CPR's implementation plan, 460 high horsepower (HHP) locomotives and 110 road and yard switchers will be equipped with the required on-board systems. CPR will install PTC on approximately 1660 miles of track in the United States.

- As part of CN's PTC implementation plan, 820 HHP locomotives and 180 low horsepower locomotives will be equipped with the required on-board systems. CN will install PTC on approximately 3720 route miles of track in the United States.

For both CN and CPR, the PTC system will be based on the Interoperable Electronic Train Management System (I-ETMS). CN will install it on 41 subdivisions, and CPR will install it on 17 subdivisions, corresponding respectively to 62 % and 89 % of their total United States route miles (excluding yard limits). The I-ETMS is a locomotive-centric, train control system that uses a combination of locomotive, office and wayside data that are integrated using a radio network. This system provides the following functions:

- alert train crews to pending authority and speed limit violations, including passing a stop signal;

- stop trains before exceeding authority and speed limits, including signals at stop;

- interrogate upcoming wayside signals, and switches, in a train route when operating in I-ETMS territory; and

- protect work zone limits by enforcing compliance with work zone restrictions.

1.18.4 Automatic trainstop at Toronto Transit Commission

The TTC fixed block signalling system controls subway train movements, including the speed of trains, with a device known as the Automatic Trainstop (Trainstop). This system has been widely used in commuter rail systems throughout North America since the 1930s to ensure compliance with stop indications. Trainstop automatically stops a train when the signal aspect and the operating rule prohibit such a movement. The system operates by mechanical engagement of a trip arm, which is attached adjacent to the field side of the rail. On each train, there is a trip valve that is connected directly to the train air brake system.

When the signal is clear, the trip arm lowers so that trains can pass at will. When the signal requires a stop (that is, red aspect) the wayside trip arm is raised to the danger position so that it engages the trip valve and activates an emergency brake application.

1.18.5 Computer-based train control on Scarborough light rail system (TTC)

The TTC Scarborough Light Rail System utilizes a computer-based train control system that has been in place since the mid-1980s. A similar system is used to operate the “Skytrain” in Vancouver, British Columbia.

The computer-based train control system on the Scarborough light rail line is a moving block train control system where wayside equipment and train-mounted equipment exchange information and commands through a continuous inductive loop wire laid in the track bed. There are on-board computers on each train and a master computer at a fixed location. There is continuous communication on the loop cable between the on-board train computers and the master computer. The on-board computer continually transmits train position and speed, computes braking distances and ensures that the train remains within the speed limits imposed by the master computer. This data exchange ensures safe train spacing, safe braking, continuous monitoring and speed control of all trains.

1.18.6 Speed control system at Toronto Transit Commission

TTC has recently installed a speed control system (SCS) on its Yonge/University/Spadina subway line. The SCS is an overlay on TTC's conventional relay logic signalling system. The main function of the SCS is to supervise and enforce permitted speed limits, restricted speeds, reduced speed zones and signal adherence. Electronic transponders are installed at track level throughout the system and yards. A train on-board controller detects the wayside transponders, determines train location and then calibrates wheel revolutions for exact positioning.

The on-board controller compares the transponder information with track and system information stored in its memory after which it calculates the location of the train and controls train speed for that area of track. The speed is displayed on the train driver's console and an audible alarm sounds if an overspeed occurs. If the train driver does not respond appropriately to an overspeed or a signal indication, the SCS engages the train brakes.

1.18.7 Train control systems at Amtrak

In May 1971, the United States National Railroad Passenger Corporation (Amtrak) was formed and Amtrak has been managing the United States rail passenger service since that time. The TSB met with Amtrak to obtain an overview of the train control systems that are currently in place on its Northeast Corridor (NEC). In the NEC, Amtrak operates a fully electrified railway using overhead catenary wires to power its locomotives. Conventional diesel motive power equipment can also operate on the same tracks provided that the equipment is also equipped with in-cab signals and ATC. Amtrak trains on the NEC are operated by a single locomotive engineer in the locomotive cab.

The NEC comprises about 430 track miles from Boston, Massachusetts, to New York City, New York, and to Washington, DC, with branches serving other cities. The NEC is the busiest passenger rail line in the United States by ridership and service frequency with over 300 trains on Amtrak–controlled segments each weekday. Presently, about 75 % of paid travellers between New York City and Washington travel by train. The NEC train traffic includes

- conventional freight trains powered by diesel locomotives operated by CSX and the Providence and Wooster railways that travel at speeds between 30 and 50 mph,

- Amtrak regional trains that travel at speeds between 110 and 135 mph,

- various commuter trains that travel at speeds up to 135 mph, and

- Amtrak Acela Express high-speed trains that travel at speeds up to 150 mph.

The following list summarizes various events that led to the development and implementation of train control systems on the NEC:

- Since 1938, passenger locomotives that operated on the NEC have been equipped with cab signals that display wayside signals in the locomotive cab to the operating crew.

- On 17 June 1947, the United States ICC ordered (Order No. 29543) that cab signals, automatic train stop or ATC be installed on any line on which train speed would exceed 79 mph.

- Since 1952, passenger locomotives were also equipped with a fully functioning ATC system. The ATC system incorporates cab signals and speed control with a penalty brake. If a train operator does not respond to the signal displayed in the cab, the system automatically applies a penalty brake application to control the train speed in accordance with the signal displayed.

- On 04 January 1987, a train collision occurred near Baltimore, Maryland, United States. While proceeding at about 108 mph (174 km/h), the Amtrak passenger train collided with a Conrail locomotive consist, which had fouled the mainline. As a result of the accident, the Amtrak locomotive engineer, a lounge car attendant and 14 passengers were fatally injured. Since 1988, and as directed by the FRA, all trains that operate on the NEC have been equipped with cab signals and ATC.

- Since 2000, in certain areas of the NEC where Amtrak's high-speed Acela trains operate, ATC has been supplemented by Amtrak's Advanced Civil Speed Enforcement System (ACSES). ACSES is a transponder-based overlay system that operates in parallel with ATC on Amtrak trains. The transponders are passive devices that require no energy source other than that of a passing train. They contain basic information and are permanently fastened between the rails of a track on top of the ties, in sets of at least 2.

- ACSES uses transponder information, data radios and train speed information to perform calculations and enforce permanent and temporary speed limits as well as positive stops at interlockings and signals displaying stop indications. ACSES was initially installed between New Haven, Connecticut, and Boston, Massachusetts (180 route miles), and on 2 sections of the NEC (about 50 route miles) between New York and Washington. Transponders are currently being installed throughout the remainder of the NEC (200 miles). It is expected that, by 2014, the entire NEC will be fully equipped with both ATC and ACSES for all Amtrak trains.

- Although Amtrak ATC and ACSES operate as independent systems, in combination, they each function as part of Amtrak's PTC system. The systems share a common aspect display unit in the cab. ATC and ACSES can continue to operate providing enforcement functions in the event that the other system fails. When operating in parallel, both systems provide speed enforcement with the more restrictive speed prevailing. In February 2010, the FRA approved the Amtrak system as a fully functioning PTC system.

1.19 Amtrak locomotive simulators

The TSB operated 2 Amtrak train simulators that were programmed for the NEC. The signal and rule system utilized by Amtrak differs slightly from the CROR and Canadian CTC. In particular, slow speed can be 20 to 30 mph while the CROR defines slow speed as 15 mph. However, the fundamentals of train control using progressive signal indications remain the same. Amtrak signal blocks Footnote 10 have been shortened to approximately 1 mile to accommodate increased train speeds and traffic volume. In comparison, the distance between controlled signal locations in the vicinity of the accident is about 3 miles.

One simulator was set up similar to an Acela cab equipped with cab signalling, ATC and ACSES. In addition to adherence to signals, ACSES also enforces speed restrictions and upcoming stops. If there is no appropriate action or response from a locomotive engineer, ACSES slows the train for a slow order and stops the train before it arrives at a stop indication. During a simulation, attempts were made to speed past a restricting signal indication and a stop indication. In both cases, ACSES prevented actions that were contrary to the signal indications displayed.

Another simulator was set up similar to the VIA 92 General Motors (GM) F40PH-2D locomotive cab. It was also equipped with cab signalling and ATC (speed enforcement and penalty brake). In the first simulation, the ATC enforced the speed in the block occupied by the train. However, the next block was not displayed or enforced. When a signal indication displayed red, the stop was enforced after the signal was passed. While the signal that displayed a stop indication could be passed, the speed approaching a stop indication was reduced so the signal was passed at a much slower speed. After the train passed the signal, the system enforced the full stop.

An operations re-enactment was conducted on the simulator that was set up similar to the VIA 92 GM F40PH-2D locomotive cab. Using existing Amtrak cab signalling, ATC, operating rules and signal aspects, a simulation was programmed with a progression of signals similar to those displayed for VIA 92’s approach to Aldershot East. The simulation demonstrated the functionality of a cab signalling system interfaced with ATC. The following events occurred in the simulation:

- the signals in advance of Aldershot Station limited the train speed within the block to 20 to 30 mph;

- after stopping at Aldershot Station, the train was limited to 20 to 30 mph upon departure (depending on aspect displayed) up to signal 334T2 just before crossover No. 5; and

- when the train passed signal 334T2, the ATC enforced a further speed reduction.

1.20 Amtrak in-cab voice recording

All Amtrak Acela locomotive cabs are equipped with in-cab voice recording interfaced with the LER. The voice recorder operates throughout the journey on a loop that records 20 minutes of in-cab activity and continually overwrites the tape.

Voice recordings are automatically saved when certain events are triggered. The recordings are saved when the locomotive sustains an impact of 3 Gs (1 G = force of gravity) Footnote 11 or more or the locomotive lists at least 20° off centre. When a triggering event occurs, the system automatically saves the last 20 minutes of recorded cab activity in the LER.

1.21 Train control systems in other countries

Various forms of ATC have been operational in other countries for decades. These systems usually include some form of ground-based system and on-board system that interconnect to provide the functionality of an ATC system. For example:

- An automatic warning system (AWS) was introduced in the United Kingdom in 1956 and has transitioned to what is known today as the train protection and warning system (TPWS).

- France, Germany and Italy have implemented full automatic train protection (ATP), which is similar to ATC, for dedicated high-speed rail lines. Europe is currently transitioning to one ATP standard called the European Rail Traffic Management System (ERTMS). ERTMS is well evolved as a result of many years of European ATP experience and development.

- Danish and Swedish railways use sophisticated ATC technologies to enforce signal compliance and speed restrictions while Tranzrail in New Zealand uses a vigilance device that sounds an alarm and stops the train if the train driver fails to respond.Footnote 12

- Some railways in other non-European countries such as Australia, India and China operate with functioning ATC systems. In particular, the high-speed railway lines in the People’s Republic of China operate using the Chinese Train Control System (CTCS), which is similar to the ERTMS.

To date, no major passenger (VIA) or freight railway (CN or CPR) in Canada has implemented any form of automatic train control.

1.22 VIA 92 locomotive and coach information

Information regarding rolling stock involved in the accident is contained in Table 3 below.

| Rolling stock | VIA no. | Builder | Model | Type | Year built |

|---|---|---|---|---|---|

| Locomotive | 6444 | GM Electro-Motive Division (EMD | F40PH-2 (GPA-30h) | Wide-nose locomotive | 1989 |

| 1st coach | 3454 | Bombardier | LRC | VIA 1 club car | 1984 |

| 2nd coach | 3354 | Bombardier | LRC | Coach | 1983 |

| 3rd coach | 3318 | Bombardier | LRC | Coach | 1980 |

| 4th coach | 3319 | Bombardier | LRC | Coach | 1980 |

| 5th coach | 3311 | Bombardier | LRC | Coach | 1979 |

1.23 VIA locomotive rebuild

VIA 6444 was manufactured in 1989 and was 1 of 53 GM F40PH-2D locomotives delivered to VIA between 1986 and 1990. This wide-nose locomotive is configured with the short hood leading. The locomotive body is fully enclosed and has internal walkways for access to the engine compartment. These 4-axle, 3000 horsepower diesel-electric locomotives were built for passenger service.

In 2007, VIA contracted CAD Industries in Montréal, Quebec, and commenced a rebuild program for the GM F40PH-2D fleet during which each locomotive was stripped down to its frame (see Photo 7) and rebuilt from top to bottom (see Photo 8). The rebuild work for VIA 6444 was completed in December 2009 and it was returned to service.

The GM F40PH-2D locomotives were rebuilt with technical upgrades for improved operating efficiencies and reliability. These upgrades included improvements to the trucks, to the locomotive motor and to the generator that powers the passenger cars. In addition, a new crashworthy LER was installed in accordance with TC–approved Railway Locomotive Inspection and Safety Rules (Locomotive Safety Rules) and the cab roof structure was modified to accommodate an air conditioner. The original fuel tanks were repaired if necessary, painted and re-installed.

The front nose section of the GM F40PH-2D locomotive contains 2 substantial collision posts to protect against frontal collision. In comparison, the roof structure and cab sides were constructed with various configurations of light gauge steel (see Photo 9). The roof frame structure consisted of a number of steel U-channels that were fabricated into a 2½-inch square tube (see see Photo 10). The wall thickness of the tube was 0.120 inch (just under 1/8 inch) while the roof sheeting was 0.135 inch thick (just over 1/8 inch). There was no significant corner post structure and no roof reinforcement.

During the rebuild, there was no structural upgrade in the area of the cab to protect against rollover or impact. This rebuild did not include the structural requirements outlined in Part II of the Locomotive Safety Rules and nor was it required. Once rebuilt, the service life of these locomotives can extend up to 40 years or longer if rebuilt again in the future. Such rebuild programs are not uncommon in the rail industry.

The rebuild did not include the installation of an in-cab voice recorder. In TSB investigation report R99T0017, the Board recommended that:

The Department of Transport, in conjunction with the railway industry, establish comprehensive national standards for locomotive data recorders that include a requirement for an on-board cab voice recording interfaced with on-board communications systems.

Transportation Safety Recommendation R03-02 (issued July 2003)

Considering that TC had implemented partial performance specifications for data collection, the Board assessed TC’s response as Satisfactory in Part. However, the Board remains concerned that the principle of voice recordings as a valuable safety tool has not been implemented.

1.24 Regulatory requirements for locomotive crashworthiness

VIA's F40PH-2D locomotives were originally built in accordance with the standard in place during the 1980s, which was Canadian Transport Commission General Order 0-21, otherwise known as the Railway Motive Power Equipment Regulations. The regulations contained no specific requirements relating to locomotive cab crashworthiness, as such standards had not yet been established. The Canadian Transport Commission was replaced by Transport Canada (Rail Safety) in the early 1990s. General Order 0-21 remained in place until 1997 when the TC–approved Locomotive Safety Rules were implemented.

1.24.1 Locomotive safety rules

The Locomotive Safety Rules established in 1997 outlined the minimum criteria for locomotive design and crashworthiness. However, nothing precluded a railway company from specifying a more robust design.

Part II, Locomotive Design Requirements, Section 10, General Design, indicates the following:

10.1The locomotive shall be designed and constructed to provide for safe operation and protection of the operating crews and property from accidents caused by functional failure of locomotives.10.2New locomotives shall be designed and constructed as a minimum in accordance with the “Association of American Railroads Manual of Standards and Recommended Practices” (S-580) or to an equivalent standard to provide for safe operation and for the protection of operating crews, and property from accidents caused by functional failure of locomotives.

In January 2006, the Locomotive Safety Rules were modified to include separate crashworthiness standards for freight and passenger locomotives. This remains unchanged in the present version of the Locomotive Safety Rules dated February 2010.

10.2 (a) Freight Locomotives

New locomotives shall be designed and constructed as a minimum in accordance with the latest revision of the “Association of American Railroads Manual of Standards and Recommended Practices” (S-580) or to an equivalent standard

[....]10.2 (b) Passenger Locomotives

New locomotives shall be designed and constructed as a minimum in accordance with the latest revision of the “American Public Transit Association” (APTA), the Association of American Railroads Manual of Standards and Recommended Practices or equivalent standard.

By reference, the applicable APTA standard is 11.APTA SS-C&S-034-99, Rev. 2, Standard for the Design and Construction of Passenger Railroad Rolling Stock.

In the United States, parts 229 and 238 of the FRA Title 49 of the Code of Federal Regulations established the final rule on locomotive crashworthiness in 2006, with most provisions taking effect 01 January 2009. Section 229.203 requires that locomotives manufactured or remanufactured in the United States on or after 01 January 2009 must meet crashworthiness standards. By reference, the FRA final rule also incorporates the latest revision of AAR Standard S-580.

1.24.2 Locomotive crashworthiness standards – Association of American Railroads Manual of Standards and Recommended Practices Standard S-580

AAR Standard S-580 provides requirements applicable to all new road-type locomotives, except for passenger-occupied vehicles, manufactured after 31 December 2008 (from 01 January 2009 on) for use on standard gauge track on North American railroads in revenue freight service or in commuter/passenger service. A summary of locomotives operated by major Canadian passenger and freight railways built prior to 01 January 2009 is provided in Table 4 below.

| Railway | Number of road locomotives | Number built prior to 2009 | Percentage built prior to 2009 |

|---|---|---|---|

| VIA | 74 | 74 | 100 |

| CN | 1393 (North America) | 1208 | 87 |

| CPR | 1539 (North America) | 1448 | 94 |

The primary purpose of AAR Standard S-580 is to minimize the potential for injuries and fatalities to train crews and others involved in the transportation of freight and passengers. This standard provides design requirements for locomotives with improved crashworthiness features. The design requirements were developed as enhancements to the original AAR Standard S-580 (1989).

Locomotives used in freight service and VIA passenger service in Canada are primarily of 2 designs. They are either a wide-nose locomotive design (North American cab) or narrow-nose locomotive design. A wide-nose locomotive has a short hood leading that spans the full width of the locomotive while a narrow-nose locomotive has a short hood leading that spans substantially less than the full width of the locomotive.

AAR Standard S-580 specifies that wide-nose locomotives must have substantial collision posts at the front of the locomotive to protect against frontal collisions. It states in part that

- Each locomotive must be equipped with at least two collision posts or equivalent structures that are located as follows:

- at the approximate 1/3 points across the width of the locomotive

- in their entirety forward of the seating position of any crew person

- must extend in height to a distance 24 in. above the finished cab floor

Each collision post must be continuously attached/welded to the front skin and roof of the short hood

Each collision post must withstand the following loads without exceeding the ultimate strength of the posts and their attachments to the underframe:

- A 750,000-lb load applied over the bottom 10 % of the overall height of the collision post at the base […], at any angle in the horizontal plane in the range of ±15° of the longitudinal axis of the locomotive

- A 500,000-lb load applied over an area, the width of the post structure and the height of 10 % of the overall height of the post on each collision post, centered at a height 30 in. above the top of the underframe […], at any angle in the horizontal plane in the range of ±15° of the longitudinal axis of the locomotive.

Each main diesel fuel tank […] must meet the requirements of MSRP [Manual of Standards and Recommended Practices] Standard S-5506, “Performance Requirements for Diesel Electric Locomotive Fuel Tanks,” latest revision.

The short hood must be capable of supporting a longitudinal load of 400,000 lb. applied to the front of the short hood in the upper corner over an area that is 12 in. wide starting 30 in. above the top of the deck and extending to the nose cab roof sheet without exceeding ultimate strength [....]

[a truck attachment that secures each truck to the frame of the locomotive.] Attachment of each truck to the frame must withstand an equivalent ultimate shear value of 250,000 lb from the longitudinal to lateral, inclusive.

Cab corner posts and rollover protection are not required for wide-nose locomotives.

Narrow-nose locomotives must meet the same requirements as wide-nose locomotives with the exception of the following:

- [Operator's cab] corner posts must be provided at all corners of the cab structure.

Each corner post, supporting structure, and intervening connection must resist the following horizontal loads individually applied in the direction stated:

- Minimum of 300,000 lb applied at a point even with the top of the underframe without exceeding the ultimate strength of the post. This load must be applied at any angle in the horizontal plane in the range of ±8° from the longitudinal axis of the locomotive.