Railway Investigation Report R94T0357

Fire

VIA Rail Canada Inc.

Passenger train no. 66

Struck a piece of rail placed on the track

Mile 242.07

CN North America Kingston Subdivision

Brighton, Ontario

20 November 1994

The Transportation Safety Board of Canada (TSB) investigated this occurrence for the purpose of advancing transportation safety. It is not the function of the Board to assign fault or determine civil or criminal liability. This report is not created for use in the context of legal, disciplinary or other proceedings. See Ownership and use of content.

-

Table of contents

Summary

On 20 November 1994, at approximately 1820 eastern standard time, VIA Rail Canada Inc. (VIA) train No. 66 (VIA 66), travelling eastward at approximately 96 mph, struck a piece of rail intentionally placed on the track at Mile 242.07 of the CN North America (CN) Kingston Subdivision, in Brighton, Ontario. A fire erupted and the trailing portion of the locomotive and the first two passenger cars behind the locomotive became engulfed in flames. Forty-six of the 385 passengers were injured, most while exiting the train in life- threatening conditions.

The Board determined that the piece of rail punctured a locomotive fuel tank and severed electrical power cables creating electrical arcing which ignited the leaking fuel. The design and configuration of the locomotive components did not protect the exposed fuel tank or power cables nor mitigate the volume of fuel loss. The emergency exit features of the passenger cars did not provide an acceptable level of safety. The shape of the locomotive pilot was such that it did not tend to deflect objects away from the path of the train.

1.0 Factual information

1.1 The occurrence

At approximately 18201 on 20 November 1994, eastward VIA Rail Canada Inc. (VIA) train No. 66 (VIA 66), carrying 385 passengers, approached the Ontario Street public crossing at Mile 242.07 of the CN North America (CN) Kingston Subdivision, in Brighton, Ontario, at approximately 96 mph. The two locomotive engineers observed a short piece of rail lying on the north rail, just west of the crossing. The piece of rail had been deliberately placed on the tracks by two local residents approximately 10 minutes before the arrival of the train.

The Ontario Provincial Police (OPP) conducted an investigation to identify those responsible for placing the piece of rail on the track. Two individuals were apprehended, charged and later convicted of mischief endangering human life, an offence pursuant to the Criminal Code of Canada.

The first locomotive engineer, who was at the controls, placed the throttle in idle just before striking the piece of rail. The piece of rail was then heard to contact the underside of the locomotive. Almost immediately, the locomotive engineers observed fire coming from the rear of the locomotive.

The first locomotive engineer then applied the train brakes. The second locomotive engineer made an emergency radio broadcast to alert other trains in the area to their situation. He then notified the CN rail traffic controller (RTC) in Toronto, Ontario, of the emergency, to obtain protection for their train and request assistance.

The locomotive-supplied electrical power to the train ceased just after the impact, resulting in the loss of normal on-train lights and the activation of the emergency lighting. The forward portion of the train was quickly engulfed in flames, and smoke entered the club car which was marshalled immediately behind the lead locomotive.

The interiors of the first two cars were illuminated by the flames. The effectiveness of the emergency lights was lost to the smoke. Passengers in the first two cars either did not notice the emergency lighting or indicated that it did not last long.

Passengers and VIA employees in the club car reacted immediately. An on-board service (OBS) employee shouted for people to move to the rear of the car. The first passengers to move to the rear, however, were unable to open the door leading to the following car. Panic ensued. Windows began to melt and shatter from the heat. Flames and smoke filled the car. Passengers had their hair and eyebrows singed by the fire. Many felt that they would not survive.

Passengers and OBS employees began breaking windows with their feet and fists. Some dropped to the floor of the car to try to avoid the smoke which had made breathing difficult. An OBS employee located forward in the car shouted that she could open the door and made her way over and around passengers, who were crowded in the aisle, to the door which she was able to open. By this time, passengers were exiting through the broken windows, some while the train was still moving. One passenger lowered his child out a window of the still moving train before he himself jumped out.

Passengers from the club car moved into the following car once the three doors were opened.

The second car was subjected to the same fire and heat. A window had shattered and smoke had filled the car. As the train stopped, passengers in the second car moved into the aisle and, as in the club car, many fell to the floor to avoid the smoke. One passenger had a flashlight which helped locate an emergency hammer. That passenger's efforts to break an emergency window with the hammer proved to be unsuccessful. Windows were, however, punched and kicked out and many used these openings as a way to escape. Passengers who had moved to the rear of the second car were confronted with a fire between the second and third cars. A VIA employee moved to the front of the second car and, after initial difficulty, managed to open and lower the south-side stairway. He also managed to break an emergency window with a break-out hammer. Another VIA employee was then able to open the north stairway from the outside of the train. Many passengers from the first two cars exited from these lowered stairways.

The remaining cars were little affected by the fire and smoke. Passengers remained in their seats in response to the orders of the VIA employees in these cars. Once the stairways were all lowered, these passengers were evacuated in an orderly fashion.

VIA employees caught people as they jumped from the windows of the first two cars. They also gave directions to passengers milling about on the right-of-way.

First-aid supplies were taken from the undamaged cars and distributed to the injured and those administering first aid.

Attempts were made to start the trailing locomotive which had inexplicably shut down. It was intended to split the train between the third and fourth cars, move the rear portion of the train westward and use the locomotive power to provide shelter and warmth for the displaced and injured passengers. However, the trailing locomotive would not start.

The train came to a stop at approximately Mile 240.07, about 10,600 feet east of the Ontario Street crossing. Once the train stopped, the intense fire, fanned by the motion of the train, subsided but the locomotive and first two cars continued to burn. The burning train provided illumination for those administering first aid. It also eased the movement of passengers and employees on the right-of-way.

Mile 240.07 is in a rural location. The nearest residence is approximately 1/4 mile north of the right-of-way. A forested area, situated between the burning train and the residence, contained marshy areas with water approximately four to five feet deep. When it was determined that a passenger train was ablaze, the family from the residence hurried to render assistance. A front-end loader was used to clear a pathway from the railway right-of-way to the home. Family members, equipped with flashlights, directed ambulatory passengers to their home where many were given shelter and, in some cases, clothing. Passengers waited at the residence until they were transported to hospitals or to the nearby Brighton High School, where the uninjured passengers were grouped to await transportation to their final destinations.

Passengers requiring assistance to move, including six physically challenged members of a wheelchair basketball team and those incapacitated by their injuries, were transported westward by a CN Hi-rail vehicle to awaiting ambulances at the Prince Edward Street crossing at Mile 241.59.

1.2 Injuries

Many passengers who exited through the window openings sustained cuts, burns and abrasions. Some passengers also incurred sprains, bruising and broken bones jumping from the windows. Others were injured while stepping from the vestibule stairs into the darkness. Several passengers had removed their footwear before the occurrence and, while attempting to exit, burned their feet on the hot floors of the first two cars.

Some passengers sustained injuries when moving through the forested and swampy area north of the scene or through the deep ditch to the Canadian Pacific Limited (CP) track to the south.

In all, 15 passengers were seriously injured and 31 passengers received minor injuries.

1.3 Damage

The fire destroyed the engine compartment of the lead locomotive. The club car was completely destroyed and the coach next to the club car was extensively damaged. The four other coaches and the trailing locomotive sustained slight damage.

1.4 Other damage

The intense heat from the fire caused rail distortion. Two sections of rail were replaced at the location where the locomotive and first car stopped. A crossover and several ties between Mile 242.07 and Mile 241.59 sustained minor damage.

1.5 Personnel information

The operating crew included two locomotive engineers in the lead locomotive, a conductor in the second car behind the locomotive, and an assistant conductor in the trailing locomotive. They were qualified for their respective positions and met fitness and rest standards established to ensure the safe operation of trains.

Seven on-duty OBS employees were positioned throughout the train. An off-duty OBS employee was also on the train.

1.6 Method of train control

Traffic on the Kingston Subdivision in the area of the occurrence is governed by the Centralized Traffic Control (CTC) system authorized by the Canadian Rail Operating Rules (CROR) and supervised by an RTC located in Toronto.

The maximum authorized passenger train speed at the occurrence site was 100 mph.

1.7 Train information

VIA 66 was an eastward passenger train operating daily, except Saturday, between Toronto and Montreal.

It consisted of Light, Rapid, Comfortable (LRC) equipment marshalled from front to rear as follows:

- Locomotive 6920 - leading

- Club car 3457 - vestibule doors forward

- Coach 3349 - vestibule doors forward

- Coach 3302 - vestibule doors forward

- Coach 3303 - vestibule doors forward

- Coach 3336 - vestibule doors trailing

- Coach 3308 - vestibule doors trailing

- Locomotive 6917 - trailing in reverse

1.8 Weather

It was clear with a light south-west wind. The temperature was four degrees Celsius.

1.9 Recorded information

Data were extracted from event recorders on the lead and trailing locomotives. Event recorder information, obtained from the lead locomotive, indicates that, at a recorded time of 1810:18.7, train whistling ceased and the throttle was reduced from position No. 4 to idle, while the train was travelling at a recorded speed of 96 mph. Within two seconds, a full service brake application was shown, as indicated by a recorded brake pipe pressure reduction. At a recorded time of 1810:35.6, while the train was travelling at a recorded speed of 88 mph, remaining brake pipe pressure was lost and a sanding indication was shown. A momentary brake bail was indicated at a recorded time of 1810:59.9. Train velocity was first recorded as 0 mph at a recorded time of 1811:39.3.

The event recorder information obtained from the trailing locomotive was similar to that obtained from the lead locomotive except that the event recorder clock in the trailing locomotive was approximately one minute behind the event recorder clock in the lead locomotive. For example, the first time that the speed indicated 0 mph was at a recorded time of 1812:36.6 for the trailing locomotive rather than 1811:39.3 for the lead locomotive.

In both cases, the recorded train speed decreased in a linear fashion to a point after which it decreased at a much faster rate. In the case of the lead locomotive event recorder data, the recorded speed dropped from 39 mph to 0 mph in about two seconds and, in the case of the trailing locomotive, the recorded speed dropped from 32 mph to 0 mph in about two seconds (see Figure 2).

A computer simulation indicated that, under ideal conditions, a train with a similar consist, operating at 96 mph on tangent level track, should, when braked in a fashion identical to VIA 66, stop in 38 seconds in a distance of approximately 3,000 feet with a relatively fixed rate of deceleration.

1.10 Occurrence site information

1.10.1 General

At Mile 240.07, the subdivision consisted of two main tracks running approximately south-west to north-east. Storage tracks ran parallel to both main tracks. The single main track of the CP Belleville Subdivision was approximately 75 feet south of and parallel to the CN main tracks. The two railways are separated by a swampy ditch approximately 15 to 20 feet deep with steep banks and considerable underbrush.

Approximately 20 feet west of the Ontario Street crossing, intermittent gouge marks on the rails and ties were observed. Gouge marks were also evident on the asphalt crossing surface. The asphalt at the Prince Edward Street crossing (Mile 241.59) was similarly marked.

There were indications of grass fires along the right-of-way between Ontario Street and Prince Edward Street, a distance of approximately 2,500 feet. A metal signal bungalow, located approximately 12 feet south of the south main track, midway between the two crossings, was seared, blackened and coated with diesel fuel. Diesel fuel was also evident on the roadbed from the Ontario Street crossing to where the train came to a stop.

Shards of broken glass, melted glass and solidified puddles of molten metal were observed on the roadbed for a distance of approximately 1,300 feet behind the stopped train.

A piece of rail, measuring approximately 46 inches (1.2 metres) in length and weighing about 168 pounds (75.6 kg), was found 48 feet (14.4 metres) south of the south main track on the crossing sidewalk at Prince Edward Street. It displayed gouges, scuff marks and was covered with diesel fuel.

1.10.2 Post-accident equipment condition

1.10.2.1 Lead locomotive

The paint on the bottom left portion of the pilot appeared to have been removed as a result of a combination of scoring and flaking because of plastic deformation of the metal surface consistent with mechanical impact damage. There was no oxidation or corrosion on the bare metal surface.

Major mechanical impact damage was inflicted on the bottom left side (north side) of the locomotive just forward of the mid-section. Fire damage was evident on the underside and sides of the last half of the locomotive.

The electric power cables, providing power to the traction motors, the operating compartment and coaches, were routed along the central belly of the locomotive in two bundles. To the rear, all sheaths covering the bundles were burned out. Three of the five cables in the bundle on the left side of the unit were severed. There was fusion of the wire strands along with pitting and formation of globules of metal on the ends of adjacent broken wire strands of the severed cables.

The break in the bundle of cables was situated immediately adjacent to a broken and bent piece of metal strapping and a hole in the left-side locomotive fuel tank, and near a ruptured crossover fuel feed from the right-side tank.

The internal surfaces and edges of this hole and some exterior metal surfaces adjacent to it were coated with diesel fuel. The hole in the fuel tank was rectangular in shape, approximately 9 inches wide at its base, 18 inches in length, and approximately 6 inches in width at the narrow end. The break in the strapping and the hole in the fuel tank penetrated approximately 1/2 inch (1.3 cm) of metal (the combined thickness of the strapping and the fuel tank).

The penetrating object left an impact mark on a metal surface inside the fuel tank. The height at which the indentation had been made above the top of the railway ties was approximately 46 inches (1.2 metres). Most of the impact mark exhibited a relatively shiny surface which appeared to have been created as a result of the surface being deformed as well as abraded by a metal object. The outline of the impact mark resembled the cross-section view of a piece of rail. The silhouette of the head (top), web (vertical member), and base (horizontal portion) of a piece of rail was evident on the mark.

1.10.2.2 Club car

The club car was exposed to sufficient heat to deform its primary supporting structure, and a pronounced sag in the frame between the front and rear trucks was evident. Most of the metal exterior shell of the car below the window level was intact. However, several metal panels below the window level were burned through, particularly on the north side near the locomotive. The majority of the metal skin of the roof on the right side was burned away or collapsed into the interior of the car, leaving portions of the right-side wall still standing. Part of the roof skin was still present on the left side of the car.

The interior of the car, including the moulded plastic inner walls and ceiling, was completely consumed by fire, leaving the 54 steel seat frames.

1.10.2.3 Coach 3349

The leading end of coach 3349, including the interior of the vestibule, sustained extensive melting and distortion. The interior of the car sustained minor heat damage, but extensive smoke and water damage. Several windows were broken.

1.11 LRC locomotives

The LRC locomotives were manufactured by Bombardier in 1980. The two underslung fuel tanks, which had a metal thickness of approximately 1/4 inch (6.3 mm), were on either side of the locomotive and had a combined capacity of 1,666 imperial gallons (7,597 litres). The bottoms of the fuel tanks were approximately 6 1/2 inches (16.25 cm) above the top of the rail. Neither the fuel tanks nor the three cross-feed lines between them were shielded against impacts from foreign objects. Damage to the cross-feeds or the lower tank bodies resulted in the entire diesel fuel load draining to the ground. Electrical cables were suspended beneath the fuel tanks and were not protected against impact from foreign objects. The exterior of the locomotives was fabricated of aluminum alloy.

The locomotive pilot was made of a 1/2-inch (1.3-cm) thick steel plate extending straight down across the front of the locomotive and was maintained to ride between 3 inches (7.5 cm) and 6 inches (15 cm) above the rail head (the Association of American Railroads' standard).

A second plate, bolted to the pilot, reinforced the bottom edge and allowed for height adjustment at regular maintenance intervals if required. The pilot had a slight curvature to conform to the form of the locomotive but otherwise was blunt and at right angles to the track.

A locomotive pilot is intended to clear foreign objects forward and sideways from in front of the locomotive.

1.12 LRC passenger cars

1.12.1 General

There were two types of passenger cars on VIA 66: one LRC club car and five LRC coaches. Plan and profile drawings of both types of equipment are found in Figures 8 and 9 respectively. The club car could seat 54 passengers, and the coaches, 72 each.

1.12.2 LRC corridor door

Each car was equipped with three corridor doors; two at the "B" end and one at the "A" end. These doors opened manually or automatically. The automatic door was operated manually when power was lost. The manual door, when pushed fully open, was held open for approximately 10 seconds by an air-activated solenoid, before reverting to the closed position. Each corridor door was equipped with a glass window measuring 64 inches (160 cm) high, 10 inches (25 cm) wide and 1/4 inch (6.3 mm) thick.

Manual corridor doors were designed to be opened by inserting finger tips into an indented slot, approximately 4 feet (1.2 metres) above the floor and then by exerting horizontal pressure to slide the door into the bulkhead wall.

Automatic corridor doors were equipped with two activation pads, one approximately 4 feet (1.2 metres) above the floor to be touched by a hand, for hand operation, and the other, about 1 foot (0.3 metres) above the floor to be touched by a foot, for foot operation. Either design procedure results in the door sliding into the bulkhead wall.

Club car 3457 was equipped with manual corridor doors and the coaches had automatic corridor doors. It should be noted that, in VIA's LRC fleet of 100 cars, all 25 club cars were equipped with manual corridor doors. Twenty-five of the coaches had manual corridor doors and the remaining 50 were equipped with automatic corridor doors. The intermixing of manual and automatic corridor doors in a train was noted as causing confusion because of the different procedures required for their operation.

There was no written information posted that pertained to the operation of either type of door. However, there were pictograms about 5 feet (1.5 metres) above the floor displaying hand and foot operation for automatic doors. There were no pictograms displaying the process to open the manual doors. Neither type of door had instructions or pictograms to explain or depict how to open the corridor doors in an emergency when emergency and locomotive power were lost.

In the event that both locomotive power and emergency power were lost (as in this case), the corridor doors were designed to be forced open. Pull tests conducted on a door by the TSB Engineering Laboratory (report LP 182/64) indicated that the average static horizontal (sideways) force necessary to open the door manually was 37 pounds. The door remained in an "as left" position once the horizontal force was discontinued.

Tests conducted shortly after the occurrence at VIA's Toronto Maintenance Centre (TMC) on three passenger cars with automatic doors that had been made ready for departure revealed that two of the nine doors were defective.

One of these doors had a defective closing release sensor which applied compressive forces of approximately 76 pounds pressure on any object between the door and the door frame. Theoretically, this force could have been applied to a person in the doorway—a force that would remain until the power to the door was turned off.

The other door had a non-functional lower opening pad; however, the upper opening pad on the door was functional. In a smoke-filled car, the lower pad may be the only pad visible to passengers.

1.12.3 LRC vestibule door

The vestibule end of each passenger car was equipped with two exterior doors (vestibule doors) and stairs with four steps allowing entry or exit from either side of the car.

The vestibule doors were 75 inches (1.9 metres) by 38 inches (0.95 metres) and slid longitudinally into the side wall of the car. They were designed to be operated electrically (locomotive power or emergency power) or manually from either inside or outside of the car.

Power operation was performed by inserting a key into an overhead slot in the vestibule ceiling inside the car, or by inserting a key into a slot under a flap beside the door, outside the car. The keys were held by all VIA employees on the train and were not available to passengers.

Manual operation of the vestibule door was accomplished by pulling down on a "T" handle located in the 79- inch (2-metre) high ceiling inside the vestibule. Not all passengers could reach this handle. The TSB Engineering Laboratory determined that an average force of 98 pounds was required to move this handle which disengages the electrically operated door mechanism. The door could then be pushed longitudinally into the side wall of the car, although care had to be taken to prevent hand injury because of the design of the system. The same procedure was found to be possible from the outside of the car, by pulling the "T" handle which was located under a hinged flap beside the door. Both exterior hinged flaps are covered by the exterior colour scheme and not identified as to their function and operation. Although not measured, the pull required to release the door from the outside was minimal.

A small pictogram (5 inches by 3 inches or 12.5 cm by 7.5 cm) was located in the vestibule illustrating the use of the interior "T" handle and the operational direction of the door. However, identical pictograms were displayed on both sides of the car. This resulted in an incorrect illustration of door movement direction being displayed on one of the doors. There were no instructions inside or outside to indicate how to open the vestibule doors from the outside.

Once the vestibule doors were either electrically or manually opened, the vestibule steps could be operated manually by depressing a latch located over the step area inside the vestibule. When the latch was released, a spring-loaded mechanism was activated which partially raised the platform over the stairwell. The stairs could then be lowered through a series of interconnected levers and were locked into the down/open position by securing the platform to a wall-mounted latch. The last step was approximately 12 inches (30 cm) from the rail head and, depending on the distribution of the ballast, up to 30 inches (75 cm) from ground level.

1.12.4 LRC car windows

There were 20 windows, 10 on each side of the club car and the coaches. Each window, approximately 32 inches (0.8 metres) above the floor at the bottom edge, measured 30 1/2 inches (0.76 metres) high by 56 3/4 inches (1.4 metres) wide and consisted of two 1/4-inch (6.3-mm) thick panes of glass, separated by a 2 1/2-inch (6.25-cm) space filled with an inert gas. Four of the 20 windows, two on each side, were identified as emergency exits. A small hammer, to be used for breaking an emergency window, was encased in a sealed container over each emergency exit window.

The four emergency windows were equipped with tempered glass. Tempered glass is resistant to mechanical breakage, as the manufacturing process creates compressive residual stresses on the outside surfaces of the pane. There are residual tensile stresses in the core to create a shattering effect once the outer compressive forces have been released.

In order for breakage to occur, a considerable and sharp impact load must be applied to the glass to overcome the residual compressive stresses on the glass surface. As well, the impact must be such that it produces a crack of sufficient depth that it penetrates the outer compressive skin into the tensile core of the glass pane. If this condition is met, the crack then becomes self-propagating. Tempered glass failure is usually characterized by the pane shattering into many small cube-like blocks of glass. However, if failure cannot be properly initiated, the same tempered glass window poses a significant mechanical breakage-resistant barrier. In order to use the emergency windows, two panes must be successfully broken.

The 16 regular windows were equipped with a laminated safety glass inner and outer pane. These windows could easily be broken, but the laminate layer would contain and hold the pieces in place. They could be punctured and broken away, but sharp and possibly pointed shards were retained in the gasket area. Shards did, in fact, cut many of the passengers although an effort was made, by those breaking the windows, to clear the glass from the gasket areas.

1.12.5 LRC emergency lighting and power

Emergency battery power of 60 volts direct current (DC) was designed to activate automatically when the normal power supplied by the locomotive was cut out.

The batteries (two banks of five 12-volt batteries) were contained in compartments under each passenger car. They supplied power to emergency lights located under aisle seats on one side of the car, and to overhead lights located in the galley, vestibule and washroom areas. The design standard stipulated that the batteries maintain emergency lighting for two hours at 20 degrees Celsius.

LRC passenger equipment was left at maintenance centres with emergency power activated when locomotives were disconnected. In order to prevent the batteries from discharging and freezing, emergency power was automatically shut off when the charge level dropped to 55 volts.

On 10 December 1994, the length of emergency lighting duration in two LRC cars, released for service at the Ottawa Station, was measured. In one car, the emergency lighting lasted for 10 minutes and, in the other, it remained operational for one hour. At the time of testing, the temperature was zero degrees Celsius.

At the time of the occurrence, there was no schedule in effect for replacing batteries; they were only replaced when they failed to function.

There was no exterior emergency lighting to provide illumination for passengers detraining from the equipment into darkness nor was there any emergency portable lighting (flashlights), other than that carried by VIA employees, available to assist passengers in the event of an emergency. The emergency features, such as pictograms, signage, emergency break-out hammers, exit windows and manual vestibule door handles, were not lit.

The OBS employees were each equipped with pocket-size pen-light flashlights. The operating crew each carried a standard two-battery flashlight. The pen-light flashlights were particularly ineffective; neither type provided adequate lighting in the circumstances of this occurrence.

1.12.6 LRC emergency equipment/supplies

Emergency equipment in each LRC passenger car included a basic first-aid kit, fire extinguisher, oxygen equipment, axe and sledge hammer.

There was a "multi-trauma" first-aid kit required on LRC club cars which was intended for the stabilization of multiple injuries to one person or for multiple casualties.

First-aid equipment was a requirement on all trains for use in medical emergencies in accordance with On Board Trains Occupational Safety and Health Regulations, Part II of the Canada Labour Code, dated 26 March 1987.

Although the first-aid kits were apparently complete, there were no procedures in place requiring VIA personnel to examine them on a regular basis to ensure that they were fully equipped.

Passengers, including a doctor who attended to injured passengers on the night of the occurrence, stated that the first-aid kits were inadequate. The quantity of bandages, dressing, and tapes did not meet needs. It was also noted that the scissors were dull and flimsy and unable to cut bandages.

Mandatory medical oxygen equipment on passenger cars consisted of a federal government-approved cylinder (3AL2015) with pressures ranging from 1,800 to 2,200 pounds per square inch (psi) and included valving, hoses and a face mask.

Oxygen cylinders examined in a number of LRC coaches, as part of this investigation, were not completely charged nor tested in accordance with the standards of the Canadian Government Specification Board. In one instance, the oxygen cylinder retest card had not been updated for 14 years.

It was also observed that the colour of the outer container was not standard. The cylinders were in both black and white containers in the same train consist. In addition, the cylinders in the white boxes were identified by a green cross label (indicating first aid) and the black container had no markings to indicate its contents.

It could not be determined if there had been an oxygen kit on the club car as the car and contents were destroyed. However, there was an oxygen kit on the first coach behind the club car.

1.12.7 LRC smergency sxit information

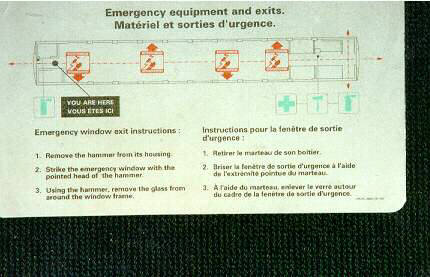

Emergency exit information was provided to passengers on two placards measuring 9 3/4 inches (24.4 cm) by 5 3/4 inches (14.4 cm). There was one placard on the wall of the galley at the "B" end of each car, and one at the "A" end of each car, near the washrooms. The pictograms on the placards identified emergency windows and included instructions on how to use the emergency hammer. The printing concerning the emergency exits was small and could be difficult to read for some passengers, particularly in the dark and when smoke was present.

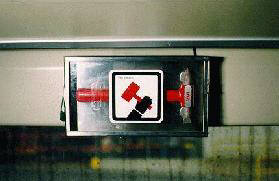

Two pictograms were displayed on each emergency exit window. Each illustrated a hand holding a hammer and the words "emergency exit". The hammer depicted (see Figure 12b) bore no resemblance in size or design to the actual hammer provided.

1.12.8 LRC emergency break-out hammer

It was intended that passengers use the LRC emergency break-out hammers to break the tempered emergency window glass to exit the car when exit through the vestibule doors was not possible. Although one window was broken by blows from a break-out hammer, all other attempts were unsuccessful.

A break-out hammer weighed approximately 10 ounces (0.28 kg) and was 6 5/8 inches (16.6 cm) long. The head of the hammer measured approximately 3 1/4 inches (8.1 cm) in length and 3/4 inch (1.9 cm) in diameter. The handle was about 5 3/4 inches (14.4 cm) in length and between 5/8 inch (1.6 cm) and 13/16 inch (2 cm) thick. The hammer head had two distinct striking ends: one was pointed and the other had a blade-like configuration.

The TSB Engineering Laboratory energy dispersive X-ray spectrometric analysis of the hammers indicated that they had been fabricated from a stainless steel alloy containing chromium, nickel and molybdenum.

A quantitative analysis showed a composition within the range of a cast CF-8M type alloy, consistent in microstructure with reference structures shown in the American Society of Metals (ASM) Handbook, Volume 7, Atlas of Microstructures of Industrial Alloys. The mean section hardness was in the Rockwell Hardness "B" 70s range. The alloy appeared to be in the as-cast heat-treat condition.

Written instructions on the placard at each end of the car (see Figure 12) indicated that the pointed end of the hammer should be used to strike the window. In this respect, no written instructions were on the emergency window itself. The intended use of the blade-like surface of the hammer was not clear.

Tests conducted by the TSB Engineering Laboratory on two emergency windows in coach 3302 demonstrated that the emergency exit windows could not be broken with the hammers provided when struck with force by an adult male. The pointed ends of the test hammers became blunt upon striking the glass. The windows were, however, easily broken when struck with a spring-loaded metal centre punch with a Rockwell C hardness of approximately 38.

1.12.9 LRC public address system

The public address (PA) system on LRC cars was designed to provide communication throughout the train, or within each individual car, while the train was either moving or stationary, with normal electrical power provided by the locomotive.

The PA system did not function on emergency power and there was no auxiliary method such as a megaphone on board the train that could be used to instruct the passengers to safety, during an emergency situation, when the normal power supply failed.

1.12.10 LRC flammability of interior coach components

There were no government regulations pertaining to the flammability, smoke and toxic gas emissions for materials used in the construction of LRC passenger cars. Information provided by VIA indicated that, by December 1993, all LRC cars had been refurbished in accordance with updated and more stringent VIA specifications. This included replacement upholstery fabric, window masks, baggage rack doors, moulding, floor and wall carpet, flexible cellular materials and seat cushions.

1.12.11 LRC ventilation system

The four LRC car fresh-air intakes were installed near the roof line on the ends of each car side. They were to supply air to a plenum running the length of the car ceiling. Outside air intake was controlled by a manually operated sheet metal flapper valve. The valves could be set for either winter or summer operation. During winter operation, the valve was in the "near closed" position, allowing little fresh air into the cars. Blower motors, to circulate the fresh air and air from within the coaches, operated on locomotive-supplied power. The controls for the circulation system were located in the vestibule area. VIA emergency procedures required that the circulation system be shut down when fire occurs.

1.13 Emergency response

1.13.1 Conductor

The conductor, who was in charge of the train and situated in coach 3349 (second car from the lead locomotive), observed the flames outside the coach windows at about the same time as the train brakes applied and the emergency lighting activated. He contacted the locomotive engineer by train radio to obtain a status report and to ensure that their train would be protected after it stopped. He was advised that the RTC had already been made aware of the situation and that protection was being provided against trains on the adjacent main track.

Proceeding forward as the train slowed and stopped, the conductor initially had difficulty getting the south- side vestibule door open on the first coach. By the time he got the door open, panic had set in among some of the passengers, as the coach was starting to fill with smoke and fumes.

In order to help alleviate the smoke problem, the conductor successfully used an emergency break-out hammer to break an inner emergency window pane and then used his feet to break the outer pane. He also broke a non-emergency exit window in the coach. Passengers followed the conductor's lead, using their feet, fists and available objects to break more windows. Moments later, the vestibule door on the north side was manually opened by an OBS employee from the outside, after which he and the conductor assisted passengers to detrain.

1.13.2 Assistant conductor

The assistant conductor was at the rear of the train when he first saw the fire. He hurried forward with a fire extinguisher to help put out the fire. However, when he realized the magnitude of the situation, he discarded the fire extinguisher and assisted with the evacuation of the passengers by opening vestibule doors on the four rear coaches behind coach 3349. He had no problems in opening these doors.

1.13.3 Locomotive engineers

The two locomotive engineers saw the piece of rail with one end lying on the north rail and the other end angled down onto the ties between the two rails just before it was struck. Both stated that objects are frequently struck on the track but, unlike this time, are normally cleared away by the pilot on the front of the locomotive.

Shortly after the rail was struck, and while the train was decelerating, the second locomotive engineer conducted the required general emergency radio broadcast and contacted the RTC. He informed him of the fire on their train and asked for, and received, protection against trains on the adjacent north main track. He also contacted westward VIA 45 which was closely approaching on the north main track, and was informed by the crew members on that train that they had overheard the emergency radio broadcast and were stopped east of the occurrence site.

When VIA 66 stopped, both locomotive engineers provided flag protection on the nearby CP Belleville Subdivision main track. They were concerned for the safety of their passengers who had congregated on the CP track. However, the CP RTC had been informed of the occurrence by the CN RTC just after it happened and had stopped CP trains from entering the area.

The first locomotive engineer was of the opinion that the wheels of the lead locomotive and the cars were sliding on the track after the train brakes were applied.

1.13.4 OBS personnel

1.13.4.1 OBS personnel in club car 3457

Two OBS employees were on duty in the club car. When the fire started, one of the employees was leaving the galley at the end of the car next to the locomotive and the other was in the middle of the car. The employee at the end of the car shouted to the passengers to go to the rear, thinking that there was a fire on the locomotive. When the passengers pushed against the manually operated corridor door, it could not be opened. Panic ensued.

The OBS employee in the middle of the car shouted to the passengers to stand back as she knew how to open the door. The passengers backed away from the door and it was then opened. The two OBS employees then assisted with the evacuation of the passengers into the next car (coach 3349).

1.13.4.2 OBS personnel in coach 3349

When the train came to a stop, the OBS employee in coach 3349 manually opened the north-side vestibule door from the outside and then assisted in the evacuation of the passengers in coach 3349, and passengers coming from the club car. Exiting was difficult because of the convergence of the passengers from two cars trying to exit the train at the same time through one vestibule door.

1.13.4.3 OBS personnel in other coaches

OBS employees located in the trailing four coaches assisted in the evacuation of passengers when required.

They had no problems in opening the doors in the four rear coaches.

1.13.4.4 Police

OPP officers from Brighton, assisted by personnel from nearby detachments, were quickly on the scene and co-ordinated all emergency activities. They were assisted by CN railway police.

1.13.4.5 Fire-fighters

The CN RTC requested assistance from the Brighton Volunteer Fire Department, and the Brighton Fire Chief immediately requested assistance from the Murray Township fire department. A total of 17 fire-fighters, from both departments, responded. Some were at the scene within five minutes of the notification. The fire was so intense that it could not be extinguished with water and it was necessary for fire-fighters to use foam to bring it under control.

The fire on the train as well as several grass fires along the right-of-way were extinguished at approximately 2100, about 2 1/2 hours after they had begun.

The fire-fighters were assisted to the site with their equipment by a nearby resident with his front-end loader, as extreme difficulty was encountered moving through the swampy terrain.

1.13.4.6 Ambulances

Thirteen ambulances transported 37 passengers to hospitals in Cobourg, Trenton and Belleville. Five other ambulances and one helicopter were also placed on standby.

1.13.4.7 Other emergency responders

The area was patrolled by a Canadian Armed Forces helicopter from the nearby Trenton air base. Air base personnel also assisted OPP officers on the ground, checking to ensure that no passengers were lost attempting to leave the area.

1.14 Safety concerns expressed

1.14.1 VIA operating crew members

The VIA train crew members expressed the following concerns:

- The hammers were inadequate to break emergency exit windows.

- Intermixing of manual and automatic power-operated doors was confusing and pictograms detailing their operation were inadequate.

- There was no emergency portable lighting.

- There was no outside emergency lighting.

- The first-aid supplies were inadequate.

- The fuel tank on locomotives should be better protected.

1.14.2 VIA OBS personnel

VIA OBS employees expressed the following concerns:

- The hammers were inadequate to break emergency exit windows.

- Intermixing of manual and power-operated doors was confusing.

- Employees should be provided with arm bands to be worn in the event of an emergency so that those in charge are easily identifiable.

- VIA equipment should be provided with portable lighting (flashlights).

- Outside emergency lighting should be provided on VIA equipment to assist in evacuation procedures.

- The intercom system should be designed so that it can be used on emergency power.

- The location where first-aid or emergency equipment is stored should be equipped with emergency lighting.

- Batteries capable of providing emergency lighting for a longer period of time should be provided.

- OBS employees should be provided with more enhanced emergency training procedures.

1.14.3 Passengers

Approximately 160 questionnaires were sent to passengers by the TSB, requesting their comments concerning the occurrence. More than 100 passengers responded. The most common concerns were as follows:

- Although many passengers in the club car credited OBS employees with saving their lives, they indicated that, in the extreme condition in the first two cars, the OBS employees were confused and unable to give basic instructions.

- Emergency exit windows could not be broken.

- VIA employees did not wear any type of clothing that made them easily identifiable in the darkness.

- There was no emergency portable lighting.

- There was no outside lighting to assist passengers detraining into the darkness during the emergency.

- Passengers were not provided with adequate information during the emergency nor was there any means, such as a PA system, to broadcast information.

- Emergency first-aid equipment was inadequate.

- There was no emergency information available at each seat.

VIA employees situated in the cars away from the extreme conditions were perceived, by passengers, as calm and reassuring.

1.15 Training and education

1.15.1 VIA employees

VIA's Train Emergency Procedures, which became effective in October 1989, provide for three days of training for OBS personnel and VIA operating crew members every three years in the following:

- evacuation procedures;

- procedures for on-board fires;

- emergency first aid;

- bomb threat procedures; and

- emergency response equipment.

Rules, information and instructions are intended to safeguard passengers from hazards, to enable them to avoid behaviour liable to jeopardize safety and to make full use of the hardware devices provided for their protection, and to facilitate their swift and safe evacuation.Footnote 2

Research has shown that the style of instructions given by passenger service personnel in an emergency can be very important. Instructions should be given in the form of short, simple commands to achieve maximum comprehension. Negative commands, such as "Don't do this" are easily misinterpreted as the leading negative qualifier may not be heard. This results in the opposite of the desired effect.

At the time of the occurrence, the VIA training program in evacuation procedures and fire-fighting consisted of lectures and demonstrations. There was no simulation or opportunity for trainees to practice the component tasks. The training material provided by VIA described procedures and included guidelines for evacuation.

The VIA General Instructions to Train Conductors and Manual of Service Instructions include information on preferred methods of evacuation. However, conductors or OBS personnel did not actually practice the task during their training. They were not instructed in the best way to communicate directions to passengers or speech mannerisms to avoid in an emergency, and were not required to practice these skills.

Fire-fighting training for conductors and OBS personnel included watching a 20-minute video on fire-fighting with portable fire extinguishers. Conductors and OBS personnel did not operate a fire extinguisher or put out any kind of fire during the training sessions. At the time of the occurrence, the training did not include practice or demonstrations in the use of emergency exit windows.

The purpose for training in procedures, such as emergency evacuation, is to ensure that skills are learned and will be transferred from the training situation to the job when the need arises. Several factors affect the degree to which transfer will be accomplished:

- Transfer of training is greatest when the training conditions are highly similar to those of the ultimate testing conditions.

- The greater the amount of practice on the original task, the greater the likelihood of positive transfer; negative transfer is likely to occur following only limited practice on the original task.Footnote 3

Different types of skills which, once learned and not practiced for periods of time, are subject to degradation at different rates. Continuous movement skills, such as controlling a vehicle, are relatively impervious to decay. Tasks requiring decision making and recall of facts from memory, e.g. Canadian Rail Operating Rules (CROR), decay more quickly. Skill at tasks which require verbal communication between personnel, however, are subject to fairly rapid decay if not practiced.Footnote 4

Controlling an emergency evacuation from a burning train would obviously require rapid assessment of a situation, quick and accurate decision making in a stressful circumstance, and effective communication with passengers.

1.15.2 Passenger safety education

Studies show that passengers who are instructed in the use of emergency equipment perform better than those who are not. The relevance of this to real-life events was demonstrated by an aviation investigation which showed that 56 per cent of passengers who had not read passenger safety information cards were injured during the evacuation. Of those who had read the card, only 17 per cent were injured.Footnote 5

1.16 Other information

The piece of rail which had been placed on the track, resulting in this occurrence, had originally been removed from the north main track, approximately 400 feet east of the Ontario Street public crossing, during routine railway maintenance, about three months before the occurrence. It had been left, with other scrap material, beside the north main track, near the Ontario Street crossing.

As a general practice, CN maintenance supervisors determine when the time is appropriate for the pick-up of scrap material that has accumulated along railway rights-of-way. There is no set time table in place that dictates when this should be done.

2.0 Analysis

2.1 Introduction

VIA 66 was being operated in accordance with government safety standards and railway operating instructions. The locomotive engineers had observed the piece of rail just before impact but, travelling at 96 mph, stopping would have required approximately 6/10 of a mile, thus avoidance by braking was impossible.

When the fire was observed, the operating crew applied a full service brake application and quickly executed the required emergency procedures to protect their still moving but disabled train. The fire, however, created an immediate and extreme risk to the well-being of passengers and VIA employees. Train speed did not diminish as quickly as expected, prolonging the effects of the wind-driven fire. During this occurrence, it has been confirmed that emergency exit procedures and equipment were deficient.

The analysis will address the cause of the fire, the train braking experience and all aspects of the emergency situation both in the cars and on the ground after the passengers exited the train.

2.2 Consideration of the facts

2.2.1 Damage caused by the piece of rail

The markings and damage under the lead locomotive and the gouging and marks on the track infrastructure were consistent with a situation where the piece of rail, after being struck by the locomotive pilot, wedged between the track structure and the underside of the locomotive, penetrating the left-side fuel tank and severing the electrical cables. The piece of rail was carried by the locomotive, likely with part of the piece of rail within the fuel tank, from the point where it entered the fuel tank until it reached the Prince Edward Street crossing where it fell down, tearing out the fuel crossover before bouncing away from the track.

Sparks from the arcing between severed electrical cables ignited the diesel fuel that was spraying out from the punctured left-side fuel tank and, in turn, ignited fuel leaking from the fuel crossover from the right-side tank. The speed of the train gave rise to a situation where the fuel was mixed rapidly with air, thereby facilitating rapid combustion and resulting in a very hot fire plume which engulfed the rear of the lead locomotive and the first two cars.

The electrical cables were not protected from the impacts of foreign objects and were situated in a vulnerable location. The fuel tanks were similarly exposed along the exterior of the locomotive. They were riding only 6 1/2 inches (16.3 cm) above the rail head and both the tanks and cross-feeds were not protected against impact. The placement and exposure of both systems increased the possibility of fire with resultant risk to the safety of passengers and crew members.

It is also noted that such damage can drain the entire contents of both fuel tanks. In this case, the continuous volume of fuel released prolonged the time required to stop the train and the time that the fire was fuelled. Baffled or compartmentalized tanks, puncture-resistant and self-sealing bladders or foam inserts could have been installed. These would have restricted the quantity of fuel released and reduced the severity of the fire, the stopping distance of the train and the length of time the fire acted on the club car and coaches. Such provisions, in other words, could have reduced the hazards to the passengers and crew members on board.

The hazards posed by the fire were considerable. Nonetheless, given the size and weight of the piece of rail, VIA 66 could also have derailed. A derailment at a speed of 96 mph could have caused the club car or coaches to fall on their sides, undoubtedly putting the passengers and crew members even more at risk. The locomotive pilot does not have a slope or angled surface so that all objects on the track are deflected from the path of the train.

2.2.2 Post-collision train handling

The event recorder data confirmed the sequence of events, before and after impact with the piece of rail, as outlined by the locomotive engineers. As the train approached the crossing, at a recorded speed of 96 mph, whistling for the crossing was interrupted, followed by a power reduction to idle and a full service brake application. A full service brake application, in consideration for the comfort and safety of the passengers, was appropriate as the severity and consequences of the impact were unknown. The complete brake pipe pressure loss, 14 seconds later, which would have activated the emergency brake system and triggered the automatic sanding indication (it should be noted that LRC locomotives are no longer equipped with operational sanders), was likely the result of the fire burning through the brake pipe. The momentary locomotive brake bail-off, after the emergency brake application, was likely a conditioned response to training by the locomotive engineer as VIA advocates locomotive brake bail-off in most circumstances to lessen the possibility of damage to locomotive wheels.

It took approximately 10,600 feet (measured in the field) and an estimated 144 seconds (see Figure 2) for VIA 66 to stop, more than three times the normal stopping distance and nearly four times the stopping time of a similar train, according to computer simulation. The abnormally long time to stop the train increased the risk to the passengers and employees and contributed to the extent and intensity of the fire.

The reasons for the longer-than-normal stopping distance and stopping time are not clear. In theory, the fact that initially only a full service brake was applied and retained for 14 seconds before the emergency braking applied could be argued to be a factor. However, the event recorder data clearly show a relatively uniform rate of deceleration for the service brake application and the emergency brake application (see Figure 2).

The fuel that was released from the fuel tank and subsequently sprayed back lubricated the rail/wheel interface and the braking mechanisms, thereby reducing the braking efficiency. The first locomotive engineer felt that the wheels were sliding as the train braked. A brake mechanism failure as a result of the fire or the electrical failure is possible but the nature of the deceleration of the train does not support this possibility. The lubrication of the rail heads, wheels and the brake mechanisms with diesel fuel is consistent with the relatively slow deceleration of the train.

Both the lead and trailing locomotive event recorder data indicated an anomalously fast deceleration beyond the point where the recorded speed had reached 39 mph and 32 mph respectively. While it is normal for the speed of a train under emergency braking conditions to decelerate at a faster rate as the train speed gets closer to 0 mph, the recorded deceleration rates do not appear to be reasonable. For instance, the trailing locomotive appeared to decelerate linearly to 32 mph while the lead locomotive decelerated to 39 mph before the speed rapidly declined to 0 mph. Such a deceleration probably would have resulted in the passengers and crew members being thrown forward -- something no one on board recalled. This therefore suggests that the recorded rapid deceleration likely did not occur. There are several explanations in support of this contention: the wheels were skidding on the lubricated rails; therefore, the recorder would have registered 0 mph velocity even though the train was moving; the fire caused electrical problems which were manifested in incorrect transmissions or disruption of the event recorder; or a combination of both.

The nature of the recorded data on the event recorders does not, however, support the view that there was a massive electrical failure affecting the recorders. Furthermore, if the linear deceleration rate below 40 mph was similar to that above 40 mph, the calculated stopping distance would have been close to that measured at the occurrence site. It is therefore concluded that the recorded speed of the train, below 40 mph, was not correct and that the wheels skidded on the diesel fuel-covered rails below 40 mph.

2.2.3 Safety of LRC passenger cars

In an emergency situation on a train, a safe environment for passengers is one where:

- the risk of striking or being struck by objects during deceleration is minimal;

- passengers are provided with a quick and safe means of exit, no matter what the orientation of the equipment;

- emergency lighting illuminates exits, emergency equipment and instructions, and the interior and exterior of the passenger cars;

- there are clear, posted instructions giving guidance for emergency procedures; and

- first-aid supplies are of appropriate quantity and quality for most emergency situations.

There was no indication that injuries were incurred as a result of striking or being struck by sharp objects during the train deceleration. The fully secured overhead bins and coach design minimized such risks. Passengers encountered difficulties and injuries in exiting the equipment, by conventional or emergency exits, which was complicated by their inability to see in the dark and smoky conditions with no pre-knowledge or instructions of what to do in such an emergency. As well, first-aid supplies were of inadequate quantity and quality for the nature and extent of injuries.

2.2.3.1 Ease of conventional exit

In an emergency, one of the first reactions of a passenger is to try to exit the equipment. In an LRC coach, as many as 72 passengers (52 in an LRC club car) are faced with up to two corridor doors, the vestibule door and the vestibule stairs to exit. Each presents a potential barrier and, if one does not function easily or quickly, panic can set in, leading to such things as breaking and jumping from windows even while the train is moving.

In this respect, there were difficulties in opening the corridor door in the club car. This was because of a number of factors including:

- the lateral pressure of passengers leaning against the door;

- the force (37 pounds) required to move the door when power was lost;

- the lack of knowledge of how to open the door (perhaps complicated by the power- or manual- opening options);

- the fact that there were no written instructions on how to open the door; and

- the complications arising from panic and vision impairment from smoke and inadequate emergency lighting.

Although there was no evidence that the corridor doors were not operating as designed, the examination of corridor doors after the occurrence at the VIA TMC revealed two defective doors on three cars that had been released for service. This may be indicative of inadequate pre-departure inspections and door maintenance.

Although the vestibule doors were eventually deployed, it is considered that the force required to activate the "T" handle (98 pounds), the handle positioning in the ceiling, and the lack of instruction on its operation rendered manual deployment by other than a VIA employee extremely difficult and impossible for some passengers. The pictograms, half of which indicated the vestibule door sliding in the wrong direction, could also have impaired or even precluded successful manual operation of the door. Once the vestibule doors were deployed, there were difficulties and resultant injuries to passengers exiting by the vestibule stairs because of their height above the roadbed and the lack of lighting to illuminate the ground below the steps.

The exterior operating controls for vestibule doors were not identified as to their use and function, and in all likelihood, could not be found or activated by a passenger or first responder.

2.2.3.2 Emergency exits

By the very nature of passenger car design, windows provide the most ready means of escape in emergency situations if a car remains upright. Passengers, however, when exiting from a window, find themselves having to jump from a sill which is nearly 7 feet (2.1 metres) above the top of the rails and probably 8 feet (2.4 metres) above ground level. Passengers on VIA 66 were injured from jumping (broken bones and sprains). Windows equipped with standard safety glass, when broken by impact, leave shards of glass, which can inflict serious injury (cuts) as passengers make their exit. It is apparent that, although windows can and will be used as a means to escape life-threatening circumstances, it is important to limit the need to use this exit method to the extent possible.

In this occurrence, the emergency exit windows equipped with tempered glass proved to be a barrier. The hammers provided to initiate the cracking process were not made with material of sufficient hardness to penetrate the surface of the glass and propagate window failure. It was also noted that few passengers were aware of the emergency hammer concept and, in the darkness, those who were, could not, in most cases, locate the hammers or those windows identified as emergency exit windows. The tempered glass, which is extremely resistant to impact damage, could not be easily broken, thereby rendering most emergency window exits unusable.

It cannot help but be observed that, if a passenger car was in other than an upright position, i.e., on its side, emergency escape would be even more difficult. The feasibility of opening the vestibule doors, the corridor doors or breaking the glass in either the emergency or standard windows overhead would be extremely difficult. Immersion in water, usually resulting in the car resting at an angle, would present a similar situation with further complications.

Given the number of passengers that could be within an LRC coach (72) or club car (54) and the possibility of a car ending up on its side or in water after a collision or derailment and the possibility of fire, the present emergency exits are inadequate.

2.2.3.3 Necessary emergency exit improvements

From the facts of this occurrence and the known possibilities posed by a derailment or collision, it is apparent that LRC passenger cars do not provide adequate means of escape for all passengers and crew members in life-threatening situations. Possible means of improving the emergency exit provisions of passenger equipment include:

- the installation of strategically positioned and mechanically operated emergency doors or panels extending to floor level similar to exit doors on large passenger aircraft;

- the installation of strategically positioned and mechanically operated emergency exit hatches in car ceilings;

- the modification of corridor doors so that they open with minimal force when power is lost or open automatically on demand (button, lever, or pad) in an emergency situation such that the doors remain open upon activation;

- the assurance that, when as a last resort passengers and crew members must exit through any of the windows, all windows would break under the force of fists or feet without shards of glass being held in place by gasket materials; and

- the posting and communication of instructions to passengers as to all emergency exit features and their operation.

2.2.3.4 Emergency lighting and power

Emergency power activated as designed. Emergency lighting and emergency power door operation initially functioned throughout the train.

The emergency power to the first two cars (the club car and coach 3349) quickly failed, likely due to fire damage, and emergency power to the third car was of short duration. Loss of emergency power which, in night-time conditions, leaves the cars in darkness also rendered corridor doors very difficult to open, as a 37-pound lateral force applied to small finger hold slots was required to move the door open. Such a requirement is impossible for many people and, when coupled with darkness, smoke, fire and panicking passengers attempting to exit the car, could make the corridor doors impassable.

Emergency lighting provides sufficient luminescence within the seating area, washrooms, the corridor and vestibule areas to allow passengers to see as they vacate the cars. Emergency equipment (i.e. break-out hammers, fire extinguishers, first-aid supplies, etc.) and emergency instructions or pictograms were not illuminated. Lighting of these features would have improved passenger knowledge and, hence, safety in emergency night-time situations. Similarly, there was no provision for exterior emergency lighting and passengers were injured as they stepped off the vestibule stairs onto uncertain terrain in the darkness. Some were also hurt while moving about outside the train. Exterior emergency lighting would also have assisted in the administering of first aid and increased the ability of passengers to identify and respond to the instructions of VIA employees.

The quick loss of emergency power to the third car, coupled with the information respecting the length of emergency power supply on two cars at the Ottawa Station on 10 December 1994 (one car, 10 minutes and the other, one hour), indicates a safety deficiency in the design and/or maintenance of the emergency power system.

The 55-volt cut-out, coupled with the distinct possibility that the system could contain weak batteries, jeopardizes the emergency power supply. The system is designed to provide two hours of power under optimum weather conditions (20 degrees Celsius). At a temperature of minus 20 degrees Celsius, a usual winter-time temperature, the design time is cut roughly in half. Since battery maintenance procedures are such that batteries are only changed once they are inoperative, and malfunctioning batteries or old inefficient batteries are not routinely checked and removed, the possibility exists for weak batteries to be present in the battery banks. The 55-volt cut-out threshold could be quickly reached and emergency power cut out. The emergency power supply system as designed and maintained is therefore inadequate for emergency situations.

The portable lights (flashlights) supplied by VIA were of insufficient quantity, size, and strength (luminescence) to be of much help. Lighting was needed to assist in the rendering of first aid, walking around and away from the train and moving through the rough terrain away from the area.

2.2.3.5 Emergency instructions

A variety of emergency information and instructions were posted at various locations throughout the cars. Instructions for the emergency operation of the doors or use of emergency break-out hammers were provided by pictograms. Emergency information was conveyed on a grey placard located in only two locations -- one at each end of each car. In night-time conditions, even with the emergency lighting activated, this posted emergency information would be difficult to see. Smoke would further diminish visibility.

In some forms of public transportation, written emergency information is available at each seat where passengers can familiarize themselves with procedures. Given the general lack of knowledge of the emergency features, it is believed that, if each seat were supplied with written emergency information, safety would be enhanced -- something that VIA introduced shortly after this occurrence.

The PA system was not designed to function on emergency power. It was therefore difficult for VIA employees to instruct and direct passengers. Both passengers and VIA employees identified this as a significant deficiency. Indications are that it would be beneficial if such a system not only functioned on emergency power, but also was audible outside the train.

2.2.3.6 Emergency supplies

The fact that a multi-trauma first-aid kit was supplied in club cars only, which in this instance was destroyed by fire, left only basic first-aid supplies (adequate for minor injuries to two or three passengers per car). The lack of other-than-basic first-aid supplies could result in injured passengers not obtaining proper and timely care and, in this instance, was described by first-aid givers as hampering their efforts. The basic first-aid supplies are not adequate for the number of injured that would be expected from almost any serious VIA occurrence affecting passengers. It is also noted that not all VIA trains include a club car and, thus, all trains would not have a multi-trauma kit.

Although the available first-aid kits were complete, there was no procedure in place to ensure that this was always the case. The possibility exists for supplies to be removed and not be replaced which could affect first-aid procedures in the event of an emergency.

Oxygen equipment was found to be considerably out of date for testing and refill. Improperly identified black and white oxygen cylinders and some with no markings to identify the contents could impair first-aid procedures in the event of an emergency requiring their use.

In general, the emergency supplies on VIA 66 were not consistent in type, quantity or quality with that which would adequately minimize risk in the event of most emergencies.

2.2.4 Emergency procedures

The nature of the occurrence, with fire and smoke, was a rare event for all VIA employees. Given the on- board panic and the evacuation problems, it appears that a comprehensive training program, including simulated evacuation procedures, the use of emergency equipment, first aid, and effective communication as well as required periodic practice, would have reduced risks.

If not adequately prepared for such events, it is unlikely that VIA employees can take the immediate action required, much less control and motivate a large number of people to act appropriately in an emergency. The ability to handle emergencies was illustrated in the different passenger perceptions between the front and rear cars. Passengers in the cars where there was fire and smoke were critical of the emergency response of the VIA employees in the areas of communication and direction. In the cars where there was no fire, VIA employees were perceived as calm, competent, and reassuring.

It is known that skills, especially decision making and tasks requiring communication, will decay unless practiced. Therefore, recurrent training should include evacuation and emergency crowd control communication techniques. The hierarchical structure of train crews, with the conductor exercising overall authority and the OBS personnel assuming responsibility for specific passenger safety tasks, indicates that operating employees and OBS personnel should undergo some form of joint training in passenger safety and emergency procedures.

2.2.5 Other considerations

2.2.5.1 Combustion products

VIA had upgraded the specifications for interior materials used for refurbishing the LRC cars in 1993. Although there is no related government specification in effect, the upgraded material was apparently satisfactory. There was no evidence of toxic gas emissions as a result of the combustion of the interior components of the club car or coach.

2.2.5.2 Right-of-way litter

Locomotive crew members have commented that they are continually subjected to scrap material such as pieces of rail and ties being placed on the track in the path of oncoming trains. The removal of scrap by track maintenance employees from areas readily accessible to the public -- particularly near public crossings and within residential areas -- is not sufficiently timely.

2.2.5.3 Safety Regulatory Vigilance

The large number of deficiencies uncovered in this one occurrence pertaining to the design, operation and maintenance of LRC passenger equipment, from a safety point of view, leads to the conclusion that there is a need for more safety standards and regulatory overview of emergency facilities, training, maintenance and operations of the LRC rail passenger system in Canada.

3.0 Findings

3.1 Findings

- VIA 66 was being operated in accordance with government safety standards and railway operating instructions.

- A piece of rail left near a public crossing by CN track maintenance employees was found by police and the court to have been intentionally placed on the track by two local residents.

- The locomotive engineer at the controls reacted quickly by applying the brakes, but did not have sufficient distance to stop the train before striking the piece of rail.

- The piece of rail was positioned in such a way that it passed under the locomotive pilot.

- The design of the LRC locomotive pilot, without a sloping or angled surface, did not deflect the piece of rail from the path of the train.

- The piece of rail punctured one of the fuel tanks beneath the lead locomotive and severed electrical cables slung under the fuel tank.

- The leaking diesel fuel, highly dispersed in air because of the train speed, was ignited by sparks from electrical arcing between the ends of the severed electrical cables.

- The fuel tank and electrical cables under the locomotive were vulnerable to rupture and breakage from impacts with foreign objects which are not deflected by the locomotive pilot.

- Fuel tank and component design does not limit the quantity of fuel released when punctured.

- Difficulties in opening car doors caused panic among passengers in the club car and the first coach.

- VIA 66 took more than three times the distance and four times as long to stop than would be expected under usual conditions.

- The above-normal length of time that it took to stop increased the danger to the passengers and heightened their level of panic.

- The contamination of the rails and braking mechanism with diesel fuel significantly reduced braking efficiency, thereby increasing the stopping time and distance.

- A temporarily impassable corridor door in the club car forced passengers to jump from windows before and after the train had stopped.

- The difficulty in opening corridor doors was attributable to the 37-pound lateral force required to move them when power was lost and horizontal pressure being applied to the door from passengers attempting to exit.

- Corridor doors tested subsequent to the occurrence revealed that pre-departure VIA LRC door inspection and maintenance did not ensure that all doors operate as designed.

- The force of 98 pounds required on the overhead "T" handle to disengage power-operated vestibule doors to allow emergency manual operation is excessive.

- The overhead "T" handle is not positioned to provide easy access to all passengers.

- The flaps covering the exterior vestibule door features on both "normal" and "emergency" operation were not conspicuously marked or identified as to their use and operation.

- Pictograms displayed on the doors of LRC equipment were difficult to understand and, in some instances, displayed incorrect information.

- The posted information on emergency equipment and exits was of insufficient size, colour and content to meet the needs of passengers.

- Non-emergency windows both melted, cracked, and exploded in the heat and were broken out by passengers using their feet and fists.

- The break-out hammers provided for breaking emergency tempered glass windows were of inadequate hardness to break the windows.

- The tempered glass emergency windows proved to be barriers for passengers attempting to exit when the break-out hammers did not break the glass as intended.

- Passengers were cut and injured as a result of exiting the train from the window openings.

- The use of windows as a designed means of emergency escape placed passengers and crew members at unnecessary risk.

- The public address system did not function on emergency power, denying VIA employees the means to effectively direct and manage both the evacuation of the train and passengers congregated on the right-of-way.

- The lack of outside emergency lighting, the unavailability of portable lighting (e.g. flashlights) and the fact that VIA employees did not wear any type of clothing that made them easily identifiable in the darkness made evacuation from the train and the occurrence site inefficient and hazardous.

- The emergency power system on LRC equipment cannot be relied upon to function a reasonable length of time, has no performance standard for low temperatures, and is not likely properly monitored to ensure maximum performance.