Air transportation safety investigation report A23O0008

Loss of control in flight

Chartright Air Inc. (dba Chartright Air Group)

Cessna 560 Encore, C-FYMM

Vicinity of Cayuga, Ontario

The Transportation Safety Board of Canada (TSB) investigated this occurrence for the purpose of advancing transportation safety. It is not the function of the Board to assign fault or determine civil or criminal liability. This report is not created for use in the context of legal, disciplinary or other proceedings. See Ownership and use of content.

-

Table of contents

Summary

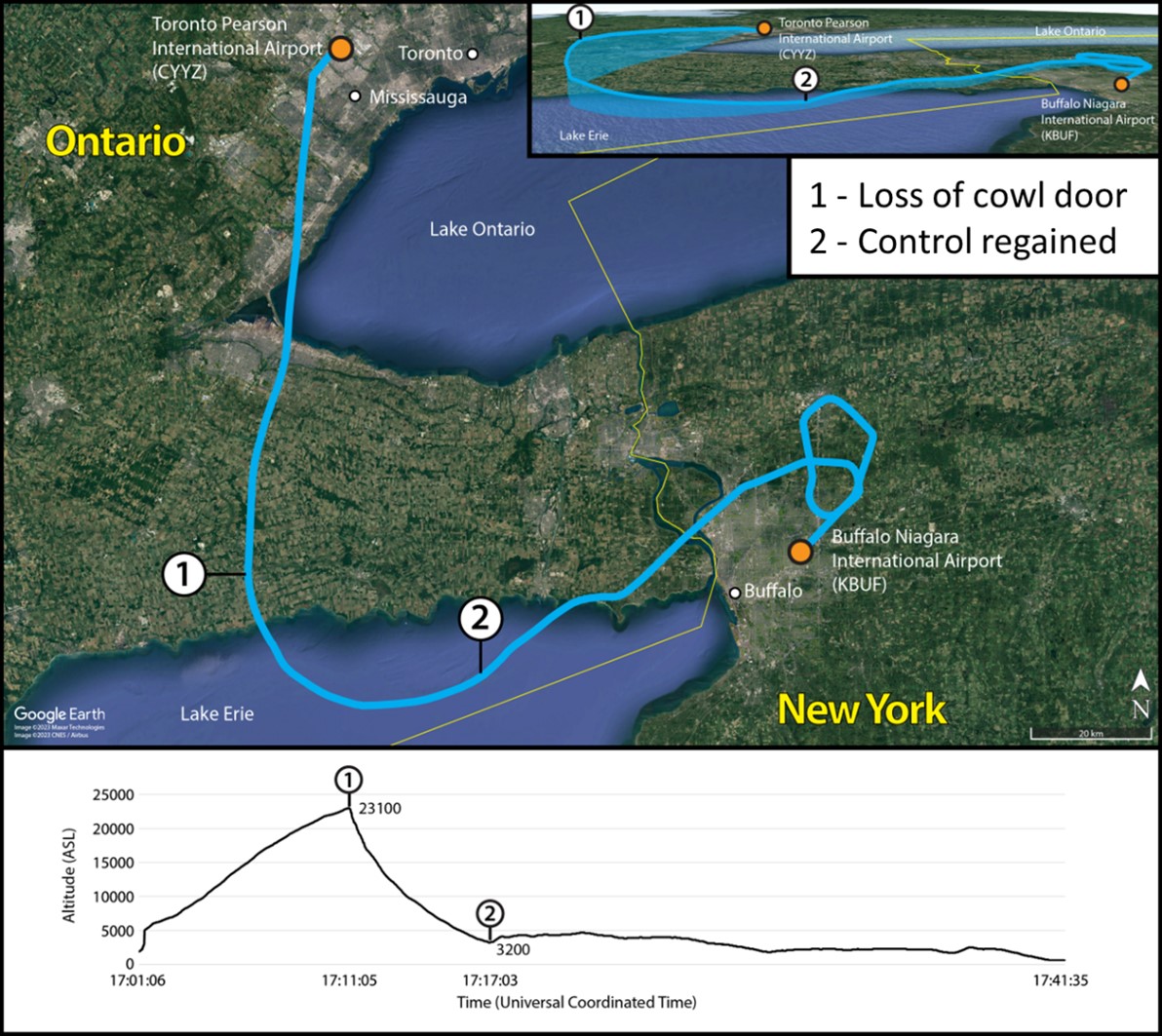

On 27 January 2023, a Chartright Air Inc. (doing business as Chartright Air Group) Cessna 560 Encore (registration C-FYMM, serial number 560-0705) was conducting an instrument flight rules flight from Toronto/Lester B. Pearson International Airport (CYYZ), Ontario, to Fort Lauderdale Executive Airport (KFXE), Florida, United States, with 2 flight crew and 3 passengers on board. Shortly after takeoff, while the aircraft was climbing to cruise altitude, the engine cowl doors detached from the left-engine nacelle, resulting in a loss of control of the aircraft. After a significant loss of altitude, the flight crew regained control of the aircraft, declared an emergency, and diverted to Buffalo Niagara International Airport (KBUF), New York, United States, where it landed without further incident. While the aircraft was taxiing, a remaining piece of the lower cowl door fell from the aircraft. No other pieces of the cowl doors were located. The aircraft’s aft fuselage and horizontal stabilizer were damaged. The flight crew and 2 passengers received minor injuries, and 1 passenger received serious injuries.

1.0 Factual information

1.1 History of the flight

At approximately 1325Footnote 1 on 23 January 2023, the Chartright Air Inc. (doing business as Chartright Air Group) Cessna 560 Encore aircraft flew to Toronto/Lester B. Pearson International Airport (CYYZ), Ontario, for maintenance work at the company’s maintenance hangar. The work to be performed, which would address 2 reported defects, required the removal and reinstallation of the lower cowl doorsFootnote 2 on both the left and right engines. In addition, a daily inspection (DI) of the aircraft was to be conducted. A team of 3 aircraft maintenance engineers (AMEs) began with the troubleshooting of the reported defects, followed by the DI, the final engine cowl door installation, and the completion of the applicable maintenance documents. By the end of the day, all of the maintenance work, along with the DI, was completed, and 1 of the 3 AMEs involved signed the maintenance release for both tasks. The aircraft was kept inside the hangar until the day of the occurrence flight.

On 27 January 2023, the aircraft was scheduled to conduct an instrument flight rules flight from CYYZ to Fort Lauderdale Executive Airport (KFXE), Florida, United States (U.S.). Starting at approximately 1100, the captain and first officer each performed a pre-flight walkaround inspection in preparation for the flight. After the passengers had boarded the aircraft and the baggage had been loaded, the captain conducted another walkaround. Approximately 1 hour later, at about 1200, the aircraft took off from CYYZ on Runway 23, with 2 flight crew and 3 passengers on board.

At approximately 1211, while the aircraft was in climb over Cayuga, Ontario (approximate location), at an altitude of approximately 23 000 feet above sea level (ASL), the whole upper cowl door and most of the lower cowl door on the left engine partially detached from the nacelle, before becoming completely detached, resulting in a sudden increase in parasite drag on the left side of the aircraft. The aircraft suddenly yawed and rolled to the left, and the flight crew then lost control of the aircraft as it rapidly lost altitude. The flight crew subsequently declared an emergency by transmitting a Mayday call, and at approximately 3200 feet ASL, they regained control of the aircraft and stopped the descent (Figure 1).

The flight crew requested a diversion to Buffalo Niagara International Airport (KBUF), New York, U.S. They subsequently burned off some of the aircraft’s fuel and followed air traffic control (ATC) guidance. Although the aircraft remained difficult to control, the crew landed on Runway 23 at KBUF at approximately 1241, with aircraft rescue and firefighting (ARFF) emergency vehicles standing by. While the aircraft was taxiing to the ramp, a remaining portion of the lower cowl door fell off the horizontal stabilizer onto the taxiway. After the aircraft came to a stop on the apron, ARFF informed the flight crew that the remaining portion of the cowl had detached from the aircraft.

All of the occupants were able to exit the aircraft on their own. Those with injuries were transported to hospital.

1.2 Injuries to persons

There were 2 flight crew members and 3 passengers on board. Table 1 outlines the degree of injuries received. There were no reports of injuries to persons on the ground caused by the falling aircraft parts.

| Degree of injury | Crew | Passengers | Persons not on board the aircraft | Total by injury |

|---|---|---|---|---|

| Fatal | 0 | 0 | 0 | 0 |

| Serious | 0 | 1 | 0 | 1 |

| Minor | 2 | 2 | 0 | 4 |

| Total injured | 2 | 3 | 0 | 5 |

1.3 Damage to aircraft

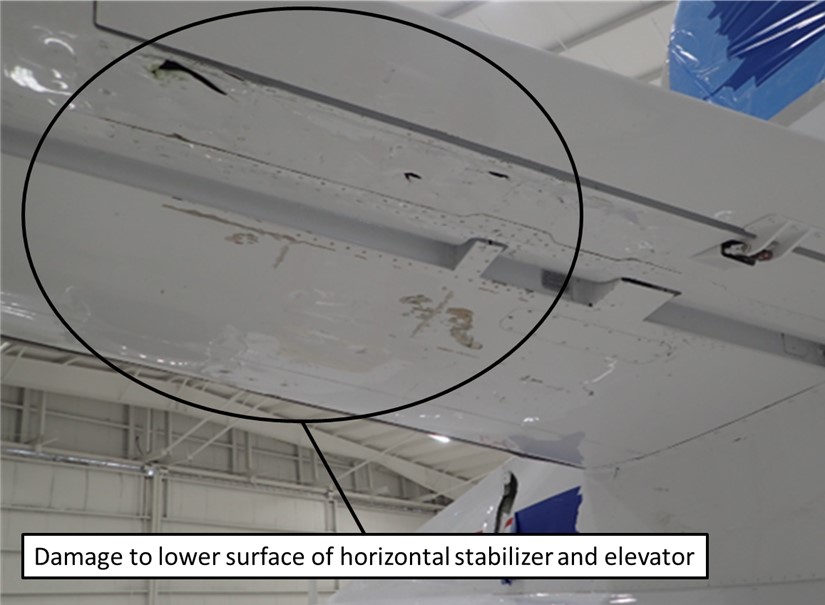

The aircraft sustained substantial damage caused by the detachment of the upper and lower left-engine cowl doors while the aircraft was in flight (Figure 2).

The left side of the fuselage, near the engine, and the left side of the vertical stabilizer were dented in several locations (Figure 3). A section of aluminum skin on the vertical stabilizer, covering approximately 150 square inches near the base, was punctured and torn.

On the left horizontal stabilizer, the leading edge was dented, and the de-icing boot had been cut in multiple locations. Its upper and lower surfaces, as well as those of the elevator, were also dented and punctured in different locations (Figure 4).

The aircraft’s interior also had minor damage due to moving objects and occupants during the loss of control.

1.4 Other damage

There were no reports of damage on the ground caused by the falling cowl doors, which were not recovered.

1.5 Personnel information

1.5.1 Flight crew

| Captain | First officer | |

|---|---|---|

| Pilot licence | Airline transport pilot licence | Commercial pilot licence |

| Medical expiry date | 01 June 2023 | 01 September 2023 |

| Total flying hours | 2803.1 | 2174 |

| Flight hours on type | 440 | 61.2 |

| Flight hours in the 7 days before the occurrence | 7.4 | 2.2 |

| Flight hours in the 30 days before the occurrence | 44.1 | 21.4 |

| Flight hours in the 90 days before the occurrence | 130.1 | 61.2 |

| Flight hours on type in the 90 days before the occurrence | 130.1 | 61.2 |

| Hours on duty before the occurrence | 1.5 | 1.5 |

| Hours off duty before the work period | 14 | 14 |

Both pilots held the appropriate licences for the flight in accordance with existing regulations.

1.5.2 Aircraft maintenance personnel

Two of the 3 AMEs who were involved in the maintenance work before the occurrence performed the reinstallation of the engine cowl doors on the occurrence aircraft. Both held a valid AME licence issued by Transport Canada (TC), with the applicable rating for the aircraft category. They had also completed the applicable aircraft type training for the Cessna 560 Encore. In September 2022, Chartright Air Inc.’s approved maintenance organization (AMO) issued an aircraft certification authorityFootnote 3 to both AMEs for the Cessna 560.

Training records indicate that both AMEs received the mandatory technical, regulatory, and human factors training required by Canadian Aviation Regulations (CARs) Subpart 573.Footnote 4

On 23 January 2023, 3 AMEs (designated AME 1, 2 and 3 in the report) had been assigned to work on the aircraft. They started their workday between 0545 and 0600. AME 3 finished his workday at 1800; AMEs 1 and 2 had to stay after their normal working hours to complete their tasks and they finished at approximately 1845.Footnote 5 AME 1, who signed the maintenance release for the work on the left engine, was on his 4th consecutive day of working this schedule after 2 consecutive days off.

1.6 Aircraft information

1.6.1 General

| Manufacturer | Cessna Aircraft Company* |

|---|---|

| Type, model and registration | 560 Encore, C-FYMM |

| Year of manufacture | 2006 |

| Serial number | 560-0705 |

| Certificate of airworthiness date | 27 October 2006 |

| Total airframe time | 13 500.4 hours |

| Engine type (number of engines) | Pratt & Whitney Canada PW535A (2) |

| Maximum allowable takeoff weight | 16 830 lb (7634.1 kg) |

| Recommended fuel type | Jet A, Jet A-1, Jet B, JP-4, JP-5 and JP-8 |

| Fuel type used | Jet A-1 |

* Textron Aviation Inc. (Textron) currently holds the type certificate for the aircraft type.

The Cessna 560 Encore is a pressurized, turbofan-powered business aircraft. The maintenance program for the aircraft is based on a maintenance schedule approved by TC in accordance with Appendix D of CARs Standard 625.Footnote 6

There were no deferred defects at the time of the occurrence.

1.6.2 Aircraft maintenance

1.6.2.1 Maintenance work

The most recent maintenance work performed on the occurrence aircraft was completed at CYYZ on 23 January 2023, 4 days before the occurrence flight. Maintenance personnel troubleshooted 2 defects reported by the flight crew who had flown the aircraft back to CYYZ from Palm Beach International Airport (KPBI), Florida, U.S., and then conducted a DIFootnote 7 on the same day.

The work package for the maintenance performed on the occurrence aircraft on 23 January 2023 included the DI task card and the inspection sheet, which included specific items to check the condition and security of the engine cowls and doors on both the left and right engines. The work package also included task cards for the scheduled monthly items and the rectification of the 2 reported defects. The first defect was related to a fuel flow indication for the left engine at start up, and the second defect related to an intermittent low hydraulic flow indication when using the hydraulic system after landing.

The first defect required the AMEs to remove the left- and right-engine lower cowl doors so that they could have access to the fuel flow transmitter. During the maintenance operation, the left-engine lower cowl door had to be removed a second time after an engine test run so that safety wires could be installed on the fuel flow transmitter electrical connection. AMEs 1 and 2 reinstalled the cowl door while the 3rd was completing service on the oxygen system, which was part of the DI. The DI items and the maintenance entries in the applicable technical documents were subsequently completed. There was no further maintenance activity conducted on the aircraft before the occurrence.

1.6.2.2 Steps followed during the left-engine lower cowl door reinstallation

Some company AMEs had adopted an informal routine for installing the cowl doors. To begin the reinstallation of the lower cowl door on the engine, one AME would normally pick up and hold the cowl door in place. The other AME would secure the middle fastener at the aft lower attachment point, then the middle-forward fastener to hold the panel in place.

The AMEs would then fasten a section of the cowl door, with one AME completing the entire forward row of fasteners and the other completing the entire aft row. The AMEs would normally work from the middle to the outboard and inboard sections of the cowl door. They would then work along the horizontal row of fasteners on the outboard portion of the nacelle, meeting in the middle.

On the day the fasteners were left unsecured on the left engine lower cowl door, the work progressed mostly as expected according to the normal routine. AME 2 held up the cowl door while AME 1 secured the middle lower aft fastener, then the middle-forward fastener, supporting the cowl door. Once the initial fasteners were secured, AME 1 then began securing more fasteners on the front section of the cowl door.

AME 2, who had been holding the panel in place, let go, picked up his screwdriver, and, instead of moving to the aft portion—which would have followed the normal routine—took over securing the vertical row of fasteners on the forward section, continuing from where AME 1 had been securing the outboard fasteners, partway through the section. The act of picking up partway through the task of securing the fasteners for a particular section was not part of the usual routine.

AME 1 then moved to the aft outboard section of the nacelle and started fastening the aft lower fasteners, working from the middle, upward to the outboard side. He then returned to the middle and worked upward toward the inboard side. At this time, AME 2 was fastening the horizontal line of fasteners from the front to the back.

When AME 1 was finished securing the aft fasteners, both AMEs finished securing the horizontal line of fasteners on the outboard portion of the nacelle, working toward each other. When the fasteners were secured, AME 1, who had been the first to secure the fasteners while the other was holding the panel in place, conducted a tap test,Footnote 8 but only at the aft outboard section of the nacelle.

Unbeknownst to both AMEs, the front inboard row of 6 consecutive fasteners remained unsecured. AME 1 then signed the DI item related to the condition and security of the engine cowls, including the cowl doors as well as the work on the left engine.

1.7 Meteorological information

The aerodrome routine meteorological report (METAR) issued for CYYZ at 1200, the approximate time of departure for the occurrence flight, indicated the following:

- Winds from 220° true (T) at 12 knots, gusting to 18 knots

- Visibility of 10 statute miles (SM)

- Broken ceiling at 1500 feet

- Temperature −1 °C, dew point −5 °C

- Altimeter setting 29.96 inches of mercury (inHg).

At 1224, while the occurrence aircraft was en route to KBUF after having declared an emergency, Buffalo ATC informed the flight crew that the winds were from 230°M at 16 knots, gusting to 22 knots.

The weather was suitable for the flight, and the loss of control and recovery of the aircraft occurred in visual meteorological conditions. Weather was not considered to be a factor in this occurrence.

1.8 Aids to navigation

Not applicable.

1.9 Communications

After the cowl doors had detached from the occurrence aircraft, the flight crew declared an emergency with ATC. The flight crew informed ATC that KBUF was their preferred diversion airport, and the crew was subsequently transferred to the KBUF approach frequency. ATC then vectored the aircraft for an instrument landing system approach on Runway 23 at KBUF and coordinated with the ARFF team so that it would be on standby for the aircraft’s landing.

1.10 Aerodrome information

KBUF is a 2-runway airport that is located in Cheektowaga, New York, U.S.

Runway 23, the airport’s main runway, is an asphalt runway that is 150 feet wide with an available landing distance of 7569 feet.

ARFF is among the emergency services available at KBUF.

1.11 Flight recorders

The aircraft was not equipped with a flight data recorder, nor was one required by regulation. However, it was equipped with a cockpit voice recorder, which contained recorded data for the duration of the occurrence flight. The data were successfully downloaded.

1.12 Wreckage and impact information

A post-occurrence inspection of the aircraft at KBUF confirmed that the whole upper cowl door on the left engine had detached from the engine nacelle during the flight and was missing. It was also observed that most of the lower cowl door had broken off from the aircraft in a similar fashion.

The portion of the lower cowl door that had fallen from the aircraft as it taxied off the landing runway was recovered. The marks found on this piece, as well as its shape, indicate that it had been stuck on the leading edge of the left horizontal stabilizer during the period of the flight between the detachment of the cowl doors and the taxi at KBUF. It also showed signs of elongation and torn material at the locations of the ¼-turn fasteners that had secured the cowl doors to the nacelles.

Following an inspection of the upper and lower cowl door attachment points on the left-engine nacelle, it was observed that several ¼-turn fasteners were still engaged in their receptacles. Marks and tiny remaining particles of the cowl doors surrounded the fastener grommets, likely a result of the cowl doors tearing around the fasteners before detaching from the engine nacelle.

At other attachment points, the ¼-turn fasteners were neither attached to the nacelle nor found on the recovered fragment of the lower cowl door. On the lower forward inboard section of the nacelle, there were 6 consecutive locations where the ¼-turn fasteners were missing.

A review of video footage from a camera located inside Chartright Air Group’s maintenance hangar, where the reinstallation of the left-engine lower cowl door had been performed, revealed that a series of consecutive fasteners had been left unsecured at the lower forward inboard edge of the lower cowl door. Such an opening would have allowed air to flow into the engine nacelle, causing increased vibration and tension at the attachment points that were secured.

1.13 Medical and pathological information

According to the information gathered during the investigation, there was no indication that the flight crew’s performance had been affected by medical or physiological factors.

1.14 Fire

There was no indication of fire either during or after the occurrence.

1.15 Survival aspects

At the time of the loss of control of the aircraft, both flight crew members were wearing their 4-point safety belts, and 1 passenger was wearing a lap belt. The 2 other passengers were not wearing safety belts because the seatbelt sign in the cabin was off at the time.

1.16 Tests and research

Not applicable.

1.17 Organizational and management information

1.17.1 General

Chartright Air Inc. is a TC–approved air operator authorized to operate aircraft under subparts 604 (Private Operators), 702 (Aerial Work), 703 (Air Taxi Operations), and 704 (Commuter Operations) of the CARs. The occurrence flight was conducted under CARs Subpart 704.

Chartright Air Inc. is also the holder of an AMO certificate issued by TC in the aircraft, avionics, component, and instrument categories. The aircraft category includes, but is not limited to, ratings for maintenance on Cessna 500, 525, 560 XL, 600, and 700 series aircraft.

The company has implemented a safety management system, even though it is not mandatory under the CARs for the type of operations that the company conducts.

1.17.2 Flight crew procedures

1.17.2.1 Flight crew walkaround standard operating procedures

The procedures for the pre-flight walkaround inspection conducted by the flight crew are outlined in the company’s standard operating procedures (SOPs).Footnote 9 Appendix L of the SOPs includes a detailed Exterior Inspection checklist for the Cessna 560 Encore.Footnote 10 However, at the time of the occurrence, this checklist did not specifically instruct flight crews to ensure, during the walkaround, that the engine cowl doors and ¼-turn fasteners were properly and securely installed.

Even though the flight crew conducted 3 walkarounds before the occurrence flight, they did not specifically look for unsecured fasteners on the cowl doors because the checklist did not have an item to specifically do so. In addition, the location of the inboard fasteners is not easily visible.

1.17.3 Aircraft maintenance personnel procedures

1.17.3.1 Training and authorization of aircraft maintenance personnel

The required training for the company’s aircraft maintenance personnel is described in its Maintenance Policy ManualFootnote 11 and Maintenance Control Manual (MCM),Footnote 12 both approved by TC, and includes the mandatory initial training required by CARs subparts 573 and 706.Footnote 13 Before they are granted an aircraft certification authority under the AMO, AMEs must meet the minimum training, qualification, and experience requirements.

1.17.3.2 Scheduled maintenance

Chartright Air Inc.’s Maintenance Policy Manual describes how the company conducts maintenance on aircraft and applicable components. Scheduled maintenance work is tracked through maintenance-tracking software (CAMP MTX). Before maintenance on an aircraft or component is initiated, a work package, consisting of the applicable documentsFootnote 14 informing the AMEs of the scope of the planned work, is prepared. The documentation also includes a provision to record information regarding the work performed and identify the authorized personnel who perform and certify the work.

1.18 Additional information

1.18.1 Manufacturer’s installation guidance

1.18.1.1 Installation instructions in maintenance manual

The Cessna 560 maintenance manual provides instruction for the installation and removal of the engine cowl doors. It specifies that the upper and lower cowl doors have quick-release fasteners (Figure 5) that can be unlocked when turned counterclockwise approximately ¼ of a turn.Footnote 15 The manual also explains that these fasteners have recessed heads to prevent tool slippage that could potentially lead to scratches and damage to the cowl door’s surface. A note at the beginning of the task warns technicians to “[u]se care when installing engine cowling. If the engine nacelle contacts an engine component other than at the attaching points, an audible rumble may be generated.”Footnote 16

![Left-engine nacelle (Source: Textron Aviation Inc., Maintenance Manual—Model 560-001 And On, Revision 36 [01 December 2019], Section 71-11-01, Figure 401, Sheet 1: Engine Cowling Installation, p. 3 of 5, with TSB annotations)](./images/a23o0008-figure-05.jpg)

The lower cowl door installation task is outlined in 2 steps:

- (a) Guide lower nacelle door over vent and drain tubes and starter-generator air cooling exhaust duct into position.

- (b) Align and secure quick-release fasteners along the nacelle inlet assembly, upper nacelle door and thrust reverser flange.Footnote 17

This installation procedure has been in effect since the last revision of the manual in December 2019. Since that date, concerns regarding the safety risks associated with the incorrect installation of cowl doors on other turbofan-powered Cessna aircraft have been identified both by the aircraft manufacturer, Textron Aviation Inc. (Textron), and by the Federal Aviation Administration of the United States (FAA). However, these details and concerns have not been included in the maintenance manual for the Cessna 560 Encore.

1.18.1.2 Cowl door installation training presentation

During the 2022 Textron Aviation Customer Conference, the aircraft manufacturer presented the issue of the engine cowl door becoming loose if not fastened properly. The presentation referred to previous incidents in which the engine cowl doors fully or partially detached from the engine nacelle in flight.

The presentation noted the following regarding the status of this issue:

- Maintenance error is primary cause

- If not properly secured, engine cowling can depart aircraft and cause damage

- FAA using Special Airworthiness Information Bulletin (SAIB) to alert operators of possible loose cowl fasteners

- Reminder to inspect properly before flightFootnote 18

The presentation concluded with a reminder that cowl doors should be inspected for correct installation before the maintenance release specifically to ensure that:

- ¼-turn fasteners are flush;

- cowl door contours match the remainder of the nacelle; and

- there are no cracks around the fasteners.Footnote 19

The presentation was made available through the approved Textron service network before the occurrence.

Chartright Air Inc. did not attend the 2022 Textron Aviation Customer Conference and was not aware of the presentation at the time of the occurrence.

1.18.2 Camloc ¼-turn fasteners

The ¼-turn fasteners on the occurrence aircraft were manufactured by Camloc Motion Control Ltd. and consist of a stud, a retaining ring, and a cam receptacle (also simply referred to as a cam). When a stud assembly on a cowl door panel is pushed into a cam on the nacelle and turned, the stud cross pin rides down the cam, pulling the 2 surfaces together and compressing the built-in spring. This action is accomplished by rotating the stud 90° (or a ¼ turn). Once the stud is turned, the cross pin falls into the locking detent, which holds the stud in place (Figure 6).Footnote 20 To release the fastener, the stud must be pushed further into the receptacle, so that it is released from the locking detent, and then turned a ¼ turn in the opposite direction.Footnote 21 When the stud cross pin is not engaged in the cam, the spring is extended and keeps the head of the stud above the surface of the aircraft panel, in the airflow.

![A ¼-turn fastener shown in the locked and unlocked positions (Source: Alcoa Fastening Systems, Camloc, Camloc Quick-Operating Fasteners [January 2009], p. A-4)](./images/a23o0008-figure-06.jpg)

1.18.3 Federal Aviation Administration Special Airworthiness Information Bulletin

On 29 April 2022, the FAA released SAIB AIR-22-10Footnote 22 on engine cowl system and ¼-turn fastener maintenance. Across Textron’s line of turbofan-powered aircraft, several incidents involving engine cowl damage and the resulting separation of engine cowl system components have occurred. As the bulletin explains, “[t]he separation incidents resulted in damage to the airplanes, and some incidents have marginally affected airplane handling capabilities.”Footnote 23

The bulletin aims to inform pilots, owners, operators, and maintenance personnel of turbofan-powered aircraft produced by Textron about the hazards associated with the engine cowl system, especially when ¼-turn fasteners are used to secure one component to another. The SAIB also aims to highlight the safety hazards and potential dangers of inadequate and infrequent pre-flight inspections of the ¼-turn fasteners, as well as the need for routine preventive maintenance.

To prevent occurrences involving engine cowl system damage and separation, the FAA issued the following recommendations:

The FAA recommends thorough pre-flight by all pilots, and repetitive inspections of the quarter-turn fasteners on engine cowl components. All airplane owners and operators should acquaint themselves with the configuration of the airplane, including the components that use quarter-turn fasteners. Knowledge of the location and correct installation configuration of quarter-turn fasteners will assist in any pre-flight or repetitive inspection to identify fasteners that are not normal or that may have changed since the last inspection.

In addition, engine maintenance activities require frequent cowl removals. Our investigation indicates that a single inspection may not always reveal an incorrect cowl re-installation. The FAA recommends a second visual inspection of the complete engine cowl installation immediately after a cowl has been removed and prior to returning the airplane to service to ensure that all quarter turn fasteners have been secured properly. Simple tools such as a ladder, flashlight, or mirror may assist in the inspection process. A complete inspection should consist of checking that all quarter-turn fasteners are correctly seated and latched.Footnote 24

The SAIB also lists common problems that technicians should look for:

- Improperly seated or improperly latched quarter-turn fasteners (most installations have some quarter-turn fasteners in which the installation cannot be viewed directly).

- Cowl doors with excessive forward edge gaps (distance to underlying surfaces that exceed aero-smoothness requirements. Excessive mismatch may result from quarter-turn fasteners with over- or undersized stud lengths or cowl door repairs that increase the door thickness).

- Cowl door cracks that weaken the area around quarter-turn fasteners.

- Cowl door contour anomalies.Footnote 25

The investigation found that 1 of the AMEs involved in the cowl door reinstallation had been aware of the content of the SAIB. Neither the operator, nor the flight crew, nor the AME who certified the work and the DI had been informed or were aware of the SAIB or its content before the occurrence.

1.18.4 Human factors issues

1.18.4.1 Skill-based performance in aircraft maintenance

There are 3 general ways to classify human performance from an information-processing perspective: skill-, rule-, and knowledge-based performance. Footnote 26 Skill-based performance is observed in familiar situations and tasks that require very little attention to perform. Typically, these tasks are relatively routine, predictable, and highly practised. Typing on a keyboard and transcribing information from a reference document to a written instruction could fall into such a level of performance. This level of performance is not chosen; rather, it becomes or is automatic.

The benefit of skill-based performance is that it is very fast and requires very little attention, freeing information-processing resources for other things. However, this benefit makes it susceptible to slips of attention and memory lapses, where the automatic routine is interrupted or disrupted during its execution and the interruption or disruption is not detected. Mitigations for skill-based performance slips of attention and memory lapses in maintenance activities include mental rehearsal for tasks, effective procedures, and the addition of good reminders in those task steps that have a high potential for slips of attention and memory lapses. Footnote 27,Footnote 28

1.18.4.2 Coordination of tasks

When operators, such as flight crews or AMEs, work together to achieve a task, communication, coordination, and task assignment are imperative for safe performance. One of the ways in which these aspects of team performance can break down relates to situations in which a member of a team develops unspoken expectations about a given task and then proceeds with the task without clarifying them or discussing them with any other members of the team.Footnote 29 This can generate inconsistent expectations between team members that can have a significant impact on team performance in a given situation.

In its training material, TC recognizes the risk posed by these hazards, exploring the lack of communication and the lack of teamwork as factors that can affect human performance.Footnote 30 Within the aviation industry, these hazards are typically mitigated by error-trapping strategies, such as SOPs or checklists designed to ensure clarity with respect to how a task is to be completed and which role each crew member plays in accomplishing that task.Footnote 31

An effective defence against these instances of unclear expectations or miscommunications involves pre-task briefings. In fact, in one U.S. study, inadequate briefings were identified as the second most common issue that led to the degradation of crew resource management.Footnote 32 Briefings do not necessarily have to be long or detailed, as long as the approach to completing the task and the team members’ roles in accomplishing it are clear. They can be especially valuable in the context of aircraft maintenance activities, where procedures often indicate what needs to be done (e.g., reinstall the lower engine cowl door) but not exactly how to complete the task.Footnote 33

AMEs often develop practices to accomplish a particular task in the safest, most effective manner possible based on their training and experience. However, because these are informal practices and not officially established procedures, it is possible that different expectations as to how the task will be completed can arise within a team of AMEs even if they are all generally aware of the same practice. Team members can benefit from a pre-task briefing for even the most routine, straightforward tasks because it is these types of tasks that have predetermined expectations, which tend to play a significant role in how they are performed. This is where mismatches between each team member’s understanding of a particular situation can develop.

2.0 Analysis

In this occurrence, the cowl doors on the aircraft’s left engine detached from the nacelle while the aircraft was in climb at approximately 23 000 feet above sea level, leading to an immediate loss of control. Through the investigation, it was discovered that, during the most recent maintenance work on the aircraft, 6 consecutive fasteners securing the left-engine lower cowl door along its front inboard edge had been left unsecured.

This analysis will examine the procedures, practices, and associated human factors involved in the aircraft maintenance work performed. It then discusses training and awareness for maintenance personnel and flight crews when information affecting their fleet is issued by the aircraft manufacturer and regulatory bodies. The analysis also examines the manufacturer’s communication of instruction updates for continuing airworthiness when it identifies issues with maintenance tasks.

2.1 Human factors issues

2.1.1 Slips of attention in skill-based tasks

A maintenance task, such as the reinstallation of engine cowl doors on an aircraft, is a routine and frequently completed task. For experienced aircraft maintenance engineers (AMEs), it is likely that this type of task is performed at a skill-based level of performance, meaning that most or all of their information processing is happening without them consciously thinking about it and, therefore, the task is completed quickly and automatically. At this level of performance, a person’s attention is freed up for other functions because it is not required to complete the task.

In the context of this occurrence, it is likely that the AME who had started by holding up the cowl door experienced a slip of attention when he took over from the other AME on the front edge of the cowl. Taking over from a colleague partway through a task is not part of the AMEs’ usual task sequence; this action provided just enough of a difference from their usual routine for this slip of attention to occur. The AME carried on with the task of securing the fasteners in the order that made sense, given where he had taken over from his colleague.

2.1.2 Task coordination

The AMEs’ common practice with regard to tightening the ¼-turn fasteners was prone to slips of attention such as those described above. By first securing the front- and aft-middle fastener to hold up the cowl door, the AMEs were starting the task of securing the engine cowl door at a halfway point, between the inboard and outboard sides of the nacelle. They then had to tighten the remaining fasteners in 2 separate, non-sequential steps, as opposed to a continuous flow from one side to the other. The task was performed in this manner to facilitate the installation of the cowl by a single AME if a second was not available, improve efficiency when a second AME was present, and ensure a relatively equal balance in securing the fasteners on the cowl door.

However, installing the cowl door this way presented the following issues:

- The ¼-turn fasteners were tightened in a non-sequential order, i.e., middle of the row first, then inboard to outboard on each side. Practised this way, there was an increased probability of fasteners left undone because tightened fasteners were not easily distinguished from undone ones, and they were in difficult-to-see locations, such as on the inboard side of the engine nacelle and underneath the nacelle.

- In cases where 2 AMEs were working together, the non-sequential order and the fact that some of the fasteners were hard to see made it difficult for the AMEs to know where one had left off and where the other was to begin.

In addition, the AMEs’ degree of familiarity with each other and with the routineness of the task likely led them to begin the reinstallation task without much explicit communication or coordination. A pre-task briefing acts as an error-trapping strategy, providing key opportunities to develop among team members a shared awareness of the task to be completed. This is especially important in the context of informal practices being used in the absence of a clearly defined procedure, as was the case in this occurrence. The lack of this type of coordination likely resulted in a mismatch of expectations between the 2 AMEs regarding who was responsible for which aspect of the cowl door installation, which then increased the likelihood of a slip of attention going unnoticed by the 2 AMEs.

The Federal Aviation Administration of the United States (FAA), in releasing a Special Airworthiness Information Bulletin (SAIB) regarding the ¼-turn fasteners, acknowledged the risk of omission when securing these fasteners, even if the SAIB did not fully describe the nature of how the omissions were being made. The SAIB’s focus on inspections offered a useful mitigation.

Finding as to causes and contributing factors

During the reinstallation of the lower cowl doors, the non-sequential order in which the fasteners were tightened likely led to a slip of attention that combined with an unclear expectation on the part of both AMEs about who would be securing the remaining fasteners. As a result, 6 consecutive fasteners were left unsecured.

2.2 Daily inspection

The maintenance work scheduled for the occurrence aircraft 4 days before the occurrence flight consisted of the rectification of reported defects, which involved troubleshooting that required the engine cowl doors to be removed and reinstalled, and a daily inspection (DI) of the aircraft. Both the reinstallation of the left-engine cowl doors and the DI were conducted during the same shift, and both were certified by the same AME who was involved in the final reinstallation of the cowl doors.

Because this AME had just completed and signed for the reinstallation of the cowl doors, he also signed for the DI item related to the condition and security of the left-engine cowl doors without performing a separate inspection specifically for the cowl doors. Surveillance camera footage examined during the investigation verified that the left-engine lower cowl door did not undergo an additional inspection for condition and security after their final installation.

Finding as to causes and contributing factors

The reinstallation of the left-engine cowl doors and the DI were conducted and certified during the same shift and by the same AME. Given that the cowl door reinstallation was completed as part of the maintenance work at the very end of the work shift, the DI item for checking the condition and security of the engine cowl doors was not performed as a specific, separate operation. As a result, the improperly secured condition of the cowl door went unnoticed.

2.3 Flight crew walkaround

Shortly before the occurrence flight, the flight crew conducted 3 walkarounds but did not detect the 6 consecutive unsecured fasteners on the forward inboard edge of the left-engine lower cowl door. Because this location is not easily visible, even from steps away, it can be very difficult to detect an anomaly without looking for it specifically and bending under the nacelle for a direct view. The walkaround guidance material included in Chartright Air Group’s standard operating procedures for flight crews was not specific to lead pilots to look for unsecured fasteners. The flight crew was also unaware of the known safety issues regarding the installation of the engine cowl doors on the occurrence aircraft and other similar aircraft produced by the manufacturer, Textron Aviation Inc. (Textron), that had been communicated by the FAA through an SAIB. Among the issues noted in the SAIB were improperly seated or improperly latched fasteners and cowl doors with excessive forward edge gaps.

Finding as to causes and contributing factors

The location of the unsecured fasteners on the cowl door is not easily visible and was not typically checked during pre-flight walkarounds, and no specific guidance on how to look for unsecured fasteners on this aircraft was available to company flight crews. As a result, the unsecured fasteners went undetected by the flight crew despite their multiple walkaround inspections before the occurrence flight.

2.4 Maintenance personnel and flight crew awareness

The investigation determined that Chartright Air Group’s approved maintenance organization and flight operation personnel did not have easy access to the most recent information and resources from the manufacturer and regulatory bodies regarding the safety concerns related to the installation of engine cowl doors on the Cessna 560 Encore. The AMEs were required to install the engine cowl door per the aircraft manufacturer’s instructions in the maintenance manual. However, the maintenance manual provides the steps for installation only; it does not include details about the known possible issues that could lead to an in-flight separation of the engine cowl doors from the aircraft.

In addition, the flight crew walkaround procedure presented in the company’s standard operating procedures, which include a complete aircraft exterior checklist, did not have a specific check for the engine cowl doors and their proper installation. In this occurrence, the location of the unsecured fasteners was easy to miss without a targeted check of this kind.

The company did not have a process that would have allowed it to capture recommendations issued by the aircraft manufacturer or regulatory authorities. This resulted in lower awareness among flight crews and maintenance personnel of the most recently discovered hazards associated with engine cowl doors on their fleet of aircraft.

Finding as to risk

If operators do not incorporate guidance issued by civil aviation authorities and aircraft manufacturers into their company manuals and procedures, there is a risk that personnel will not be aware of critical flight safety information.

2.5 Aircraft manufacturer’s communications

In light of previous accidents involving engine cowl doors separating from the engine nacelles during flight of aircraft in the Cessna 560 aircraft family, the manufacturer gave a presentation, designed for customers, outlining issues affecting the safe installation of engine cowl doors during its 2022 Textron Aviation Customer Conference. This presentation became available online to customers via the approved Textron’s service network.

Textron’s communication of key takeaways and recommendations, which were based on the critical issues identified, was limited to the content of the presentation, which included the guidance material issued by the FAA in the SAIB. Without new service instructions or revisions to the aircraft maintenance manuals issued by the manufacturer, the maintenance personnel’s knowledge of engine cowl door installation was limited to the most recent procedure described in the maintenance manual. This procedure did not specifically identify the areas of concern communicated in the manufacturer’s conference presentation or in the SAIB. Including this type of information in the maintenance manual would improve technicians’ awareness of the risks associated with the improper installation of the engine cowl doors.

Finding as to risk

If aircraft manufacturers do not incorporate new information regarding known safety hazards into their service instructions and maintenance manuals, there is a risk that maintenance personnel will be unaware of critical safety information during the performance of their work.

2.6 In-flight detachment of engine cowl doors

After the occurrence aircraft had landed at Buffalo Niagara International Airport (KBUF), New York, United States, a remaining portion of the left-engine lower cowl door fell from the aircraft and was recovered. This fragment showed signs of failure of the cowl door material around the fasteners due to aerodynamic forces during the cowl door’s separation from the aircraft.

The 6 consecutive unsecured fasteners left an opening that likely contributed to the creation of a vertical gap between the nacelle inlet assembly and the lower cowl door forward edge, creating air flow inside the nacelle. This flow of air inside the nacelle likely induced vibration and higher tension that the remaining fasteners on the cowl could not withstand, causing the cowl to detach.

The partial detachment of the cowl doors from the nacelle likely produced a sudden parasite drag at the left-engine nacelle, leading to the loss of control and rapid descent of the aircraft. The cowl doors then detached from the nacelle. The investigation also established that a portion of the lower cowl door became lodged on the leading edge of the left horizontal stabilizer before falling off the aircraft while it taxied after landing. The portion of the lower cowl door stuck on the leading edge, in addition to the detachment of the upper cowl door and the rest of the lower cowl door from the engine nacelle, kept the aircraft difficult to control until touchdown.

Finding as to causes and contributing factors

Because some of the fasteners were not secured, there was likely a gap between the cowl door and the nacelle that allowed air to flow inside the nacelle. The cowl doors then partially detached from the nacelle, resulting in the loss of control and rapid descent. Following this, a portion of cowl door became lodged on the horizontal stabilizer and resulted in continued difficulty to control the aircraft.

3.0 Findings

3.1 Findings as to causes and contributing factors

These are conditions, acts or safety deficiencies that were found to have caused or contributed to this occurrence.

- During the reinstallation of the lower cowl doors, the non-sequential order in which the fasteners were tightened likely led to a slip of attention that combined with an unclear expectation on the part of both aircraft maintenance engineers about who would be securing the remaining fasteners. As a result, 6 consecutive fasteners were left unsecured.

- The reinstallation of the left-engine cowl doors and the daily inspection were conducted and certified during the same shift and by the same aircraft maintenance engineer. Given that the cowl door reinstallation was completed as part of the maintenance work at the very end of the work shift, the daily inspection item for checking the condition and security of the engine cowl doors was not performed as a specific, separate operation. As a result, the improperly secured condition of the cowl door went unnoticed.

- The location of the unsecured fasteners on the cowl door is not easily visible and was not typically checked during pre-flight walkarounds, and no specific guidance on how to look for unsecured fasteners on this aircraft was available to company flight crews. As a result, the unsecured fasteners went undetected by the flight crew despite their multiple walkaround inspections before the occurrence flight.

- Because some of the fasteners were not secured, there was likely a gap between the cowl door and the nacelle that allowed air to flow inside the nacelle. The cowl doors then partially detached from the nacelle, resulting in the loss of control and rapid descent. Following this, a portion of cowl door became lodged on the horizontal stabilizer and resulted in continued difficulty to control the aircraft.

3.2 Findings as to risk

These are conditions, unsafe acts or safety deficiencies that were found not to be a factor in this occurrence but could have adverse consequences in future occurrences.

- If operators do not incorporate guidance issued by civil aviation authorities and aircraft manufacturers into their company manuals and procedures, there is a risk that personnel will not be aware of critical flight safety information.

- If aircraft manufacturers do not incorporate new information regarding known safety hazards into their service instructions and maintenance manuals, there is a risk that maintenance personnel will be unaware of critical safety information during the performance of their work.

4.0 Safety action

4.1 Safety action taken

4.1.1 Chartright Air Inc.

Following the occurrence, Chartright Air Inc. grounded its Cessna 560 fleet and inspected the engine cowl doors on each aircraft for damage and proper installation. The occurrence and the inspection resulted in a series of internal safety actions.

4.1.1.1 Internal directive

Immediately following the occurrence, the company’s maintenance department issued Directive DP-79 to all maintenance staff. The directive made the installation of the upper and lower engine cowl doors a critical task, meaning that the task needs to be double-checked for proper installation.

The directive also stated that “No aircraft shall be released for flight if the cowling attachment points do not meet the Aircraft manufacture recommendation. [emphasis in original]” Footnote 34

4.1.1.2 Modification to pilot walkaround standard operating procedures

Following the occurrence, the company reviewed the Exterior Inspection checklist in its flight crew procedures (Flight Crew Standard Operating Procedures, Appendix L) to incorporate an item in the left- and right-engine nacelle checks for the correct installation of the Camloc ¼-turn fasteners. This check is required before each flight.

4.1.1.3 Training of maintenance personnel and flight crews

Training was provided to all maintenance personnel and flight crews regarding how to ensure that the engine cowl doors are installed securely. The training included information about Camloc fasteners and their correct installation, as well as guidance on checking for excessive forward edge gaps on cowl door panels and verifying the structural integrity of the panels.

4.1.1.4 Engineering Authorization C560-54-002: Improved attachment for upper and lower cowl doors

Chartright Air Inc. inspected its Cessna 560 Ultra and Encore fleet and obtained an Engineering Authorization Footnote 35 that provides a minor modification to improve the Camloc attachment durability for the upper and lower cowl doors to the nacelles. The modification consists of adding doubler straps along the cowl door edges at the Camloc fasteners and pitching 4 new threaded screws at each of the cowl door corners.

This report concludes the Transportation Safety Board of Canada’s investigation into this occurrence. The Board authorized the release of this report on 28 February 2024. It was officially released on 27 March 2024.